High-temperature superconducting motor rotor low-temperature cooling system utilizing liquid hydrogen

A motor rotor, high-temperature superconducting technology, applied in superconducting magnets/coils, cooling/ventilation devices, usage of superconducting elements, etc., can solve problems such as inability to meet 30K temperature, high cost of helium pumps, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

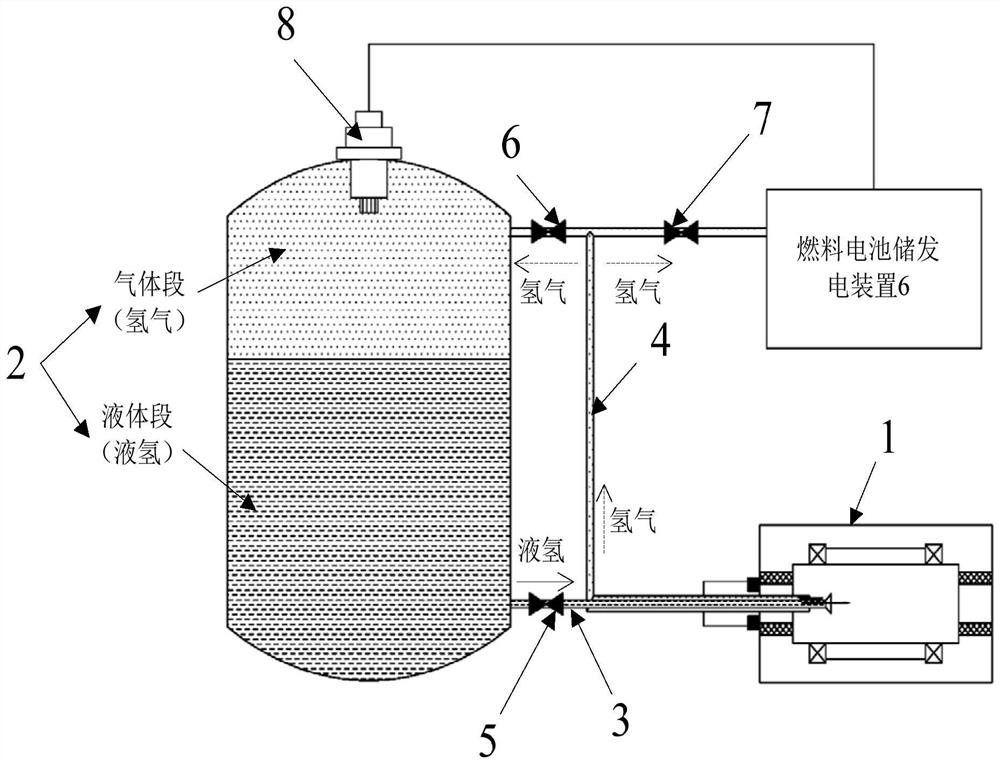

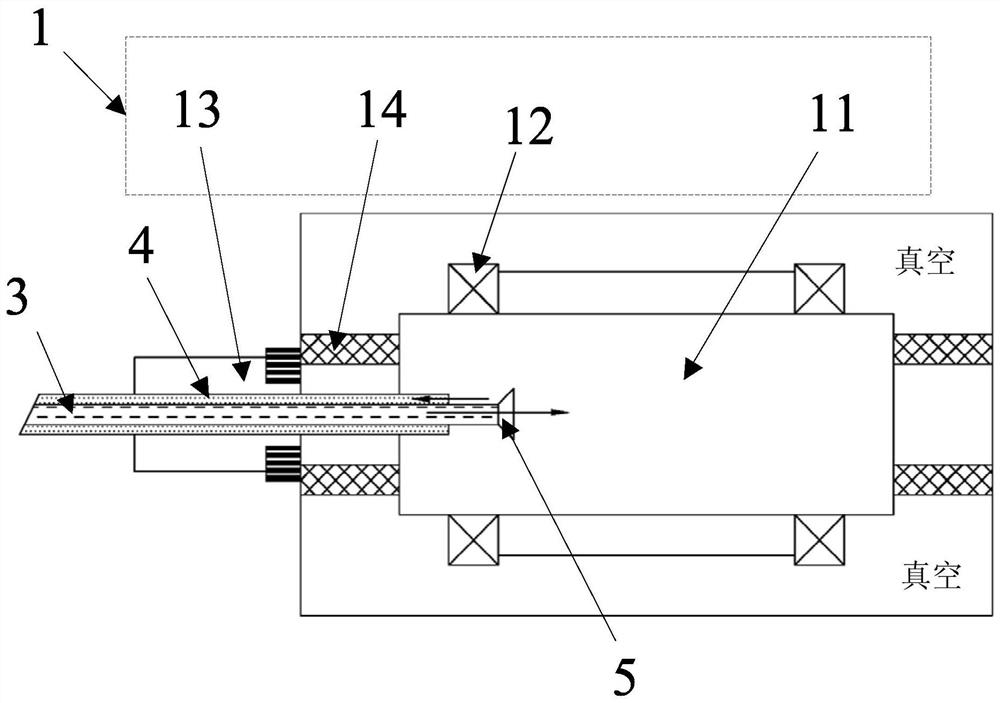

[0027] This application discloses a high temperature superconducting motor rotor cryogenic cooling system using liquid hydrogen, please refer to figure 1 The system block diagram shown and the figure 2 As shown in the partial structural diagram, the system includes a warm superconducting motor rotor 1 , a liquid hydrogen storage tank 2 , a liquid hydrogen delivery pipe 3 and a hydrogen gas delivery pipeline 4 . Among them, liquid hydrogen is stored in the liquid hydrogen storage tank 2, and the liquid hydrogen is the low-temperature cooling medium used for the motor rotor in this application. The inside of the liquid hydrogen storage tank 2 forms a liquid section at the bottom and a gas section at the top, and the liquid section is Liquid hydrogen, the gas section is hydrogen, such as figure 1 shown. The liquid hydrogen storage tank 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com