An integrated device for crimping and testing of overhead transmission line fittings

An overhead transmission line and crimping device technology, which is applied to overhead line/cable equipment, measuring devices, cable installation devices, etc., can solve the problems of damage to the detection object, high labor intensity, and inconvenient detection, and achieve high economical, The operation is difficult and the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

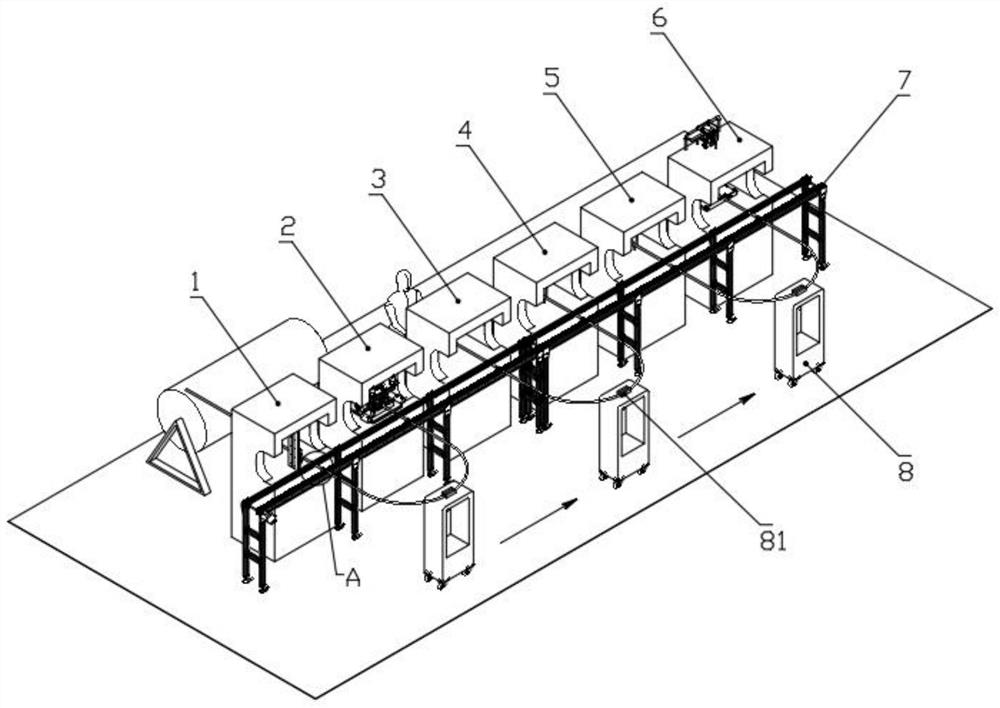

[0041] Attached to the manual figure 1 , Image 6 The shown integrated device for crimping and testing of overhead transmission line fittings includes a power supply unit, a central controller for information processing and instruction sending, and an executive mechanism that acts according to the instructions sent by the central controller. The mechanism includes a conveying device 7 fixedly installed on the ground, a fixed-length wire cutting device 1, a fixed-length stripping aluminum stranded wire device 2, a manual processing platform 3, and Steel anchor tube crimping device 4, wire clip crimping device 5 and X-ray detection device 6;

[0042] An AGV transfer trolley 8 is installed on the other side of the conveying device 7, and the top of the AGV transfer trolley 8 is provided with a second clamp 81 for fixing the power transmission line. One side of the long wire cutting device 1 is bent, and is respectively fixed by a plurality of first clamps 72 fixed on the convey...

Embodiment 2

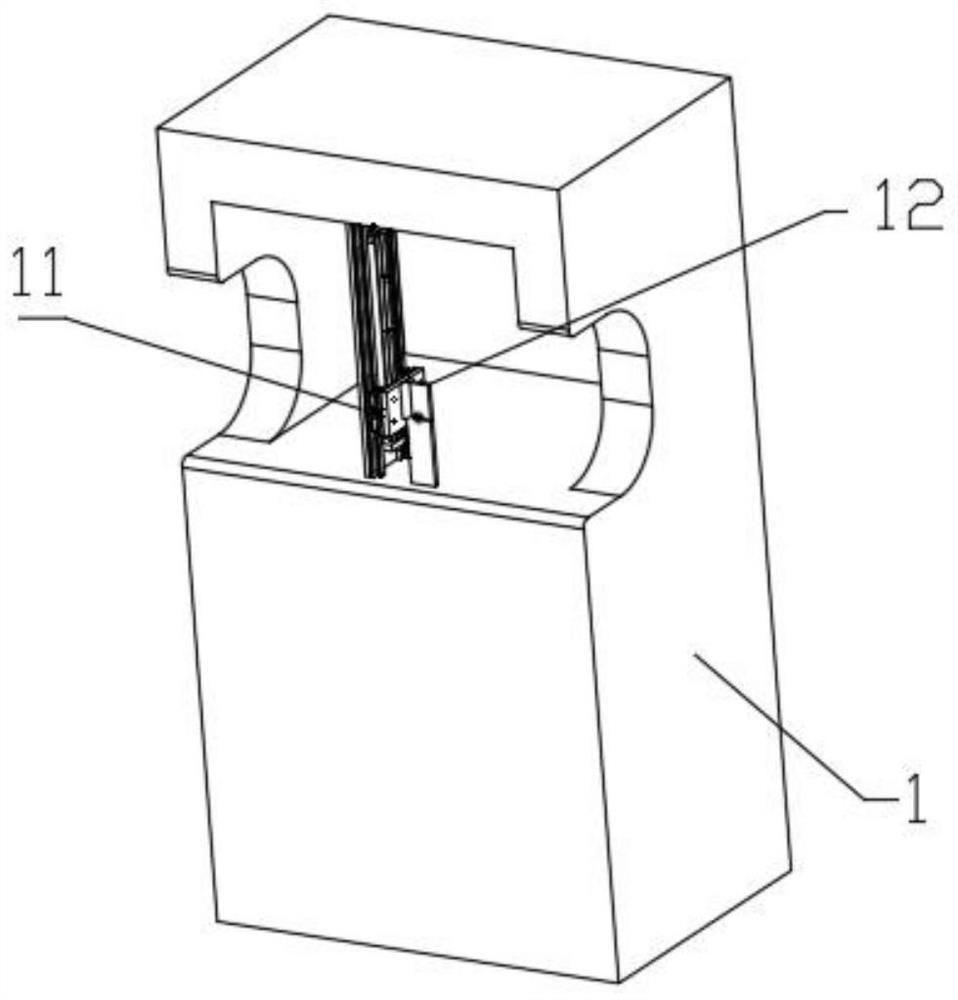

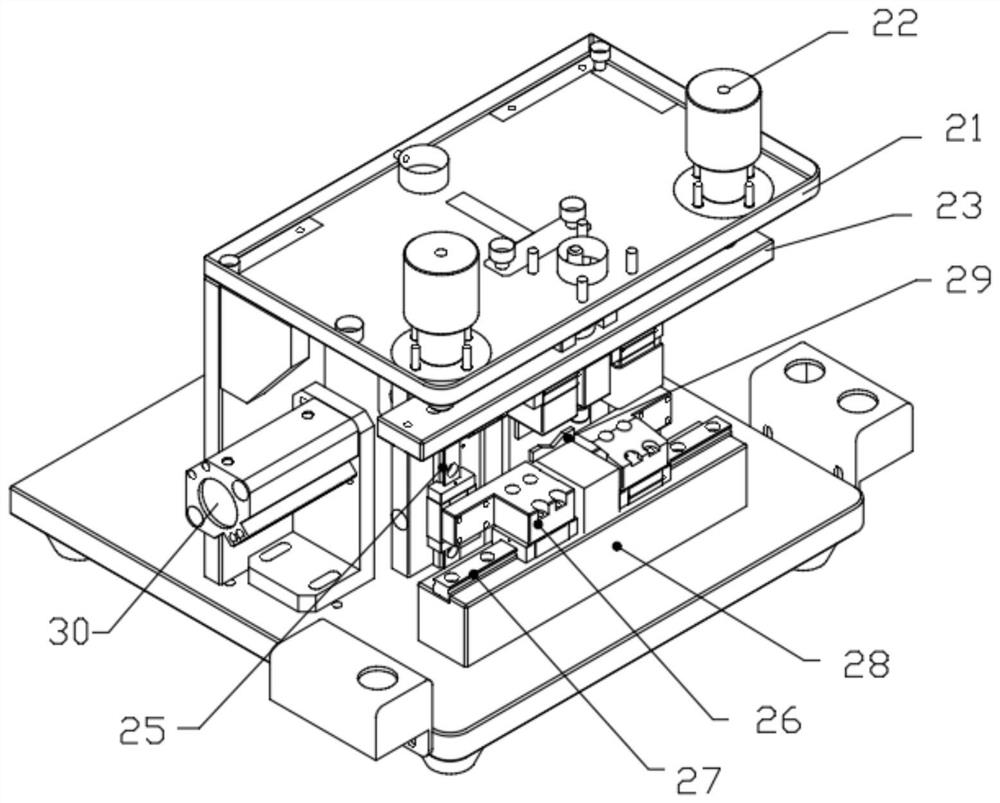

[0054] On the basis of Example 1, in order to further illustrate the technical solution provided by the present invention, the following appendix is further combined with the description. Figure 1-6 As shown, in this embodiment, the fixed-length wire cutting device 1 is equipped with a displacement sensor 11 for detecting the moving length of the transmission line and a device for cutting the transmission line according to the movement distance of the transmission line collected by the displacement sensor 11 reaching a preset threshold value. The wire cutting machine 12, the working axis of the wire cutting machine 12 and the first clamp 72 are located on the same horizontal plane. In this embodiment, the fixed-length aluminum stranded wire stripping device 2 is composed of a body fixedly installed on the ground and a wire stripping mechanism slidably installed on the body;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com