Soilless culture system and soilless culture method

A technology of soilless cultivation and hollow ring, which is applied in the direction of soilless cultivation, cultivation, gardening methods, etc., and can solve the problems that the roots of plants cannot fully absorb nutrient solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

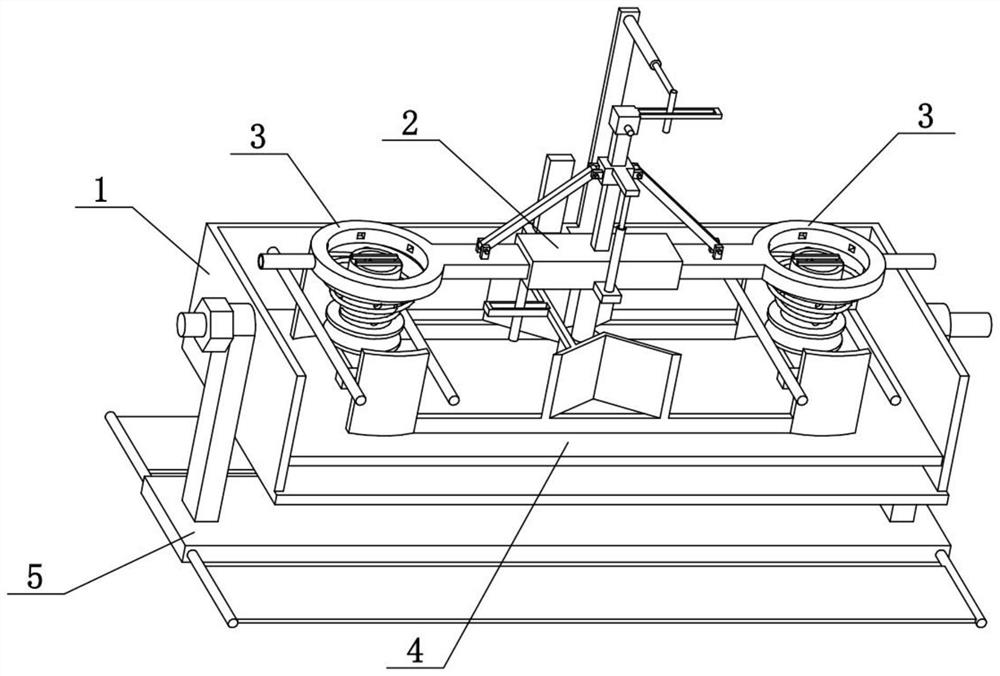

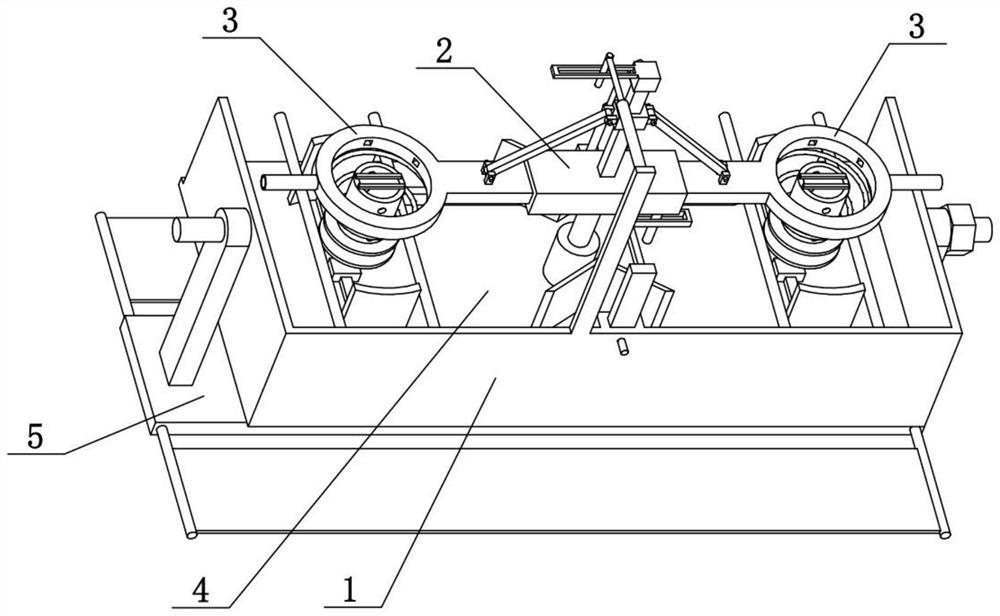

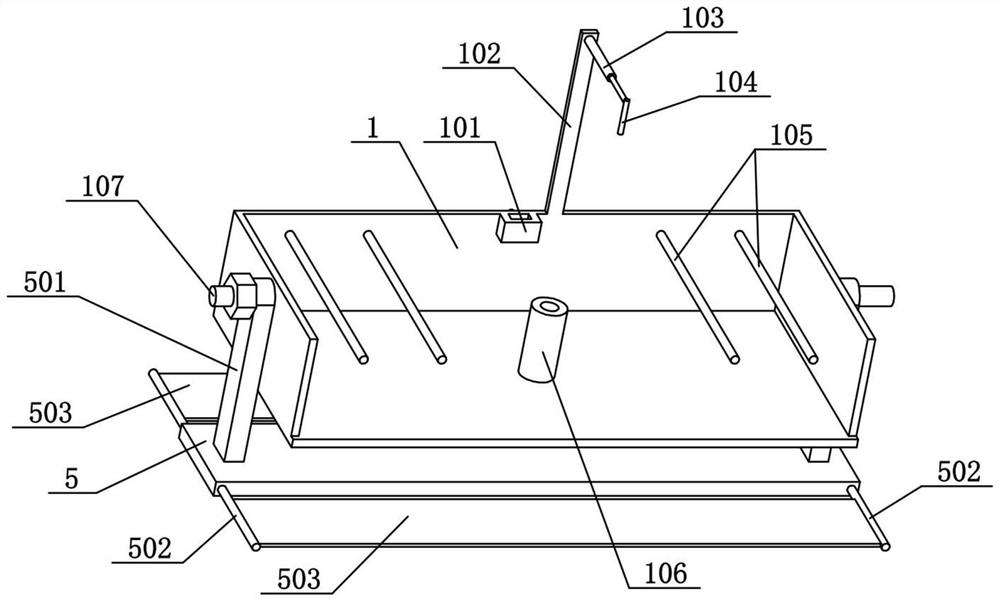

[0034] Combine below Figure 1-8 Describe this embodiment, a soilless cultivation system, including a hollow ring 3, a rubber band 301, a cylinder 304, a conical spring 305 and a liquid inlet 306, and the cylinder 304 is provided with a plurality of liquid inlets 306, The lower side of the hollow ring 3 is fixedly connected with a conical spring 305 , the lower part of the conical spring 305 is fixedly connected with the lower part of the cylinder 304 , and two rubber bands 301 are arranged on the upper side of the cylinder 304 . Insert the plant root into the cylinder 304, and press and fix the upper part of the plant rhizome with two rubber bands 301, then insert the cylinder 304 into the nutrient solution, and the conical spring 305 can be compressed and bent, thereby making the circle The cylinder 304 is inclined relative to the hollow ring 3, so that the plant roots deflect in the nutrient solution, and then the nutrient solution enters the cylinder 304 from the liquid in...

specific Embodiment approach 2

[0036] Combine below Figure 1-8 To illustrate this embodiment, the soilless cultivation system also includes an air jet hole 302 and a joint pipe 303, a plurality of air jet holes 302 are evenly distributed on the inner ring of the hollow ring 3, and a joint pipe 303 is arranged on the hollow ring 3, and the joint pipe 303 It communicates with a plurality of jet holes 302 . The air jet holes 302 are used to inject oxygen or carbon dioxide into the hollow ring 3 4, and the oxygen or carbon dioxide is blown to the plants from the plurality of air jet holes 302, so that the plants absorb oxygen or carbon dioxide, and then the plants are cultivated.

specific Embodiment approach 3

[0038] Combine below Figure 1-8To illustrate this embodiment, the soilless cultivation system further includes a rectangular box 1, an insertion sleeve 106, a middle seat 2, a middle rod 201, a sliding sleeve 202, an electric push rod II205, a fixed shaft 206, a side sliding rod 208 and an equal-length rod 209, the center of the inner side of the rectangular box 1 is fixedly connected with a socket 106, the fixed shaft 206 is inserted on the socket 106, the middle seat 2 is fixedly connected with the upper end of the fixed shaft 206, and the upper side of the middle seat 2 is fixedly connected with a middle rod 201, The middle rod 201 is vertically slidably connected with a sliding sleeve 202, the left and right sides of the sliding sleeve 202 are hinged with equal length rods 209, the left and right ends of the middle seat 2 are slidingly connected with side sliding rods 208, two equal length rods 209 The other ends of the two side sliding rods 208 are respectively hinged, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com