Carbonation tower and carbonation system

A technology of carbonation tower and tower body, which is applied in the direction of ammonium carbonate/acid carbonate, carbonate preparation, bicarbonate preparation, etc., which can solve the heat exchange and nucleation speed of tower walls that are easy to scab Slow and other problems, to achieve high efficiency, speed up the absorption process, and the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

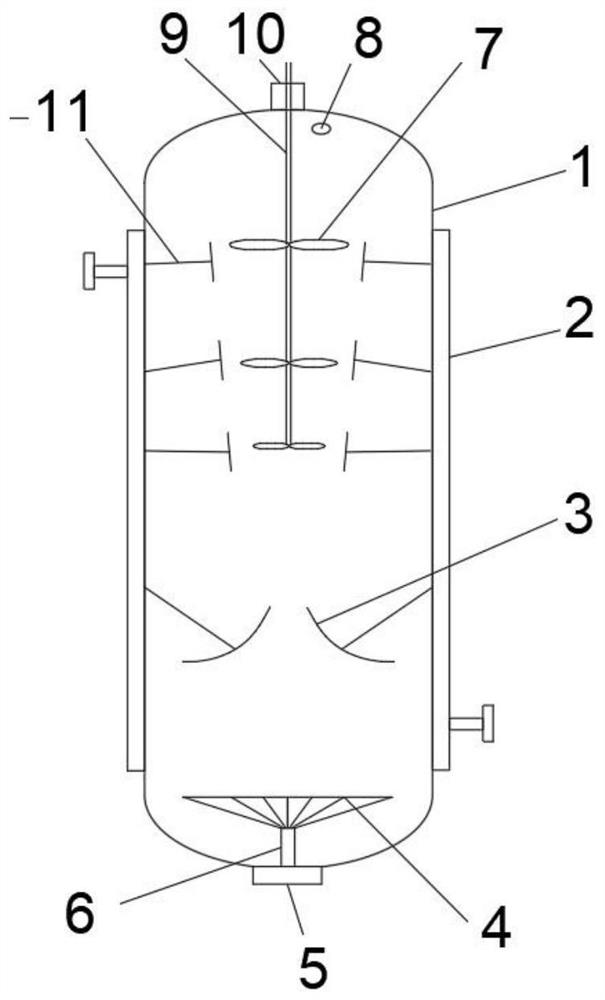

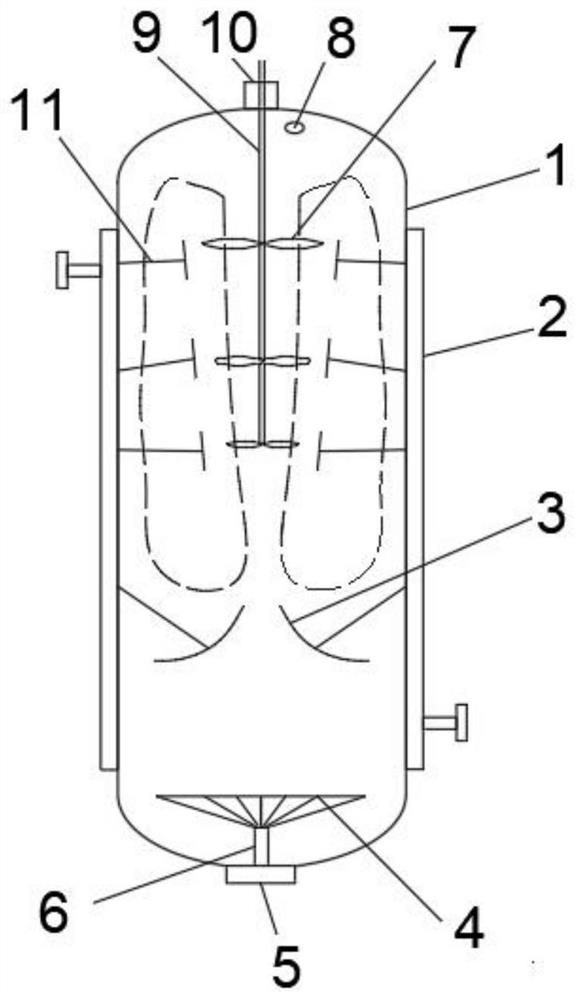

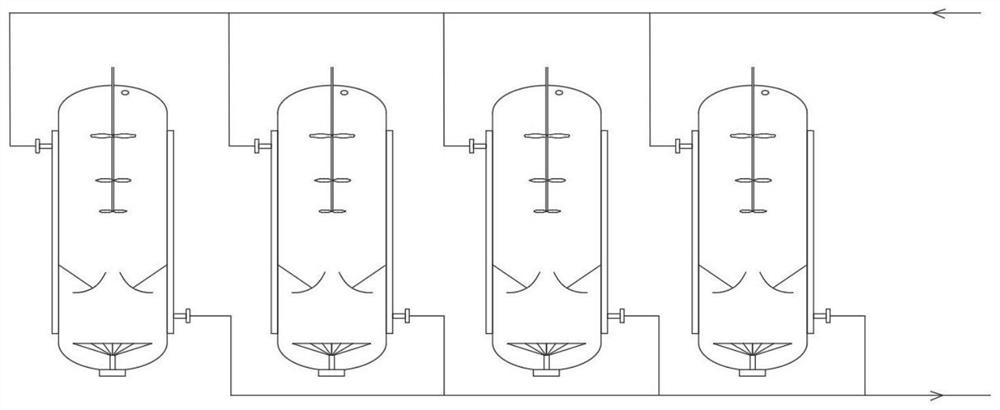

[0025] Such as figure 1 As shown, the carbonation tower of the present invention includes a tower body 1, a cooling water jacket 2, an air inlet pipe 6 arranged at the bottom of the tower, an air outlet pipe 10 arranged at the top of the tower, a feed inlet 8 and a discharge outlet 5, arranged in the tower A stirring shaft 9 inside the tower body, and a stirring blade 7 fixed on the stirring shaft 9, and a spoiler 3 is fixed inside the tower body.

[0026] The gas distribution plate 4 is disc-shaped, and the disc surface is provided with some exhaust holes, and any exhaust hole is connected with the air intake pipe 6 and is provided with such as figure 1 The passage shown in the figure ensures that the carbon dioxide gas flow can evenly fill the entire carbonation tower and fully contact with the feed liquid.

[0027] Compared with the Solvita of the prior art, the carbonation tower provided by the present invention is provided with a stirring structure inside, and the settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com