Rice milk production system with circulating cleaning function

A production system and rice milk technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as waste, achieve convenient recycling, save water resources, improve efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

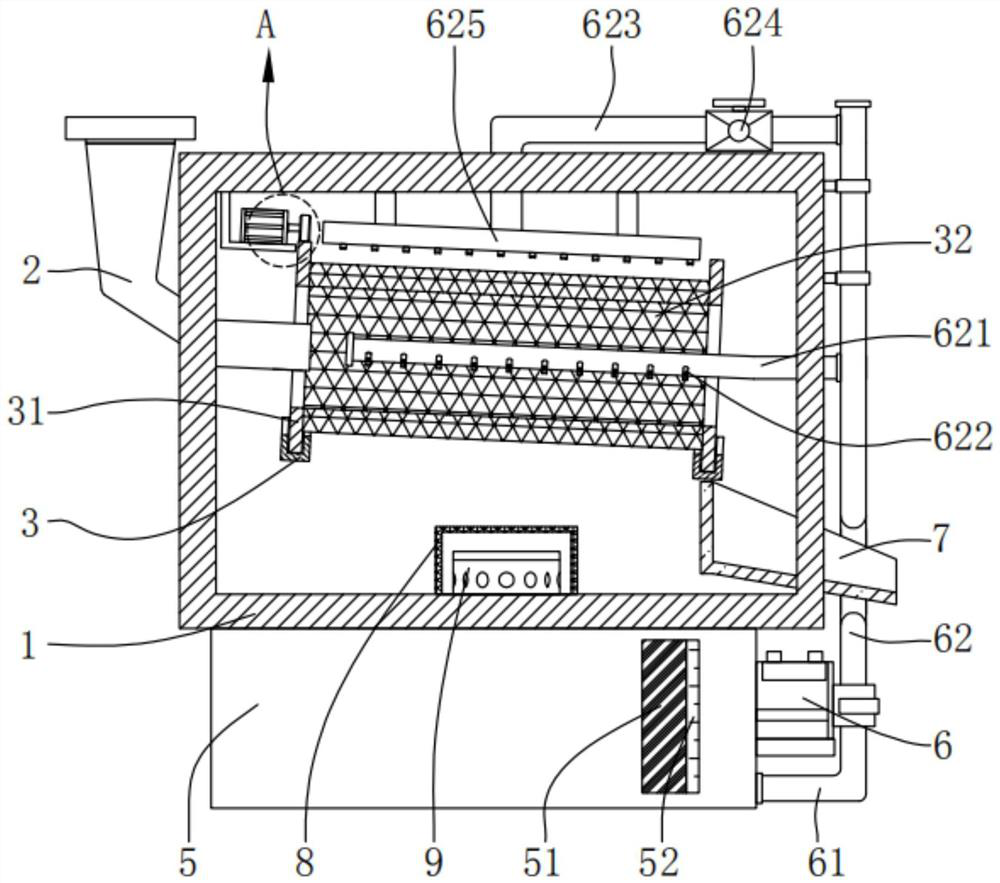

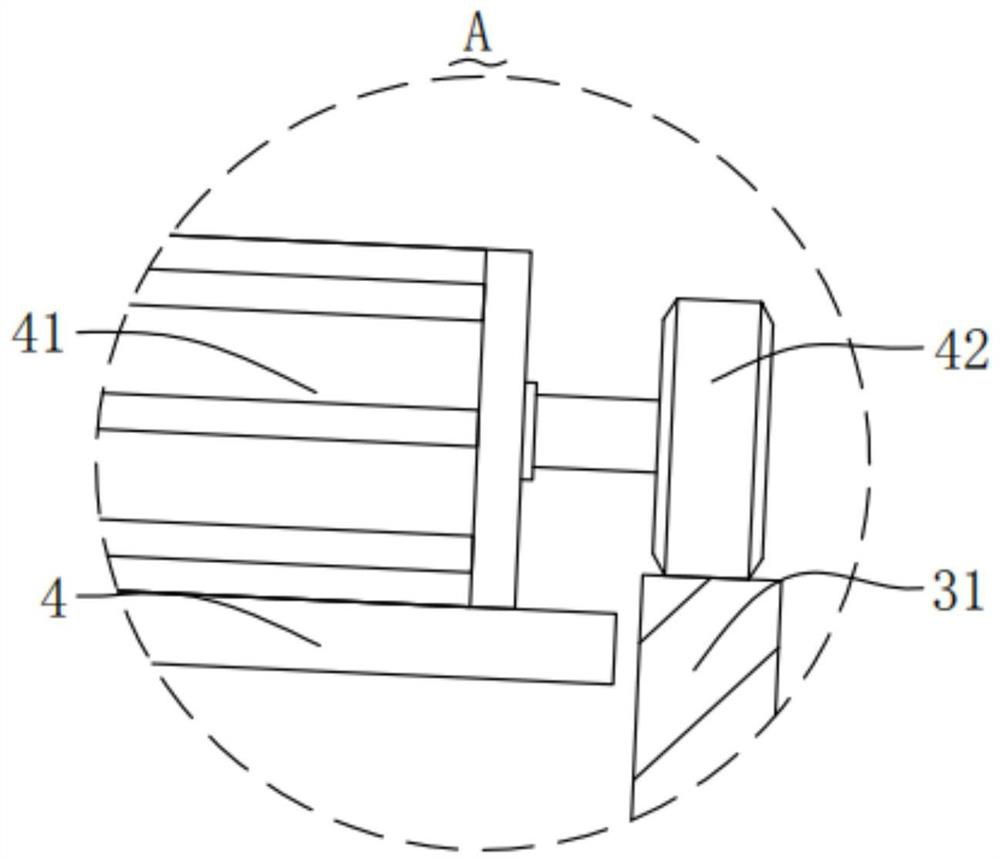

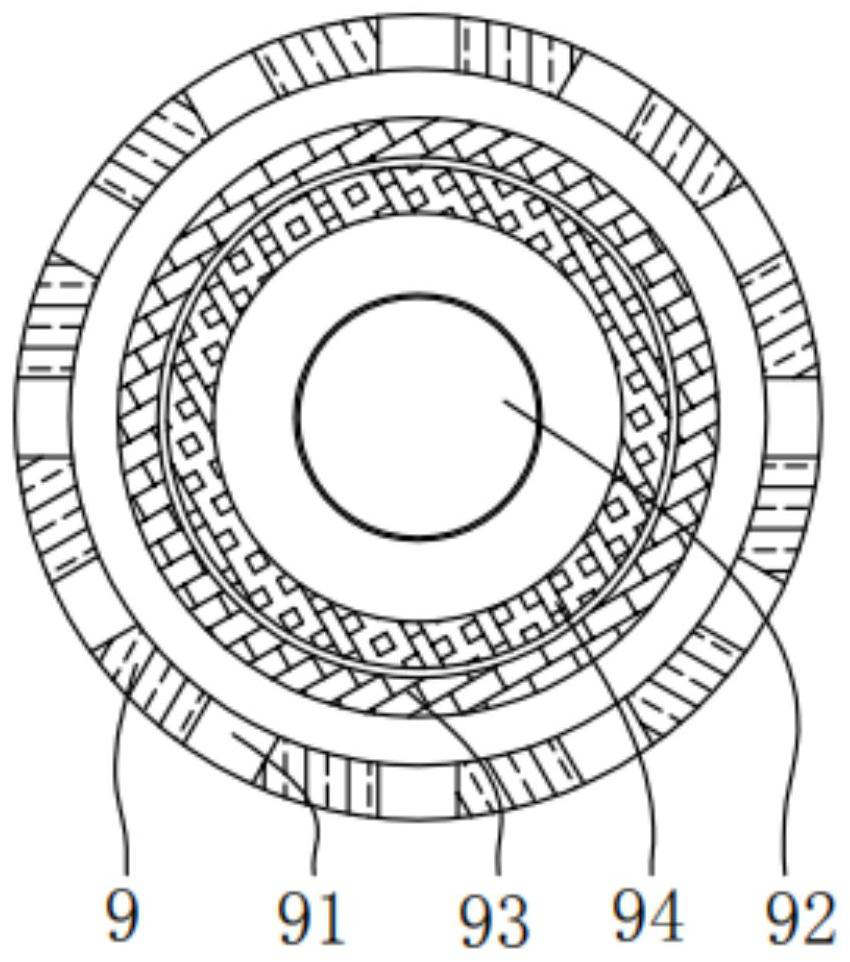

[0024] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the rice milk production system with the circulation cleaning function provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 The schematic diagram of the structure of the water inlet box shown; Figure 4 for figure 1 Schematic diagram of the structure of the part of the flushing line shown.

[0025] A rice milk production system with a cycle cleaning function comprising: a box body 1; a feed port 2, which is arranged on one side of the box body 1; a support frame 3, which is fixed On the inner wall of the box body 1, the top of the support frame 3 is rotatably connected with a linkage plate 31, and the linkage plate 31 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com