Technology for printing different interlayer colors through 405nm DLP

A color and process technology, applied in the field of 3D printing, can solve the problems of restricting the application and promotion of DLP printing equipment, restricting the application of DLP printers, and product performance cannot be changed, so as to achieve the effect of improving aesthetic value, uniform pigment mixing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

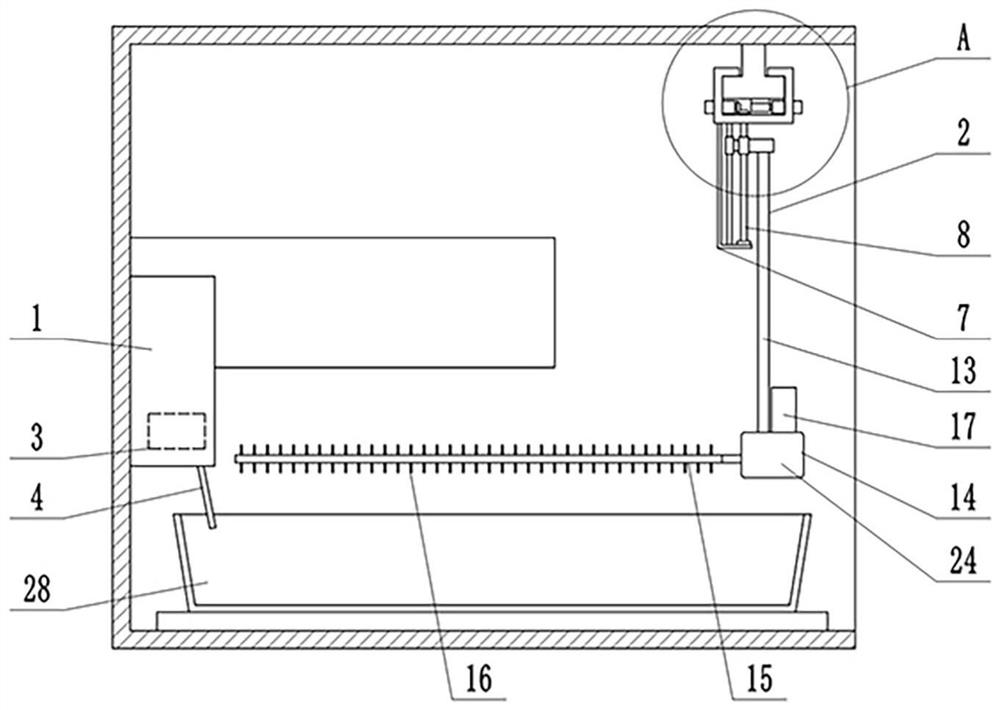

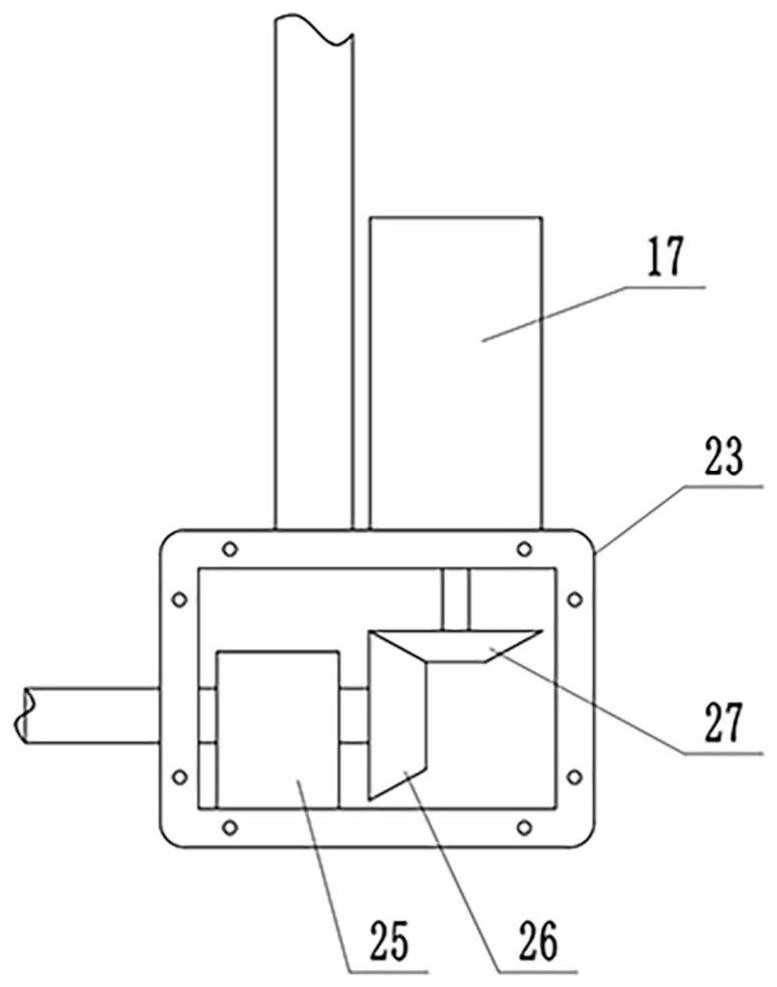

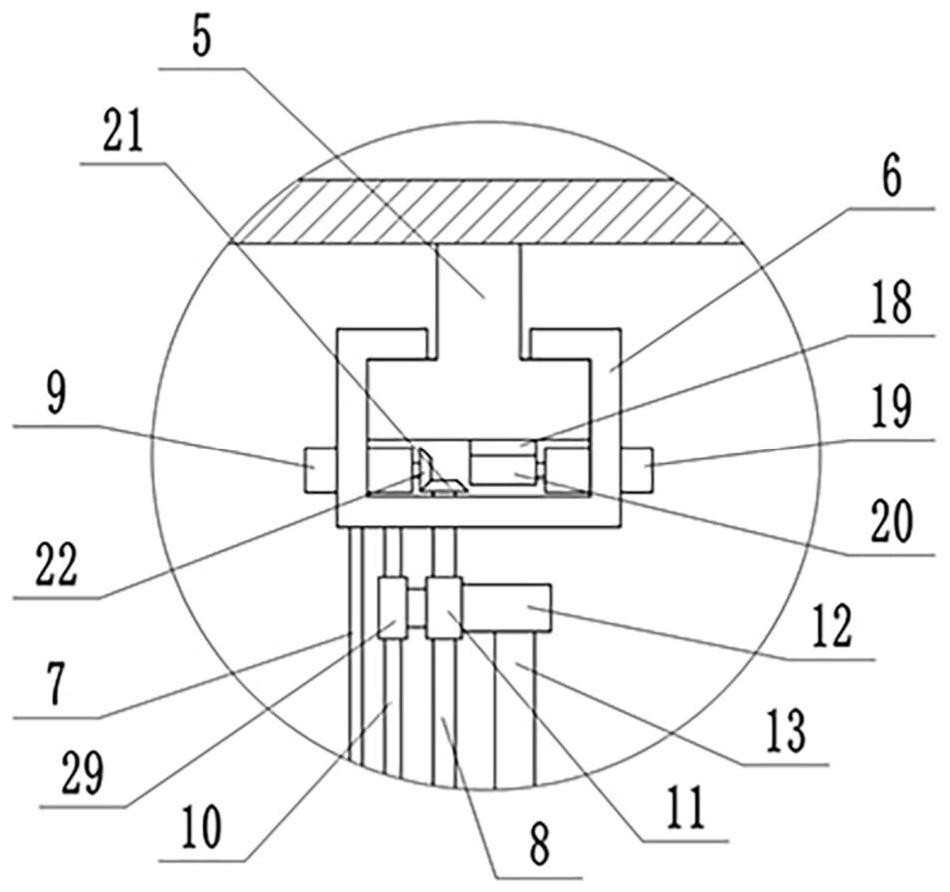

[0021] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] A 405nm DLP process for printing different interlayer colors, which is operated according to the following steps,

[0023] a. Use drawing software to create product models and generate .stl data model files;

[0024] b. Import the .stl data model file into the Dolphin Studio slicing software, slice the data model according to the set thickness of each layer, and generate a .3dp print trajectory file;

[0025] c. Import the .3dp print track file into the DLP printer, add photosensitive resin to the resin tank of the DLP printer, set the printing parameters, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com