Multi-shot continuous launching test platform

A test platform and projectile technology, applied in the field of test platforms, can solve problems such as the complex structure of shot peening equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

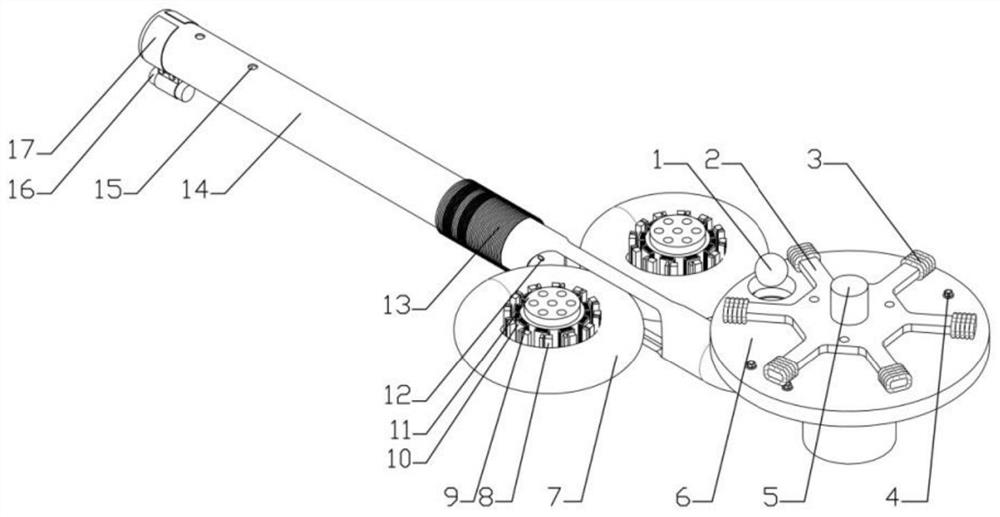

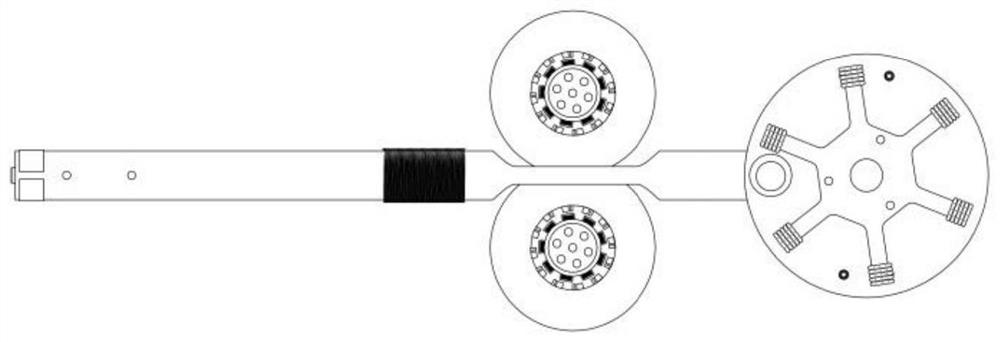

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 8 , The projectile dial 2 and the cylindrical platform 6 are installed on the motor output shaft with the base hole system, and then the output shaft is driven by the variable speed motor to rotate at a suitable speed. The projectile rolls down from the inclined surface of the magazine 20, and falls into the curved tube of the plastic launch tube through the projectile dial 2. Wherein the magazine and the variable speed motor etc. are all welded on the fixed panel 21 of the truss.

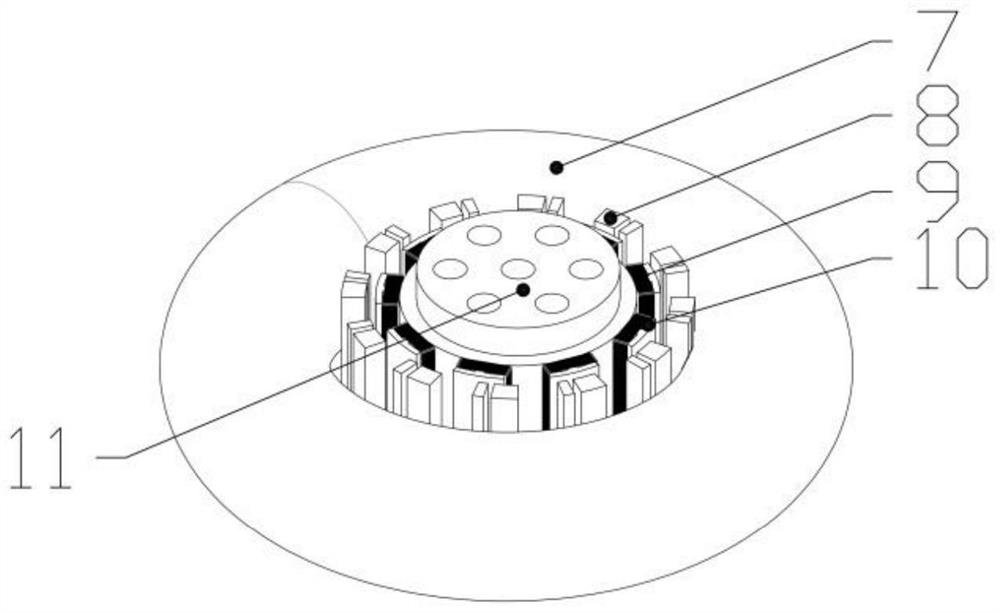

[0024] After the projectile falls into the curved tube, it will be given an initial velocity by the projectile driving device. Such as image 3 , the rotor shaft 11 of the driving device is made into honeycomb coal shape to reduce its weight, so as to ensure quick start when energized. The permanent magnet coil frame 10 and the rotor shaft 11 are also matched thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com