Lap joint welding quality defect prediction method and system and computer readable storage medium

A technology for welding quality and lap joints is applied in the field of welding quality defect prediction of lap joints, which can solve the problems of misjudgment of welding defects and fluctuation of welding parameters, and achieve the effect of enhancing the recognition ability and deleting unbelievable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

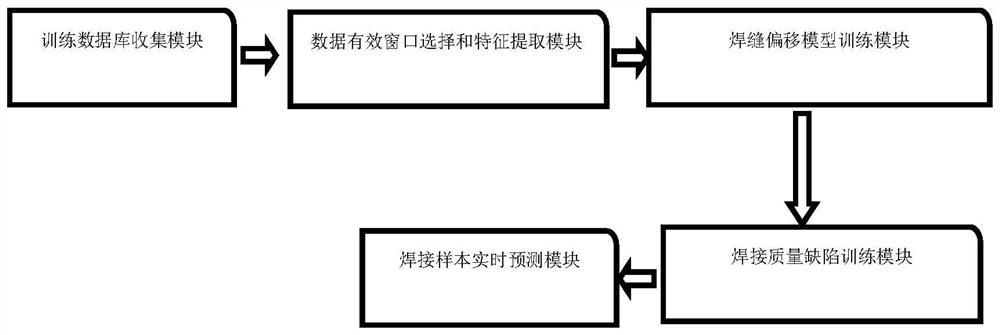

[0027]Such asfigure 1 Shown is a schematic flow diagram of a method for predicting weld offset according to the present invention.

[0028]According to a method for predicting weld migration according to the present invention, the method for improving predictive weld migration includes the following steps:

[0029]1) Training database collection module: Collect 210 arc voltage and welding current data of welding robots through the industrial gateway, and manually label the center of the welding seam offset from the center of the welding wire. When the upper board is offset, it is recorded as a=1, when the lower board is offset The time is recorded as a=2, and the unbiased condition is recorded as a=0. At the same time, the welding quality is manually labeled. When there is a welding defect, it is recorded as y=1, otherwise it is recorded as y=0, and all data and labels are used as training Library

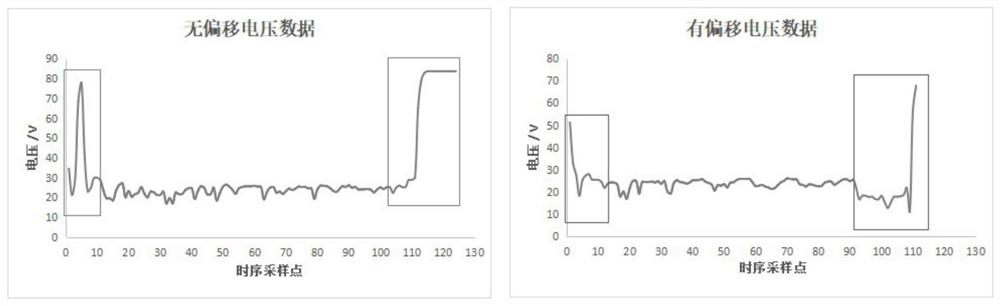

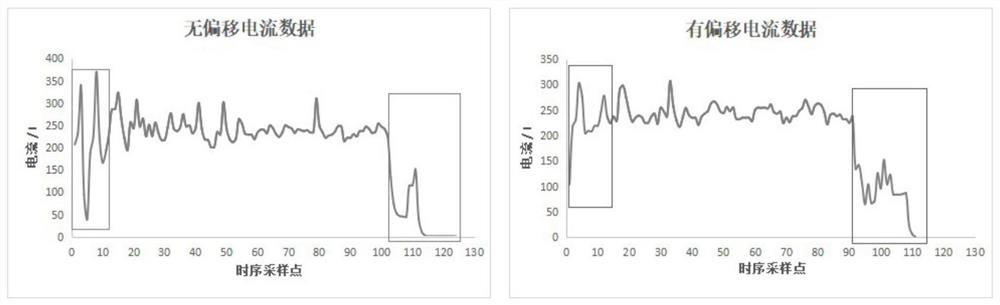

[0030]2) Extract data valid window and characteristics: extract the collected arc voltage and...

Embodiment 2

[0056]This embodiment discloses a system for predicting welding quality defects of lap joints, and the system includes:

[0057]Training database module, the training database module contains the arc voltage and welding current data of the welding robot collected through the industrial gateway, the training data module includes label data on the situation that the center of the weld is offset from the center of the welding wire, and the label of the welding quality Data, the training data module also includes all electrical parameter data;

[0058]Data valid window and feature extraction module, the data valid window and feature extraction module extract the collected arc voltage and welding current data according to the valid window, delete the beginning and end data affected by arc start and end, adopt Greek The Erbert transform method calculates the time variation, and extracts the features of the parameters in the effective window respectively;

[0059]A weld offset model training module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com