A charging ripple suppression circuit of an on-board charger and its control method

An on-board charger and ripple suppression technology, applied in battery circuit devices, efficient vehicle charging, electric vehicle charging technology, etc., can solve problems such as increasing product cost, reducing system bandwidth, and reducing product service life, and achieving extended use. longevity, improving product performance, and suppressing low-frequency ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In the field of electric vehicles, the stability of the on-board charger has always been an important condition for the efficient output of electric vehicles, but when the charger is working, the DC bus output by the output circuit will have low-frequency ripples twice the power frequency, and the existence of low-frequency ripples may As a result, the battery management system (BMS) calculates the remaining power (SOC) inaccurately. In severe cases, it may cause overcharge, affecting battery life and safety. Therefore, in order to improve the working stability and high performance of the charger, the embodiments of this specification provide a charging ripple suppression circuit for an on-board charger, which can suppress the above-mentioned low-frequency ripple.

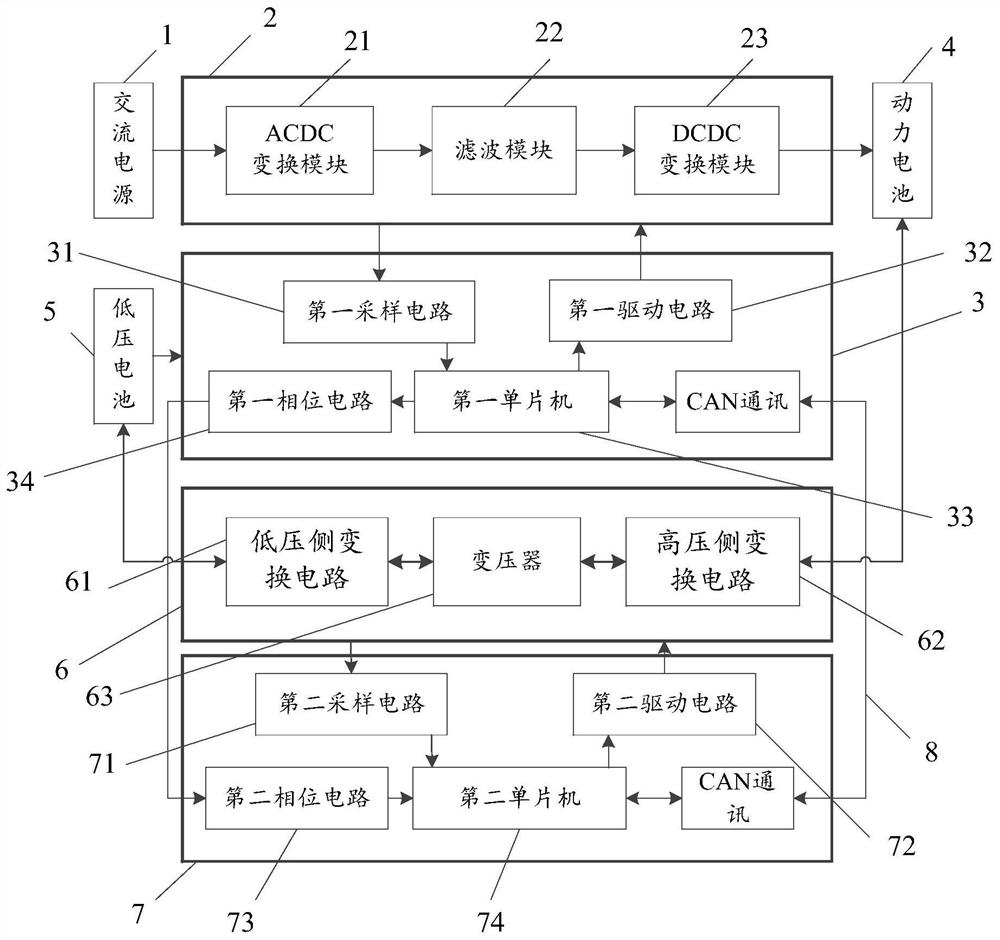

[0065] Specifically, as figure 1 As shown in the figure, a schematic diagram of the connection of a charging ripple suppression circuit of an on-board charger (OBC) provided by the embodiment of this specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com