Hammering device for food processing

A hammering device and food processing technology, applied in the field of food processing, can solve the problems of physical strength, consumption, and affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

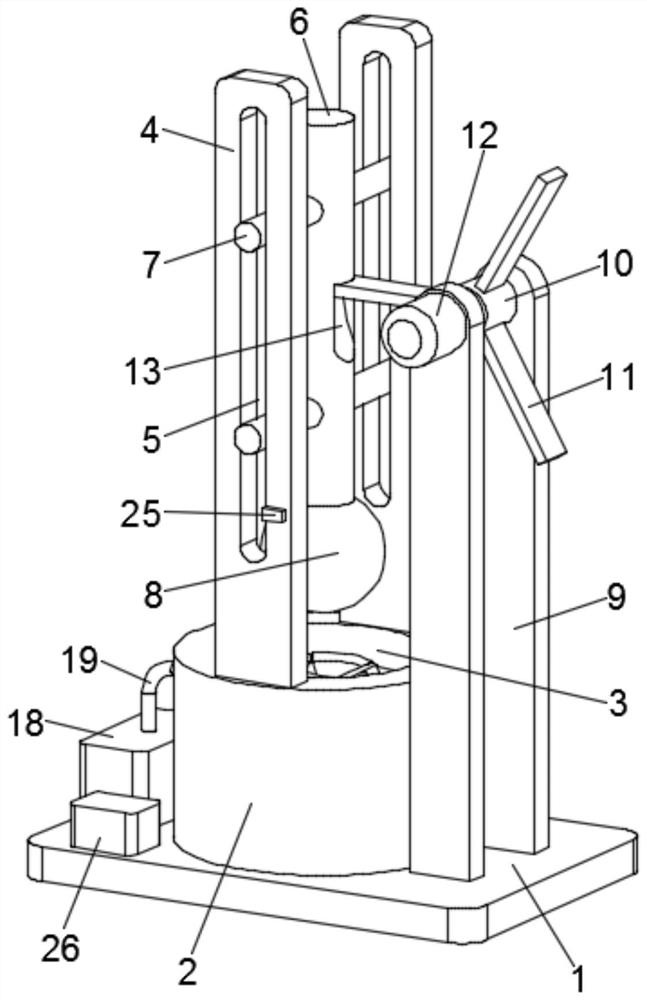

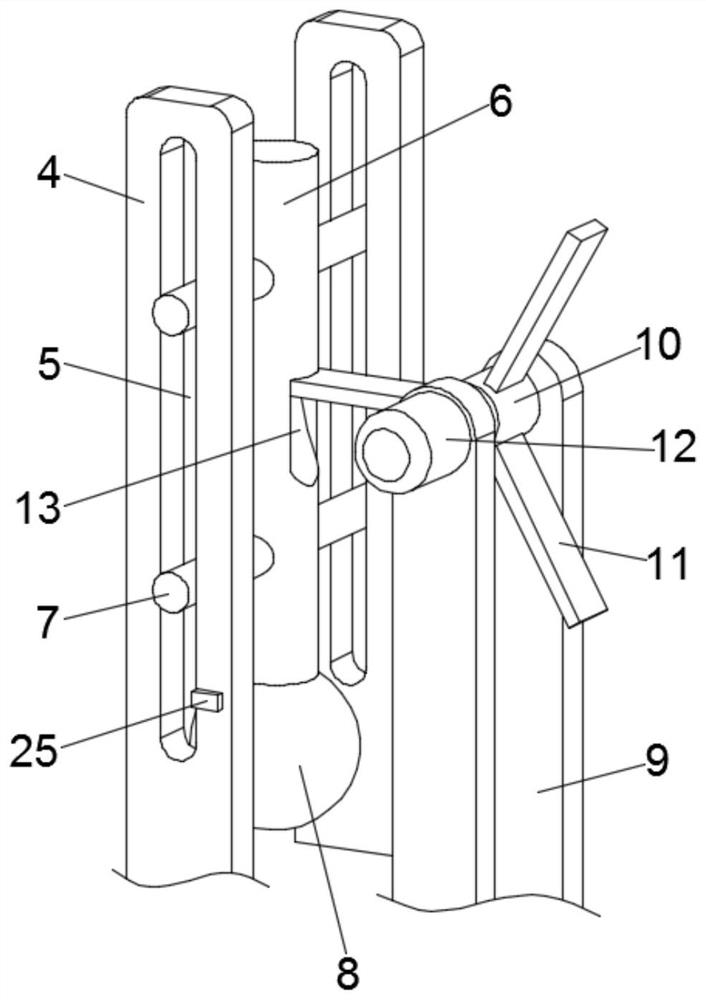

[0024] see figure 1 , a hammering device for food processing, comprising a base 1, a material holding platform 2 and a mounting column 6, the upper end surface of the base 1 is fixedly equipped with a material holding platform 2, and an accommodating chamber 3 is opened in the material holding platform 2, The first supporting frame 4 is vertically installed symmetrically on both sides of the upper end surface of the storage platform 2, and a through groove 5 is vertically opened in the first supporting frame 4, and sliding cards are fixed on both sides of the mounting column 6. The slide bar 7 in the through groove 5, the hammer head 8 is fixed on the bottom of the mounting column 6, and the lifting mechanism for the vertical lifting of the mounting column 6 is installed on the base 1;

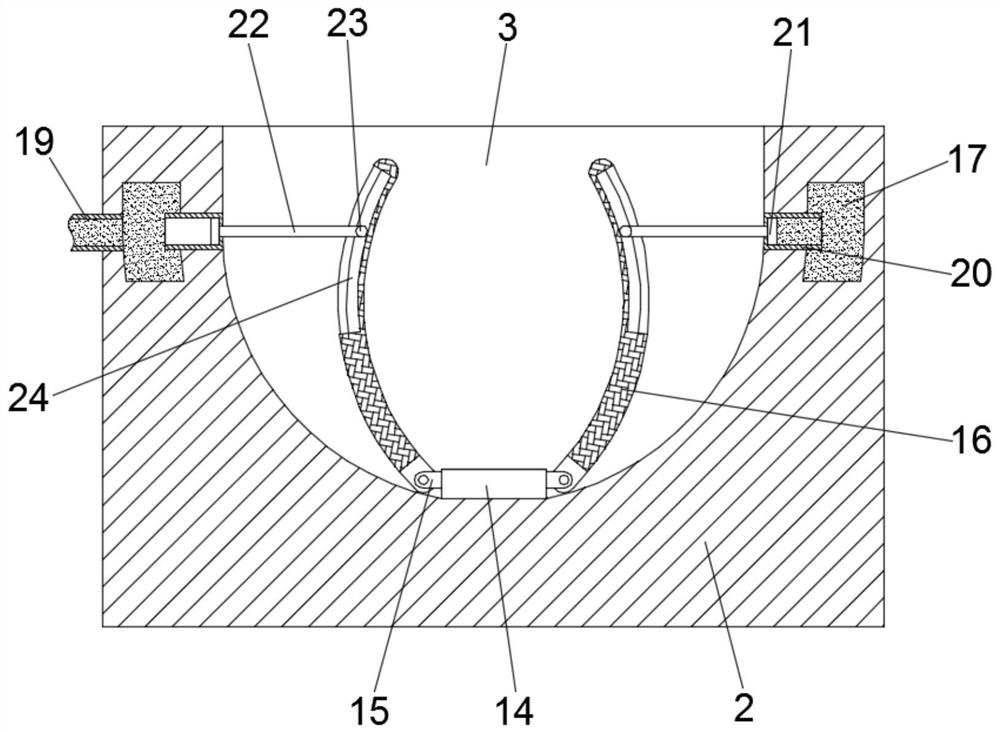

[0025] see figure 2 , the inner bottom of the housing chamber 3 is equipped with a fixed seat 14, and the outer cylindrical surface of the fixed seat 14 is evenly distributed with a number o...

Embodiment 2

[0036] see Figure 4 In order to realize the alternating and orderly execution of the hammering action of the hammer head 8 and the gathering action of the top plate 16, this embodiment has been further improved on the basis of Embodiment 1. The improvement is: the bottom of the first support frame 4 is provided with a For detecting the sensor 25 of the slide bar 7, a controller 26 for receiving the signal of the sensor 25 and controlling the operation of the drive motor 12 and the hydraulic drive device 18 is installed on the base 1;

[0037] Specifically, when the hammer head 8 is lifted again by the lifting plate 11 after falling, the sensor 25 detects that the slide bar 7 is far away, thereby sending a falling edge signal to the controller 26, and the controller 26 controls the hydraulic drive device 18 after receiving the falling edge signal. Running, drives the top plate 16 to rotate, gathers food, then top plate 16 resets, waits for hammer head 8 to fall again;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com