Heavy-duty compaction device

A compactor and heavy-duty technology, which is used in basic structure engineering, on-site foundation soil survey, soil material testing, etc. Precise clamping and even hammering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

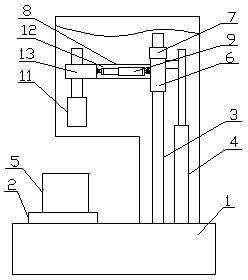

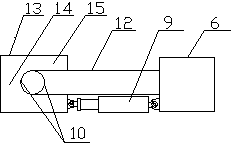

[0011] Such as figure 1 with figure 2 As shown, a heavy-duty compaction instrument includes a base 1, a rotary table 2 arranged on the base 1, a guide column 3, a hydraulic cylinder I4, and a control system. The drive mechanism that is arranged inside the base 1 and can drive it to perform intermittent rotational movement in the horizontal plane is connected. The guide post 3 is vertically arranged on one side of the turntable 2, and a slide block 6 is slid on the guide post 3. A positioning block 7 fixed on the guide column 3 is arranged above the slider 6, and a pressure sensor is provided at the bottom of the positioning block 7, and one side of the slider 6 is connected with a pin and a hydraulic cylinder I4 for driving it to move up and down. The lifting end is connected, and the other side of the slider 6 is provided with a cantilever 8, and the cantilever 8 is composed of a fixed arm 12 and a sliding arm 13 that are slidingly fitted, and one end of the fixed arm 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com