Shielding gas plugging tooling for butt welding of steel pipes

A technology for shielding gas and steel pipes, which is used in devices for supplying/exhausting shielding gas, welding equipment, welding accessories, etc., which can solve the problems of inability to displace the air as a whole, long replacement time, and increased argon consumption, so as to improve the weld seam. High quality, good effect and less welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

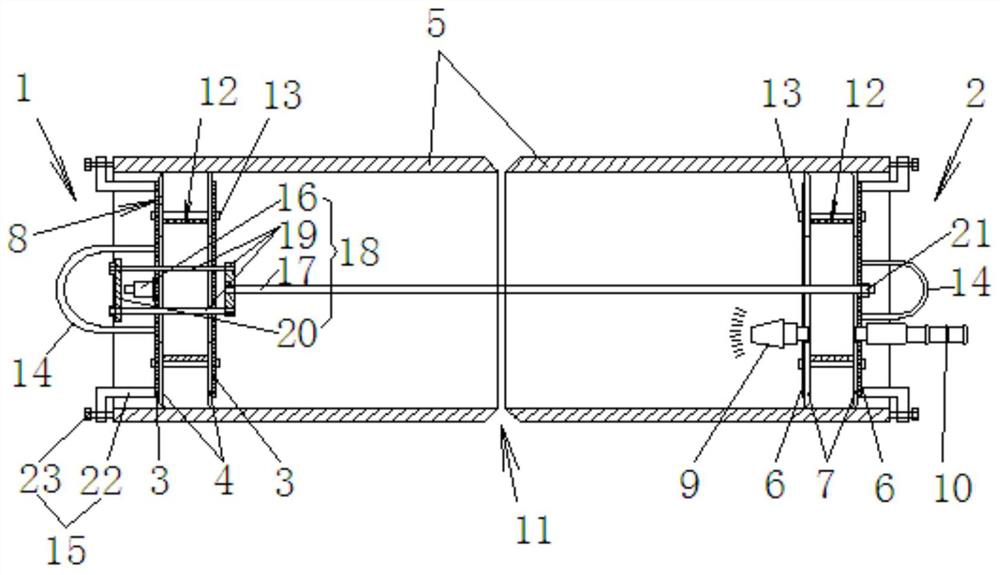

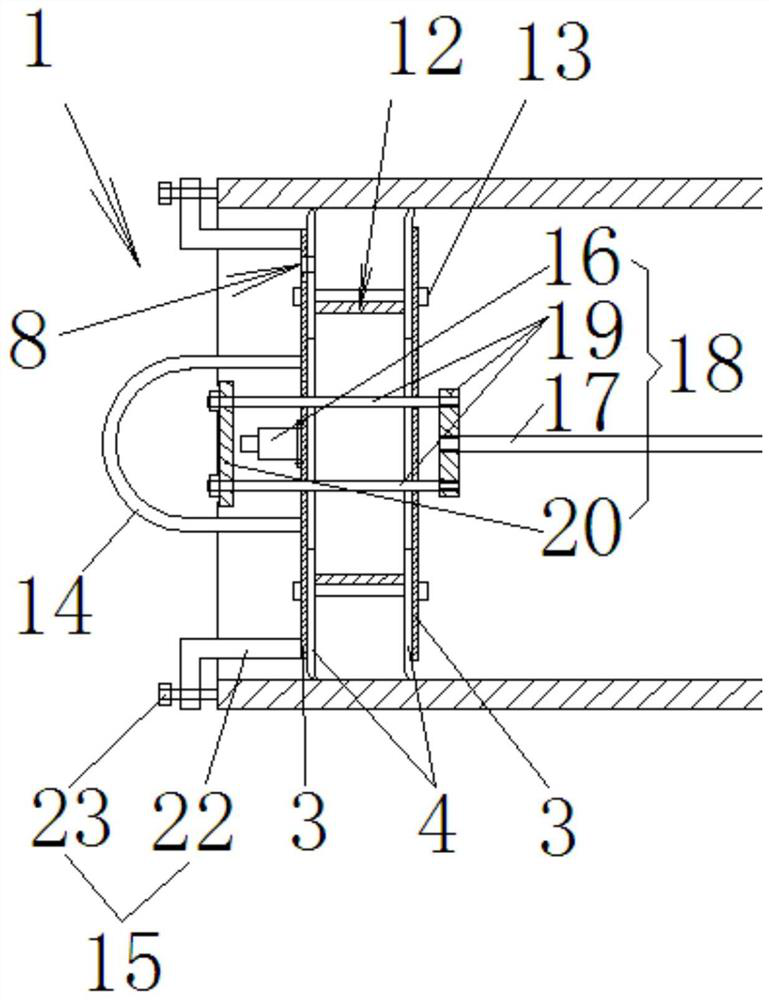

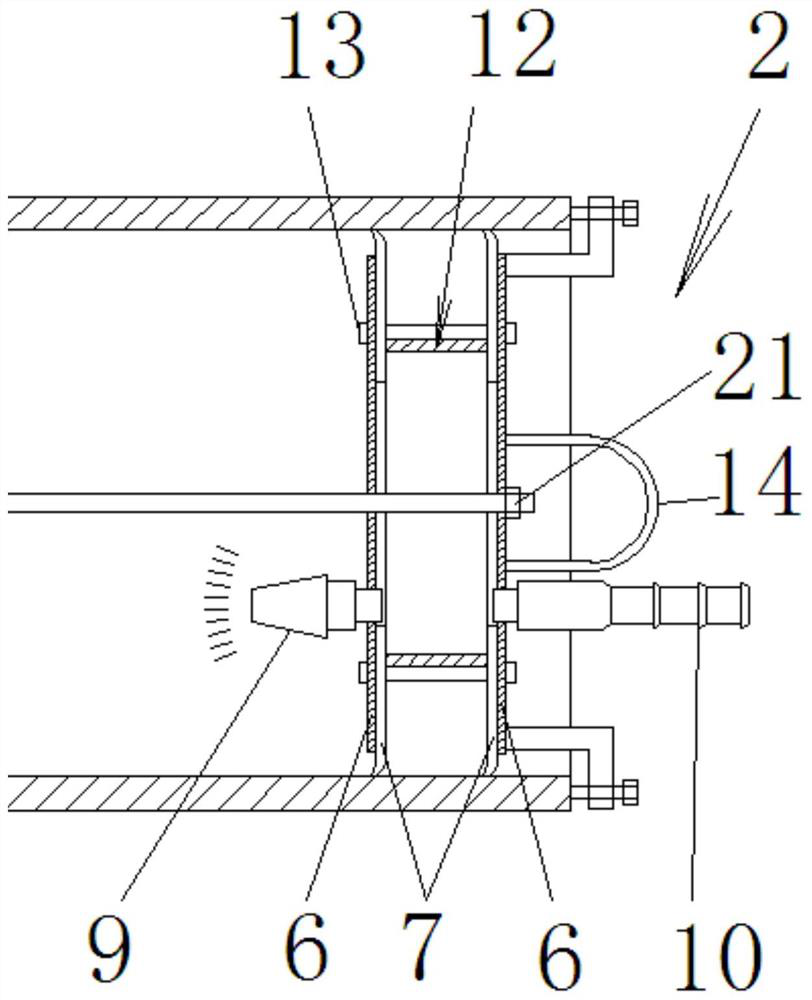

[0027] Such as Figures 1 to 4 Shown is an embodiment of a shielding gas plugging tool for butt welding of steel pipes according to the present invention, which includes a first plugging assembly 1 and a second plugging assembly 2, and the first plugging assembly 1 includes a first rigid The support plate 3 and the first rubber seal 4 connected to the first rigid support plate 3, the outer circle of the first rubber seal 4 is in sealing fit with the inner diameter of the steel pipe 5; the second blocking assembly 2 includes The second rigid support plate 6 and the second rubber seal 7 connected to the second rigid support plate 6, the outer circle of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com