High-strength industrial waste residue treatment device with filtering function

A technology for filtering and industrial waste residues, applied in heating devices, manufacturing tools, transportation and packaging, etc., can solve problems such as injury to workers, inability to effectively dry waste residues, and inability to filter and separate waste liquids, so as to avoid environmental problems. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

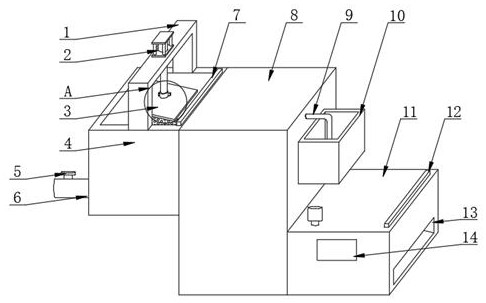

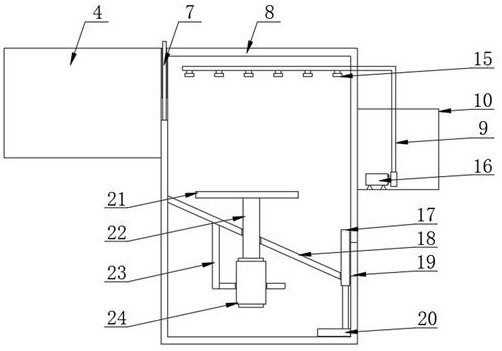

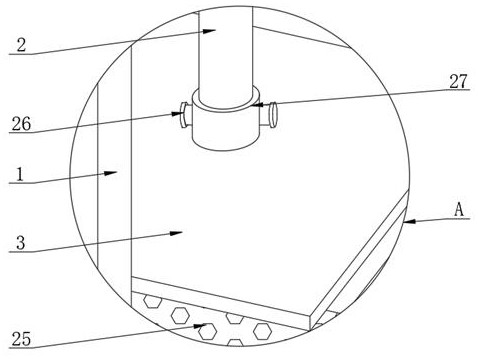

[0026] see Figure 1~6 , in the embodiment of the present invention, a high-strength and filtering industrial waste residue processing device includes a processing box 8, a filter box 4 is integrally installed on the upper half of one side of the processing box 8, and the telescopic end of the cylinder 2 is embedded Mounting sleeve 27 is installed, and the outside of mounting sleeve 27 is provided with through hole, and the flexible end of cylinder 2 is provided with screw hole, and the exterior of mounting sleeve 27 is symmetrically installed with mounting bolt 26 and one end of mounting bolt 26 runs through mounting sleeve 27 external openings. The through hole extends to the screw hole provided inside the cylinder 2 and is threadedly connected with the screw hole. The lower surface of the mounting sleeve 27 is fixedly connected with a pressure plate 3, and the pressure plate 3 and the mounting sleeve 27 are inclined at 30°. The effect of the cylinder 2 is used to make the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com