Investment casting mold shell firing device for plow making

An investment casting and mold shell technology, which is applied in the field of investment casting mold shell firing devices for plow making, can solve the problems of low manual operation efficiency and inability to work for a long time, and achieve the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

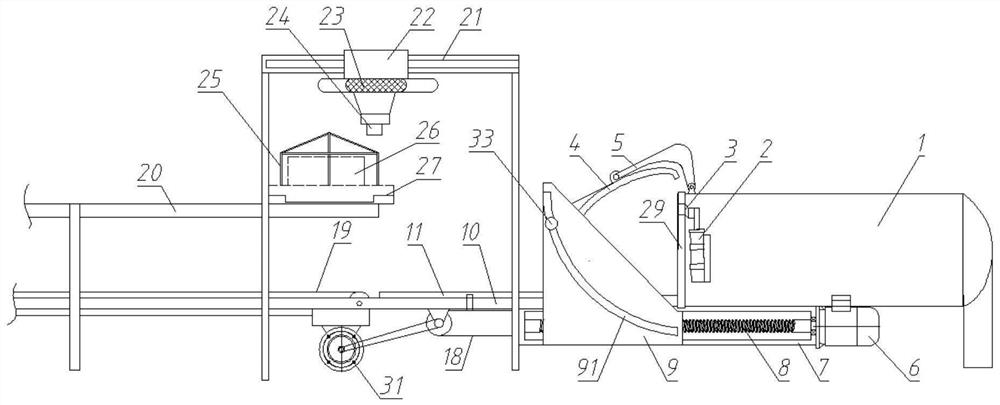

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

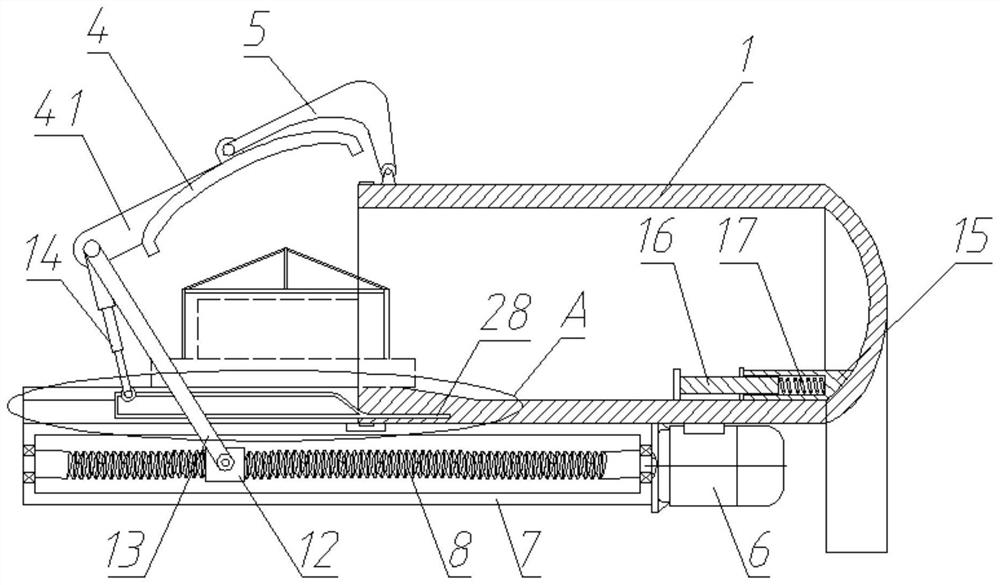

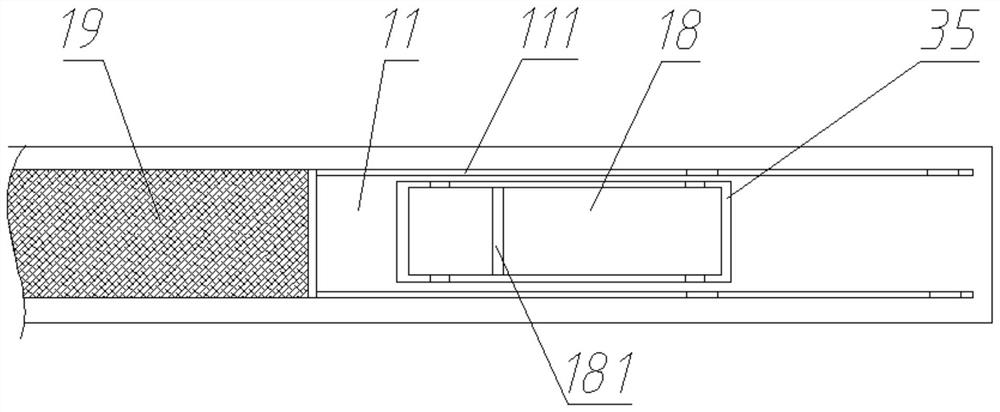

[0023] Such as Figure 1-8 Shown is an investment casting mold shell firing device for making plows, including a high-temperature furnace 1, a transport vehicle and a wax pattern transmission device. The transport vehicle includes a base 27 and a bracket 25 located above the base 27. The base 27 is provided with a The pulley 34 that chute 111 cooperates;

[0024] The opening of the high temperature furnace 1 is provided with a dodge door 4, the dodge door 4 is rotatably connected with the side wall of the high temperature furnace 1 through the pivoting arm 5, and the bottom of the high temperature furnace 1 is fixed with two mounts 7 and two first motors 6, which are installed A screw rod 8 is provided in the seat 7, and the right side of the screw rod 8 is connected with the first motor 6 after passing through the mounting seat 7. The screw rod 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com