Automobile armrest framework die

A technology for automobile armrests and skeletons, which is applied in the field of automobile armrest skeleton molds, which can solve the problems of large horizontal mold space and achieve the effects of reducing floor space, improving space utilization, and low space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The following is attachedFigure 1-16Give further details on this application.

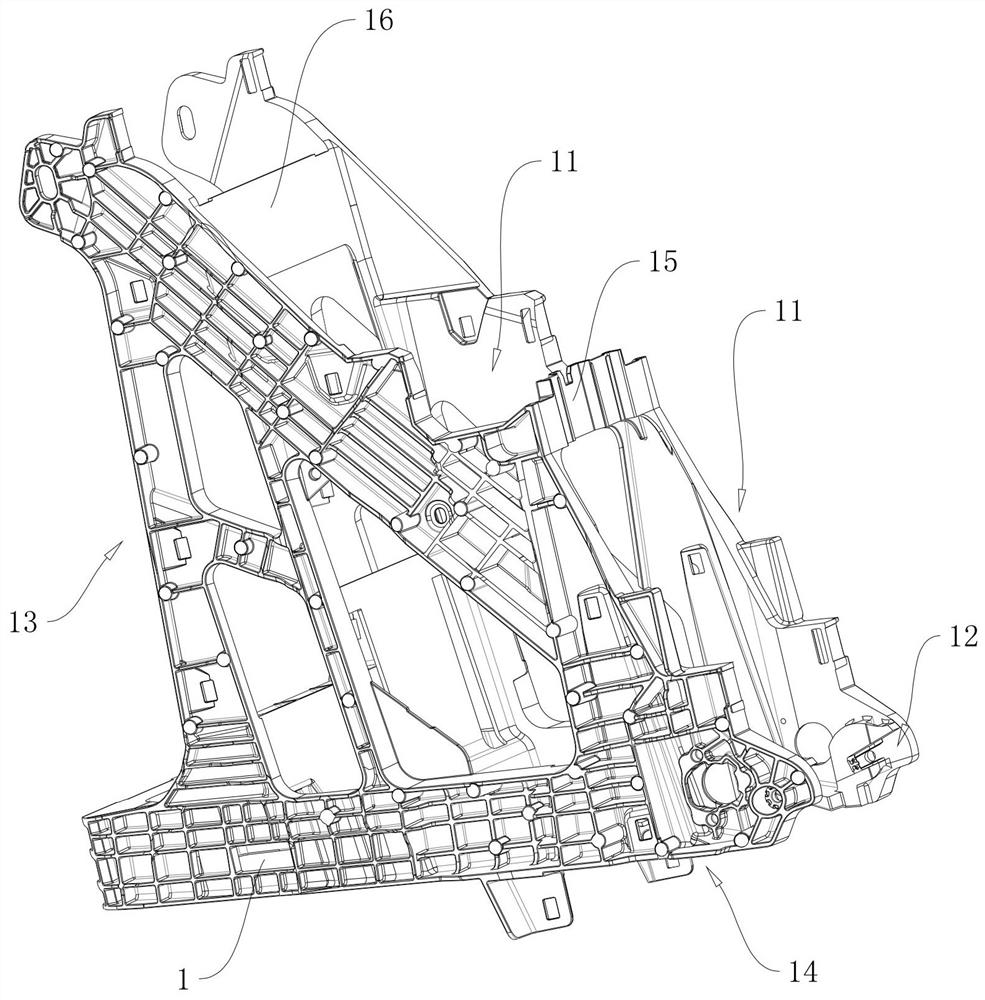

[0051]The embodiment of the application discloses an automobile armrest skeleton mold. Refer tofigure 1 , The automobile armrest frame 1 is in the shape of a hollow frame as a whole, and a large number of open spaces are formed staggered inside, including a first core-pulling space 11, a second core-pulling space 12, a third core-pulling space 13 and a fourth core-pulling space 14. A core-pulling space 11 is divided into two parts by a first partition bar 15, the first partition bar 15 is a part of the skeleton, and a second partition bar 16 is provided between the third core-pulling space 13 and the first core-pulling space 11 , The second divider 16 is also a part of the skeleton.

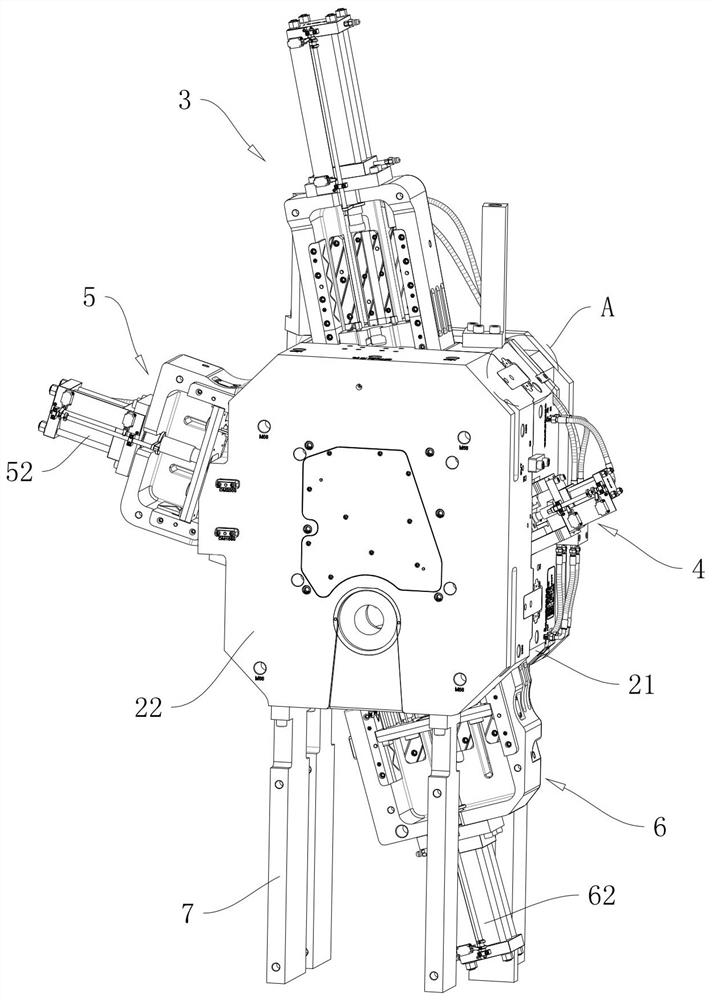

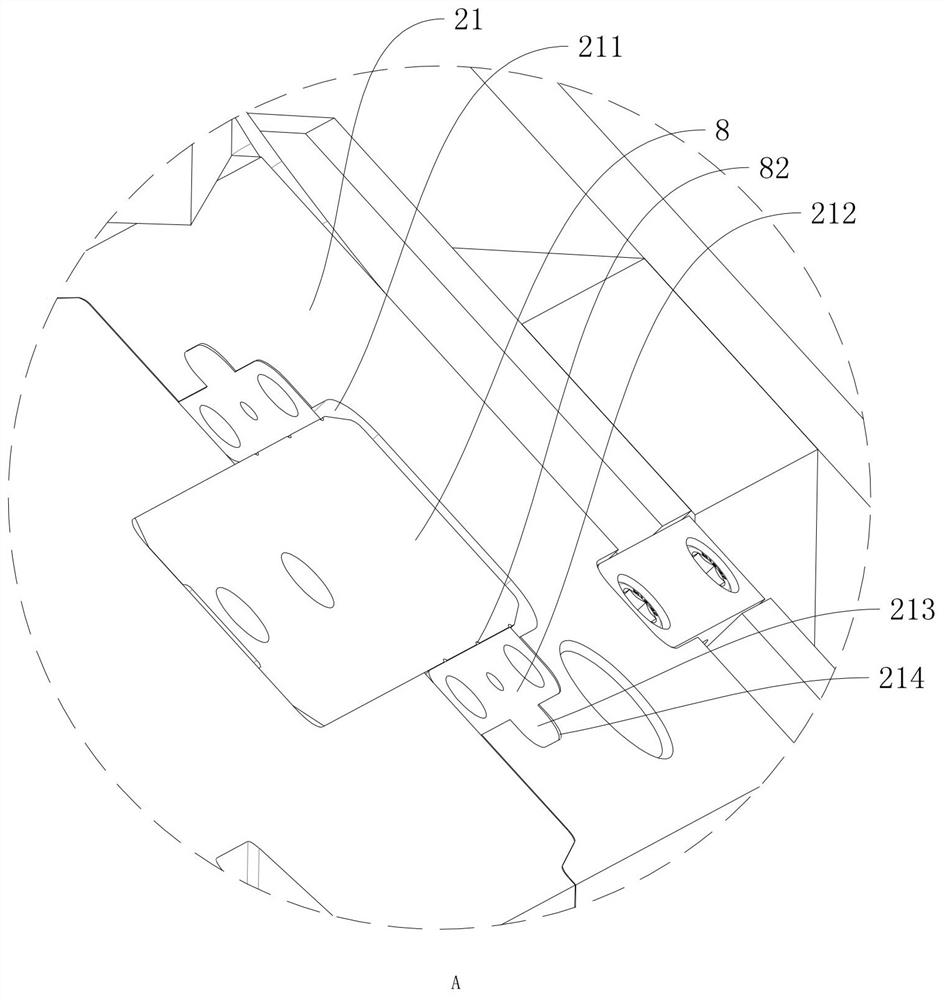

[0052]Refer tofigure 2 , Auto armrest skeleton mold, including a mold base, a first core-pulling component 3, a second core-pulling component 4, a third core-pulling component 5 and a fourth core-pulling component 6, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com