Automatic disassembling and assembling system for container lockset

A technology for automatic disassembly and assembly of containers, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of high labor costs, hidden dangers to personal safety, labor-intensive and other problems, achieve a reasonable and compact overall layout, maximize the operation area, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

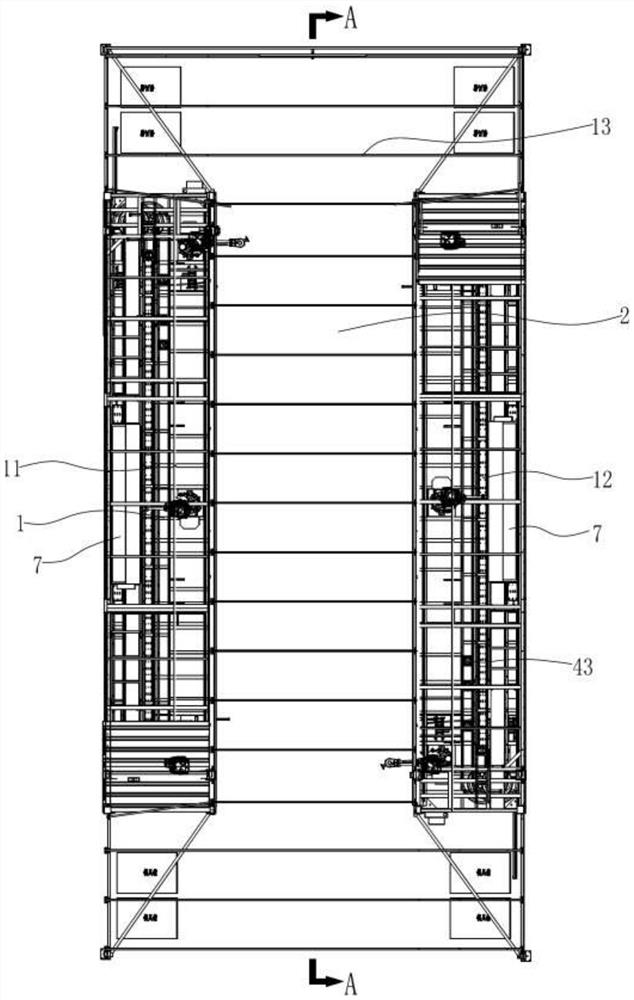

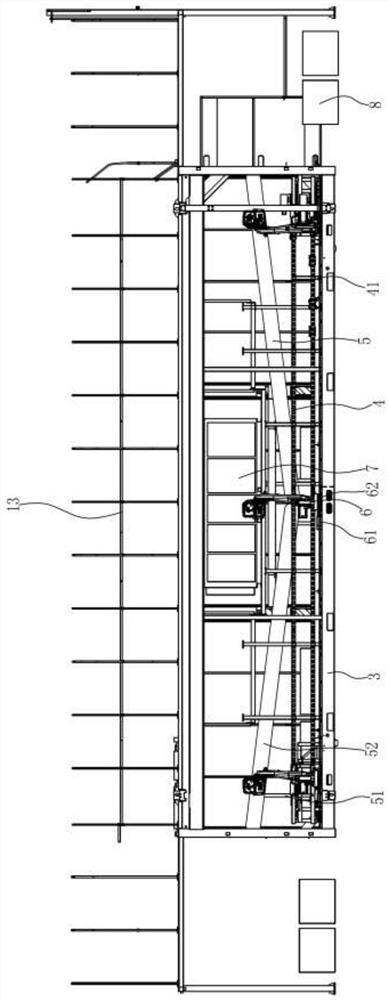

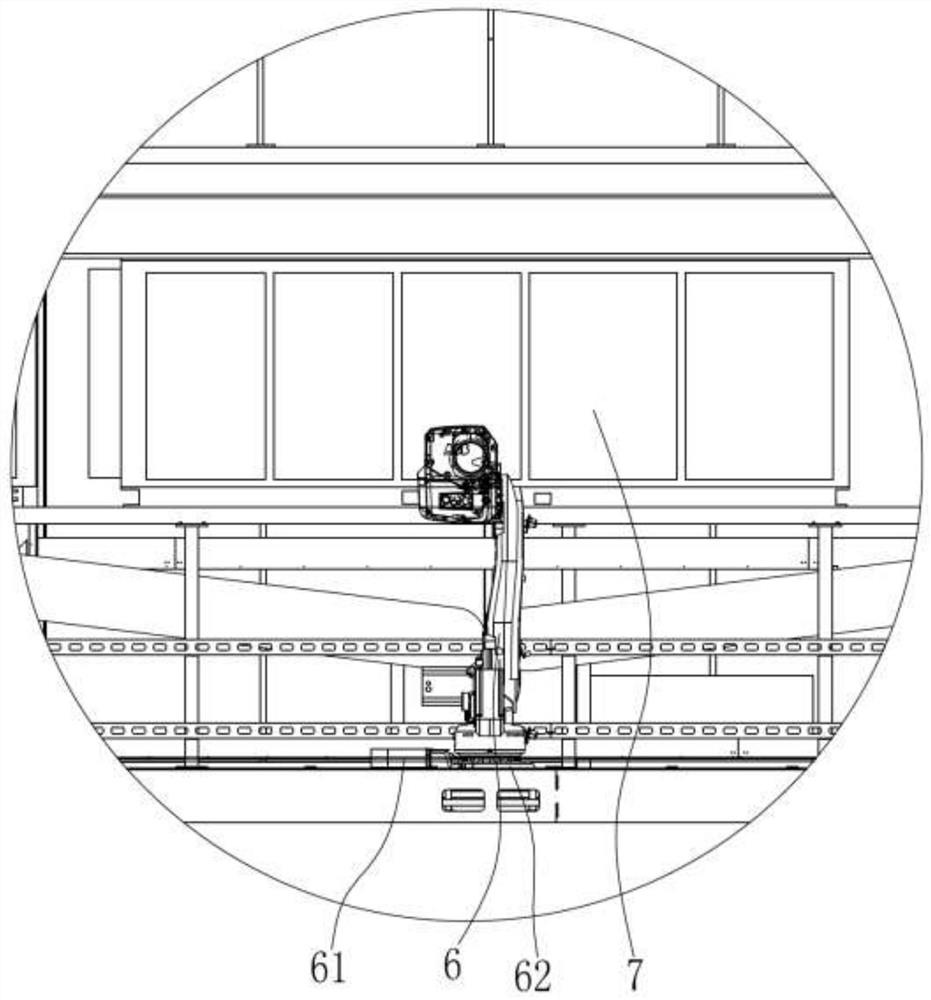

[0049] Such as Figure 1 to Figure 11 As shown, an automatic disassembly and assembly system for container locks includes two side disassembly and assembly groups 1 arranged in parallel, which automatically disassemble and install locks on both sides of the container respectively. The container channel 2 of the container, the container channel 2 can also be passed by the container truck, the side disassembly group 1 includes a support platform 3 at the bottom for supporting equipment, and a support platform 3 fixed on the support platform 3 for transporting the equipment to be transported. The first lock delivery device 4 for installing locks, the transmission and recovery device 5 for transporting removed locks, the lock model identification device, the first automatic disassembly and assembly manipulator 6 and the PLC control cabinet 7, a plurality of first automatic disassembly and assembly manipulators 6 Intervals are arranged on the side of the first lock conveying device...

Embodiment 2

[0065] One or more rows of middle dismantling groups 9 are arranged between the two side dismantling groups 1, and the channel is correspondingly widened. Device 91, the second automatic disassembly manipulator 92, a plurality of second automatic disassembly manipulators 92 are arranged on the inner side of the second lock delivery device 91, that is, the second automatic disassembly manipulator 92 both sides have locks that are transported in a circular manner, and the locks on both sides Containers are all within the operating range of the second automatic dismounting manipulator 92, so that two passages, three passages, and even N passages can be operated at the same time, so that the wharf with a large workload can also maintain a higher efficiency of locking and dismantling.

[0066] In this embodiment, there are four second automatic disassembly and assembly manipulators 92 in total, and the middle two second automatic disassembly and assembly manipulators 92 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com