Stable thatch-top concrete wood-like building roof and cornice construction method thereof

A technology of concrete and fine stone concrete, which is applied in the field of imitation wood buildings, can solve the problems of thatch-roof concrete imitation wood building roof and cornice deformation, shedding of building materials, and reduced service life, achieving good fire resistance and strong deformation resistance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

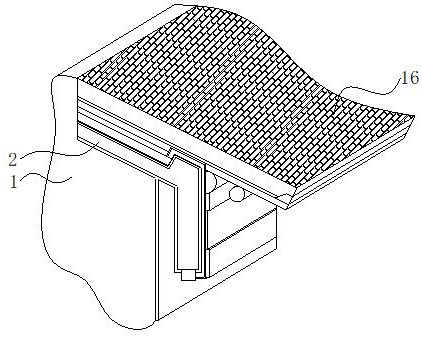

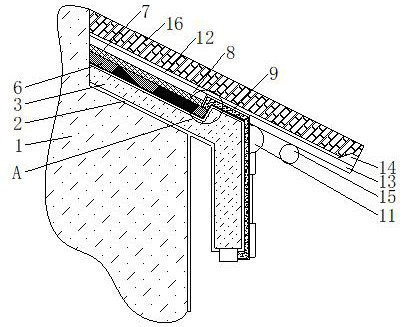

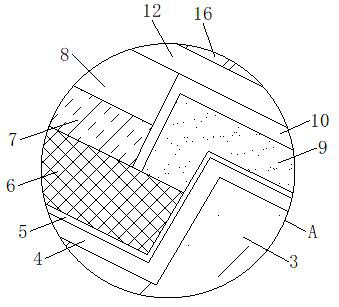

[0025]In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified, and are described in detail below with accompanying drawings.

[0026]The structure of the present invention will be described in detail below in conjunction with the drawings.

[0027]Such asFigure 1 to Figure 3As shown, the embodiment of the present invention provides a concrete wood-like building roof with a thatch roof with good stability, comprising a wall body 1, the top of the wall body 1 is fixedly connected with a board bottom 2, and the top of the board bottom 2 is fixedly connected with a panel 3 , The top of the panel 3 is fixedly connected with a leveling layer 4, the top of the leveling layer 4 is fixedly connected with a first waterproof layer 5, and the top of the first waterproof layer 5 is fixedly connected with an extruded polystyrene board 6, and an extruded polystyrene board 6 The top is fixedly connected with the fine stone conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com