Heat distribution pipeline fixing support with end connected with pre-buried pore plate structure

A thermal pipeline and end connection technology, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., to reduce adverse effects, facilitate installation, and avoid vertical force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

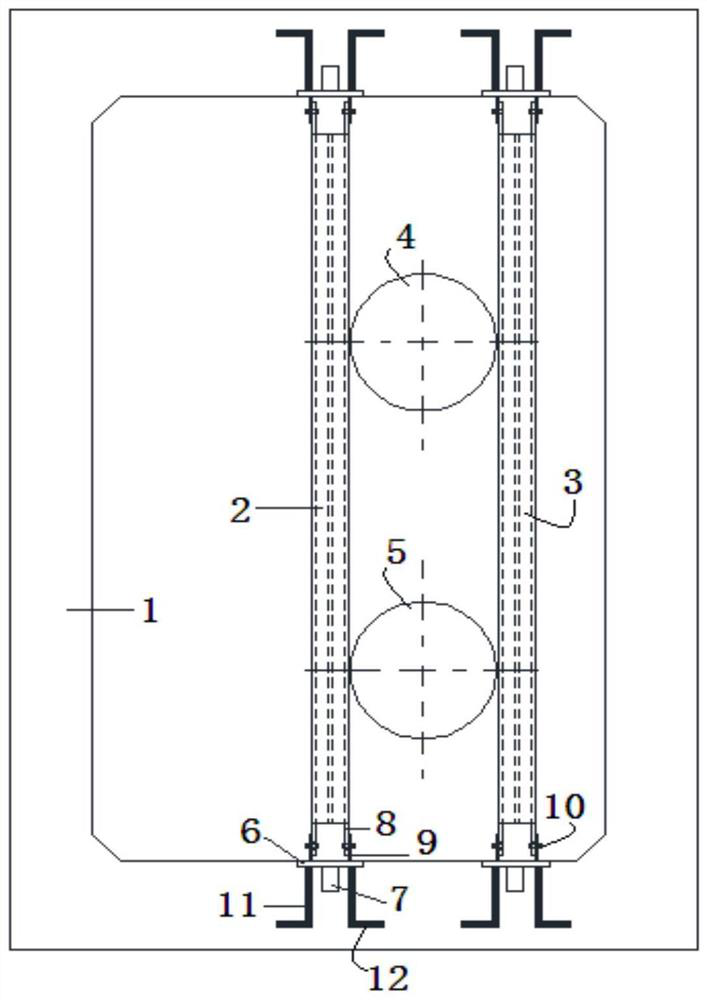

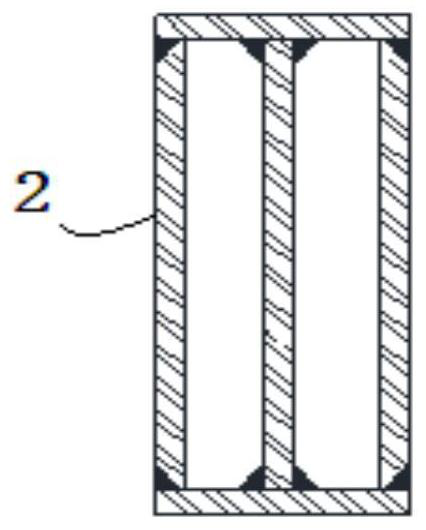

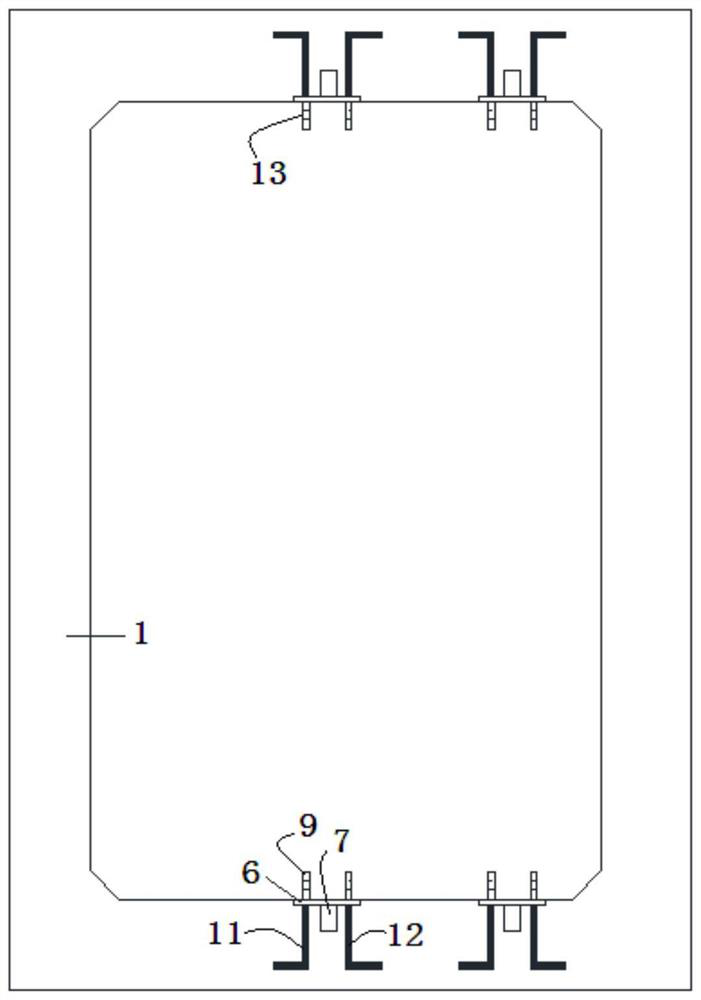

[0022] Below with the accompanying drawings ( Figure 1-Figure 5 ) to illustrate the present invention.

[0023] figure 1 It is a structural schematic diagram of a thermal pipeline fixing bracket with an end-connected embedded orifice plate structure implemented in the present invention. figure 2 figure 1 Schematic diagram of the cross-sectional structure of the middle left bracket column. The right support column and the left support column are support columns with the same structure. image 3 yes figure 1 Schematic diagram of the structure of the pipe gallery after the middle support column is not installed or removed. Figure 4 yes figure 1 or image 3 Schematic diagram of the embedded orifice plate structure. Figure 5 yes figure 1 Schematic diagram of the end orifice plate structure of the middle left support column 2 or the right support column 3. refer to Figure 1 to Figure 5 As shown, a thermal pipeline fixing bracket whose end is connected to a pre-buried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com