A metal surface corrosion monitoring device based on fiber grating with temperature compensation

A temperature compensation, metal surface technology, applied in the direction of measuring devices, optical devices, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as low monitoring accuracy, long monitoring execution time, and complicated monitoring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

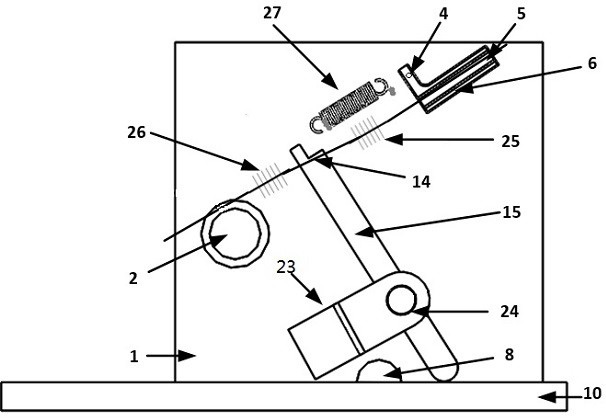

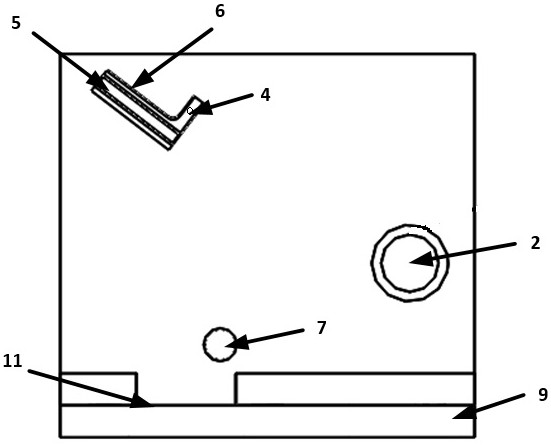

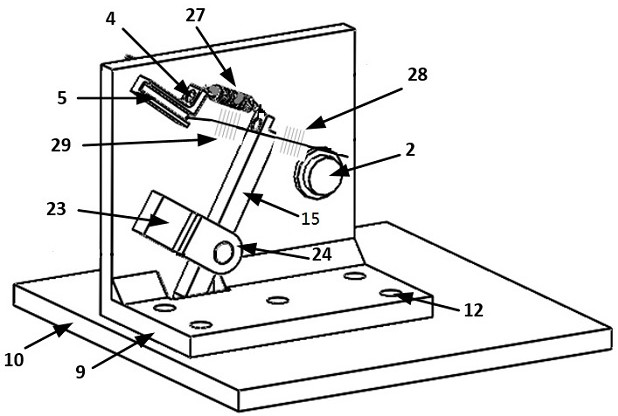

[0024] As shown in the figure, a metal surface corrosion monitoring device based on fiber grating with temperature compensation includes: L-shaped base 1, four fiber Bragg grating sensors, two test rods and two buckles 23, two pull Spring 27, L-shaped base 1 overcoat has protective cover.

[0025] The two side walls of the L-shaped base 1 are symmetrically distributed with a two-section stepped cylinder 2, a circular groove 7 and an L-shaped convex body block 6 with a circular hole 13 and a groove 5. The two sides are different. The difference is that there is a semicircular cylinder 8 on the outer side of the L-shaped base 1, and a rectangular groove 11 through the base plate is opened on the bottom plate 9 close to the inner side wall of the L-shaped base, and the test rod 20 on the inner side of the L-shaped base 1 extends Into the rectangular groove 11, there are five fixing holes 12 on the base plate 9, and the L-shaped base 1 is affixed to the metal plate 10 to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com