Double-branch cable for electronic blasting system, manufacturing process thereof, and mold

A manufacturing process and electronic technology, applied in cable/conductor manufacturing, insulated cables, cleaning methods and utensils, etc., can solve the problem that cables cannot meet construction conditions, meet construction environment and conditions, improve strength, and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

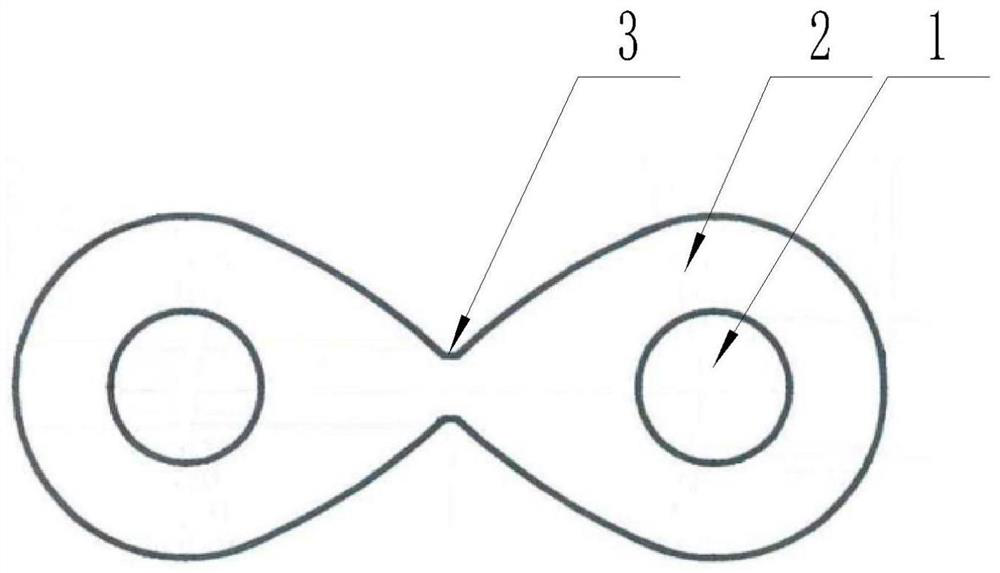

[0052] A dual-branch cable for an electronic blasting system, wherein, such as figure 1 As shown, it includes: a conductor 1, an insulating part 2, and a connected part 3. The conductor 1 is made of an alloy material, and there are at least two conductors 1 arranged horizontally with a certain gap between the conductors 1 .

[0053] The conjoined part 3 and the insulating part 2 are injection molded into one or one-piece structure. The insulating part 2 is attached to the conductor 1. The insulating part 2 and the conjoined part 3 are made of wear-resistant materials. 2, and the connected part 3 forms a connected double-parallel structure with the insulating part 2 and the two conductors 1.

[0054] Specifically, the insulating part 2 and the connected part 3 are attached to the conductor 1 by a high-pressure extrusion process to form a vertical water-blocking connected double structure.

[0055] The present invention uses a high-strength alloy conductor 1 on the premise of ...

Embodiment 2

[0067] A mold, wherein the mold includes a mold cavity, and the mold cavity is a conjoined double parallel structure.

Embodiment 3

[0069] A double-branch cable manufacturing process for the electronic blasting system for manufacturing the double-branch cable of the electronic blasting system described in the first embodiment, which has the mold described in the second embodiment, and includes the following steps:

[0070] The conductor 1 is selected, and the conductor 1 made of two alloy materials is selected;

[0071] The surface is clean, and the two conductors 1 are laid out in parallel. After the impurities and oil on the surface of the conductor 1 are removed by high temperature, they are then wiped with a dust-removing cloth to ensure that the conductor 1 is clean and improve the insulation adhesion;

[0072] Extrusion molding, put the wear-resistant material into the mold, melt the wear-resistant material through the extrusion temperature of 180 ° C ~ 225 ° C, and extrude the wear-resistant material out of the mold, the pressure during extrusion will be between the conductor 1 and the insulation Fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com