Automatic feeding type sheet metal machining equipment

A technology of automatic feeding and processing equipment, applied in the field of sheet metal processing, can solve the problems of low degree of automation, slow feeding efficiency, hidden safety hazards, etc., and achieve the effect of good feeding effect, easy replacement and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

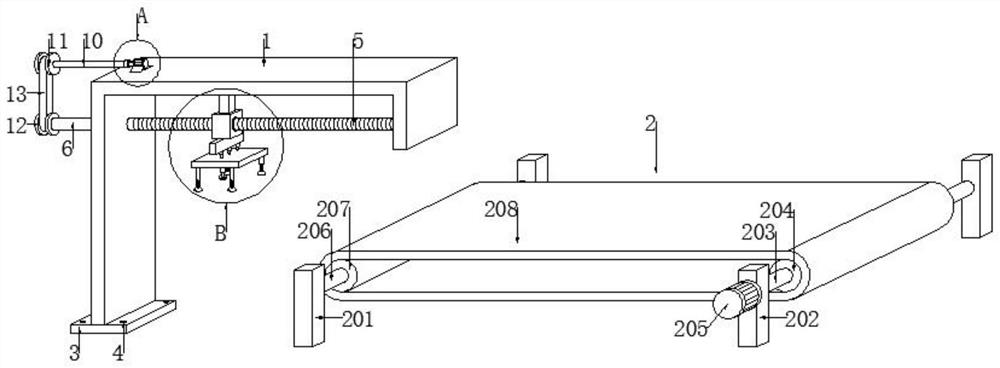

[0034] see Figure 1-5 , an automatic feeding sheet metal processing equipment, including a fixed seat 1 and a transmission device 2, the lower end of the fixed seat 1 is fixedly connected with a mounting seat 3, the mounting seat 3 plays the role of installation, and the four corners of the upper end of the mounting seat 3 are provided with There are mounting screw holes 4 and 4, which are convenient for us to use strong mounting screws to install with the ground, so as to fix the fixing base 1 and make it more stable;

[0035] The transmission device 2 includes a first support column 201, a second support column 202, a driving shaft 203, a driving roller 204, a common motor 205, a driven shaft 206, a driven roller 207 and a driven roller 208, the first support column 201 and the second Two support columns 202 are provided with a pair, and the second support column 202 is located on the right side of the first support column 201, a pair of first support columns 201 and a pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com