Automobile energy-absorbing box and secondary forming process and device thereof

A technology of secondary molding and energy-absorbing box, which is applied to other household appliances, bumpers, household components, etc., can solve the problems of single-time energy-absorbing effect, inability to absorb impact force, affecting production efficiency, etc., so as to improve production efficiency and improve production efficiency. The effect of production stability and reduction of cutting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

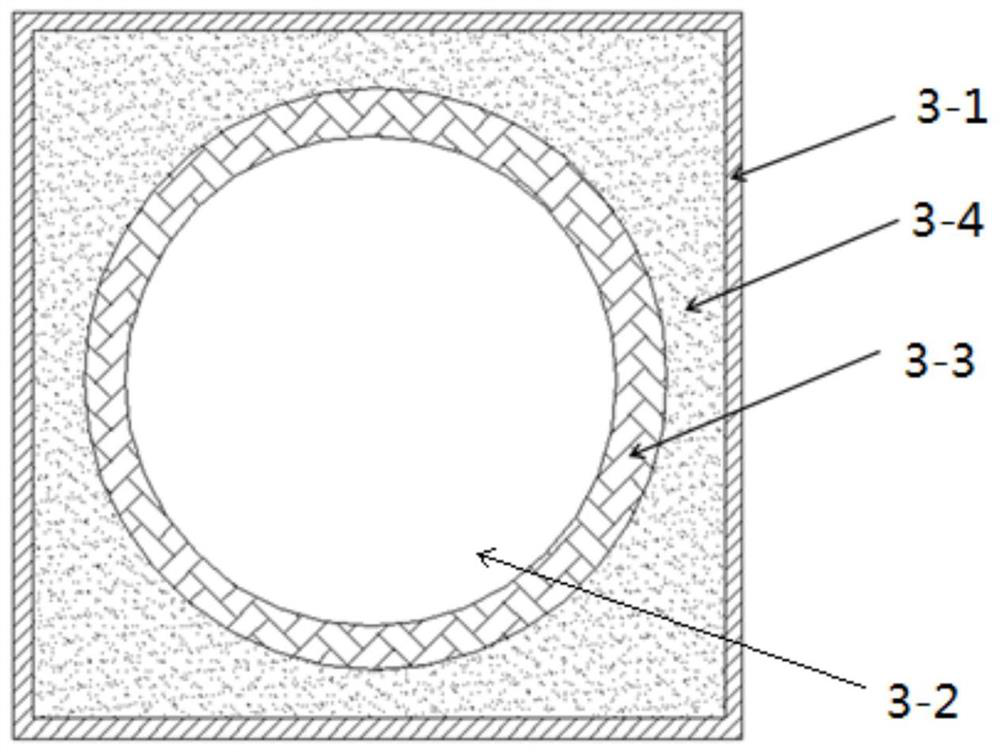

[0051] Such as figure 1 As shown, the present invention provides an automobile energy-absorbing box, which sequentially includes a first-level energy-absorbing structure and a second-level energy-absorbing structure from the outside to the inside, wherein the first energy-absorbing metal foam structure includes an elastic recovery force an elastic body 3-1, and an elastic material 3-4 disposed inside the elastic body 3-1;

[0052] The second energy-absorbing elastic structure includes a soft plastic ball 3-2, and a carbon fiber prepreg 3-3 fully wrapped on the outer surface of the soft plastic ball 3-2, and the soft plastic ball 3-2 and the carbon fiber prepreg 3-3 together To form a carbon fiber liner, the elastic material 3-4 completely surrounds the outer surface of the carbon fiber prepreg 3-3.

[0053] The automobile energy-absorbing box provided in this embodiment includes three parts: a metal shell, an elastic material and a carbon fiber liner. Performance thermoplast...

Embodiment 2

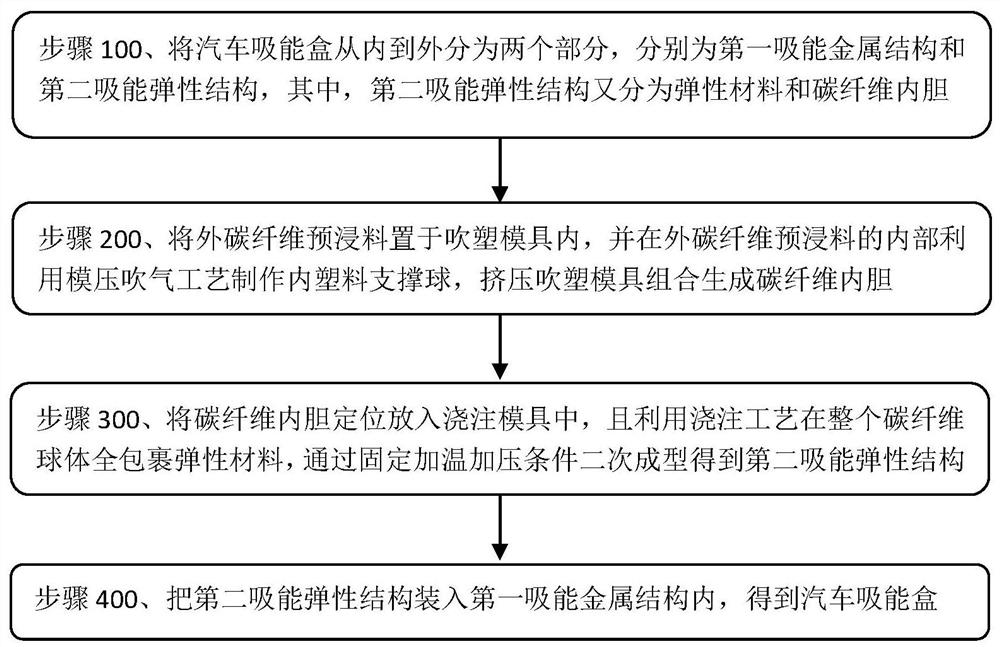

[0056] In addition if figure 2 As shown, the present invention also provides a secondary molding process for an automobile crash box, comprising the following steps:

[0057] Step 100: Divide the automobile energy-absorbing box into two parts from the inside to the outside, which are the first energy-absorbing metal foam structure and the second energy-absorbing elastic structure, wherein the second energy-absorbing elastic structure is specifically a carbon fiber liner, The first energy-absorbing metal foam structure includes a metal elastic shell, and an elastic material arranged in the metal elastic shell and wrapped outside the carbon fiber liner;

[0058] Step 200: Divide the carbon fiber liner into an outer carbon fiber prepreg and an inner foam support ball, place the outer carbon fiber prepreg in a blow mold, and make an inner hair inside the outer carbon fiber prepreg using a molding blowing process Foam support ball, extrusion blow molding mold combined to generate...

Embodiment 3

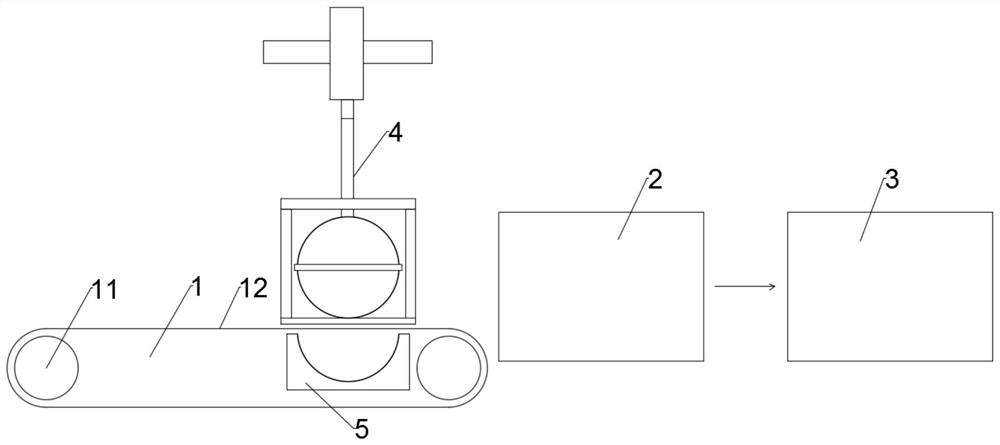

[0074] Such as image 3 As shown, the present invention also provides a secondary molding device for automobile crash boxes, including a carbon fiber delivery unit 1, a primary blow molding unit 2 and a secondary casting molding unit 3, the carbon fiber delivery unit 1 and the primary blow molding unit There is a carbon fiber cutting unit 4 between the 2. The carbon fiber cutting unit 4 cuts the outer carbon fiber prepreg according to the fixed interval time and interval length and generates an energy-absorbing ball prefabricated body with the same surface area as half a ball of the carbon fiber inner tank. The carbon fiber delivery unit 1 Continuously transport the energy-absorbing ball prefabricated body to the primary blow molding unit 2 and form a carbon fiber inner container together with the plastic parison.

[0075] After the carbon fiber liner is cured at high temperature, it is positioned and placed in the secondary pouring molding unit 3. The secondary pouring moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com