Centrifugal equipment for sea water desalination

A technology of centrifugal equipment and inner drum, which is used in seawater treatment, centrifugal separation of water/sewage treatment, etc., can solve the problems of ineffective separation of salt on the surface of ice crystals, reduction of fresh water production, and consumption of fresh water, so as to reduce the amount of melting, Reduces ice crystal buildup and increases freshwater production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

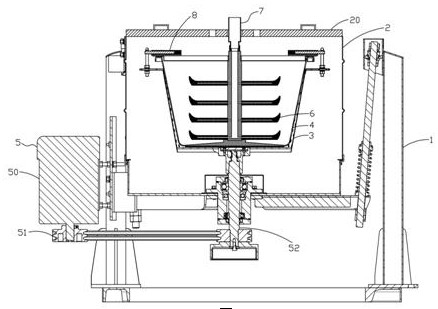

[0054] In the traditional scheme, when the ice crystals are crushed to a certain size and then added to the inner drum 4 for centrifugation, if the amount of material added is too small, the efficiency will be too low; , resulting in a large amount of salt attached to the ice crystals and the salt in the gaps of the ice crystals cannot be effectively separated from the ice crystals under the action of centrifugation, which will significantly deteriorate the desalination effect. In this embodiment, by setting the ice crystal dispersing mechanism 6, the ice crystals added to the inner drum 4 can be effectively dispersed to reduce the accumulation of ice crystals and the phenomenon of mutual adhesion, and promote the separation of salt and ice crystals; further, by purging Mechanism 7 provides high-pressure gas to purge the ice crystals, so that the salt adhered to the ice crystals can be separated from the ice crystals smoothly, and the salt in the gap between the ice crystals ca...

Embodiment 2

[0076] refer to Figure 9-10 The locking assembly 8 includes a locking seat 80 affixed to the sealing cover 43, a sliding sleeve 81 affixed to the locking seat 80, a locking pin 82 movably inserted in the sliding sleeve 81, and a vertically connected On the locking pin 82 and out of the driving rod 83 of the sliding sleeve 81, the chute 84 provided on the sliding sleeve 81 in the axial direction for the sliding of the driving rod 83 and connected between the inner end of the driving rod 83 and the sliding sleeve 81 The compression spring 85;

[0077] A U-shaped bolt 30 is arranged on the outer drum 3 , and the outer end of the driving rod 83 can be inserted into the U-shaped bolt 30 so as to realize the locking between the sealing cover 43 and the outer drum 3 .

[0078]The working principle of the locking assembly 8 is: the compression spring 85 produces an outward thrust on the locking pin 82, so that the locking pin 82 will slide outwards to the limit position relative to ...

Embodiment 3

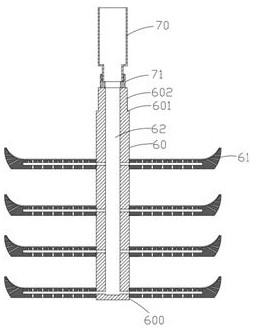

[0080] refer to Figure 11 The outer wall of the mounting post 60 is also provided with some second jet holes 68 communicating with the air passage 62, the second jet holes 68 are tapered, and the diameter of the gas outlet of the second jet holes 68 is smaller than the diameter of the air inlet. The setting of the second jet hole 68 can further improve the blowing effect on the ice crystals, which is beneficial to the separation of salt and ice crystals.

[0081] In one embodiment, the working process of the centrifugal device for seawater desalination is:

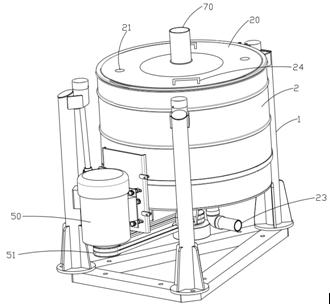

[0082] 1. Add ice crystals: the external pipeline for supplying compressed air is removed from the air inlet pipe 70, and the outer protective cover 20 is opened by rotating the handle 24, and the air inlet pipe 70 is removed from the rotary joint 71 (or not removed) , open the locking assembly 8, then rotate the sealing cover 43, so that the sealing cover 43 is separated from the mounting column 60 to open, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com