Cooling sewage recycling system

A technology of recycling and cooling water, applied in the field of water circulation, can solve problems such as less polluting components, hidden dangers in the production of metal debris workshops, and affect the normal operation of equipment, and achieve the effect of improving utilization and simple adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The sewage obtained by cooling the mechanical equipment with the cooling water nozzle, its main components are equipment oil and dust particles;

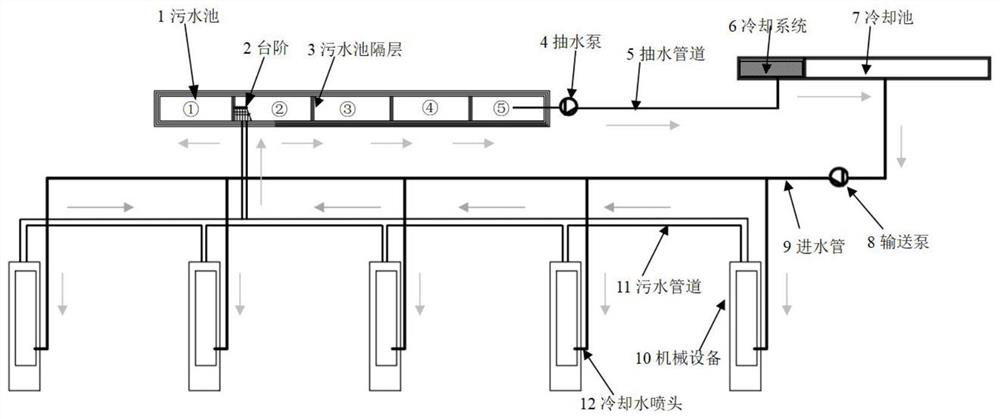

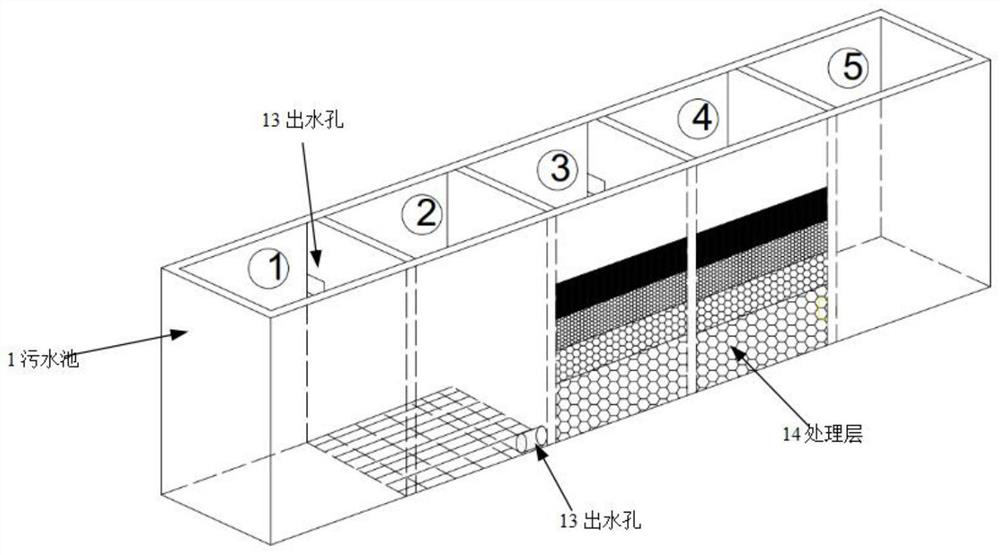

[0023] Such as figure 1 As shown, a cooling sewage recycling system mainly includes a sewage pipeline 11 , a sewage tank 1 , a pumping pipeline 5 , a cooling pool 7 , a water inlet pipe 9 , a cooling water nozzle 12 and mechanical equipment 10 . Sewage pipeline 11 is connected with sewage treatment grid 2., and step 2 is provided in the sewage pool treatment grid 2. It is mainly convenient to the maintenance of 2. bottom outlet hole 13 iron drums of sewage treatment grid.

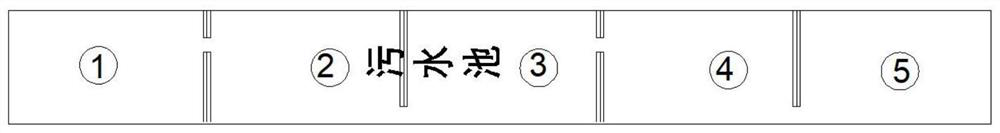

[0024] Such as figure 1 As shown, the sequence of sewage flow is ①←②→③→④→⑤; the purpose of the sewage treatment grid ① is to collect surface oil floating in the cooling sewage, and the treatment layer 14 adsorbs oil and dust particles, and the treatment Layers can be replaced every 2-3 months.

[0025] Such as figure 2 As shown, the sewage pool 1 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com