Hydrofluoric acid etching solution for etching gallium indium zinc oxide film and application thereof

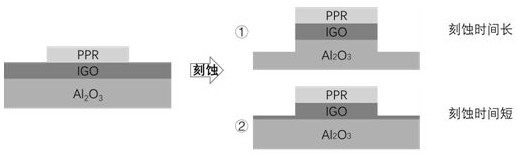

A technology of gallium indium zinc oxide and hydrofluoric acid, applied in the direction of surface etching compositions, chemical instruments and methods, electrical components, etc., can solve the problem of large loss of the lower tunneling layer, unstable properties of the etching solution, and uncontrollable etching speed etc. to achieve the effect of slow etching speed, stable etching process and controllable etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Select a heavily doped p-type silicon wafer as the substrate, and use magnetron sputtering equipment to deposit 10nm aluminum oxide (Al 2 o 3 ), and then in Ar atmosphere, magnetron sputtering deposited 15nm gallium indium zinc oxide (IGZO) film with a mass ratio of 1:1:1, and the radio frequency power was 70W, which was used as the experimental material;

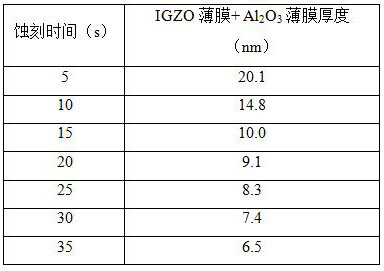

[0024] (2) Dilute the concentrated hydrofluoric acid solution with a concentration of 40% plus deionized water to 100 times, and then immerse the multiple experimental materials prepared in step (1) in the diluted hydrofluoric acid solution at 25°C, respectively Last for 5 seconds, 10 seconds, 15 seconds, 20 seconds, 25 seconds, 30 seconds and 35 seconds, take it out, rinse it with deionized water and dry it, and measure the thickness of alumina with an ellipsometer. The results are shown in Table 1 Show.

[0025] Table 1 shows the residual thickness of the aluminum oxide layer under different etching times. It...

Embodiment 2

[0030] (1) Select a heavily doped p-type silicon wafer as the substrate, and use magnetron sputtering equipment to deposit 10nm aluminum oxide (Al 2 o 3 ), and then in Ar atmosphere, magnetron sputtering deposited 15nm gallium indium zinc oxide (IGZO) film with a mass ratio of 1:1:1, and the radio frequency power was 70W, which was used as the experimental material;

[0031] (2) Dilute the concentrated solution of hydrofluoric acid with a concentration of 20% plus deionized water to 100 times, and then immerse the multiple experimental materials prepared in step (1) in the diluted solution of hydrofluoric acid at 25°C, respectively Last for 8 seconds, 16 seconds, 24 seconds, 32 seconds, 40 seconds, 48 seconds, 56 seconds, take it out, rinse it with deionized water and dry it, then use an ellipsometer to measure the thickness of alumina, the results are shown in Table 2 Show.

[0032] Table 2 shows the residual thickness of the aluminum oxide layer under different etching t...

Embodiment 3

[0037] (1) Select a heavily doped p-type silicon wafer as the substrate, and use magnetron sputtering equipment to deposit 10nm aluminum oxide (Al 2 o 3 ), and then in Ar atmosphere, magnetron sputtering deposited 15nm gallium indium zinc oxide (IGZO) film with a mass ratio of 1:1:1, and the radio frequency power was 70W, which was used as the experimental material;

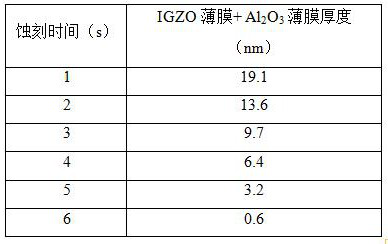

[0038] (2) Dilute the concentrated hydrofluoric acid solution with a concentration of 10% plus deionized water to 10 times, and then immerse the multiple experimental materials prepared in step (1) in the diluted solution of hydrofluoric acid at 25°C, respectively Last for 1 second, 2 seconds, 3 seconds, 4 seconds, 5 seconds, 6 seconds, take it out, rinse it with deionized water and dry it, then use an ellipsometer to measure the thickness of alumina. The results are shown in Table 3.

[0039] Table 3 shows the residual thickness of the aluminum oxide layer under different etching times, and the etching time of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap