Knitting method for processing single rib top by utilizing underwear machine

A technology for underwear machine and processing order, which is applied in underwear, weft knitting, application, etc., and can solve the problems of inability to process single cuff structure, double cylinder structure without double cylinder hosiery machine, and inability to process single cuff, etc. , to achieve the effect of not easy curling, high efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

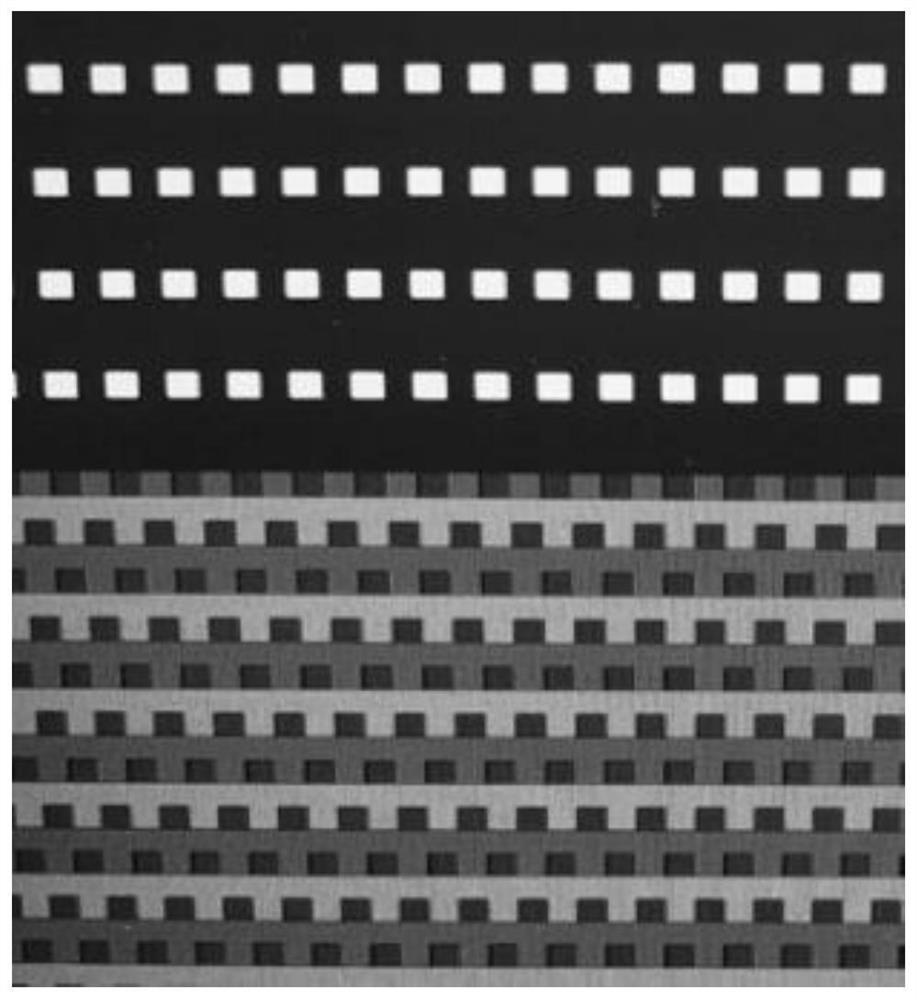

Image

Examples

Embodiment

[0024] Single cuff weave for body shaping underwear bottom boxer

[0025] Step 1: The feeder (feeder) reverses 80 stitches in the first round to tighten the tension of the elastic slightly. To achieve the effect of flat, smooth, not tight mouth and no curling when the thread structure of the foot mouth starts.

[0026] The eight-way yarn feeder in this circle does not participate in knitting and has no organizational structure, and the needle does not come out.

[0027] (1st cycle).

[0028] The second step: the second round, the 1st road at the liner position, the 1# elastic yarn feeder of the fifth road enters weaving (140D elastic yarn). The corresponding stitch structure is 1x1 rib. The other six-way yarn feeders do not move, and the needle does not come out.

[0029] (2-4 laps).

[0030] The third step: the fifth lap On the premise that the second step remains unchanged,

[0031] The 2# yarn feeder of the second road and the 2# yarn feeder of the sixth road in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com