AUV composite material propeller layering optimization design method adopting KDGO algorithm

A composite material, optimization design technology, applied in the field of objective function, can solve problems such as lack of designability, and achieve the effect of saving time, rapid forecasting, and increasing modal frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

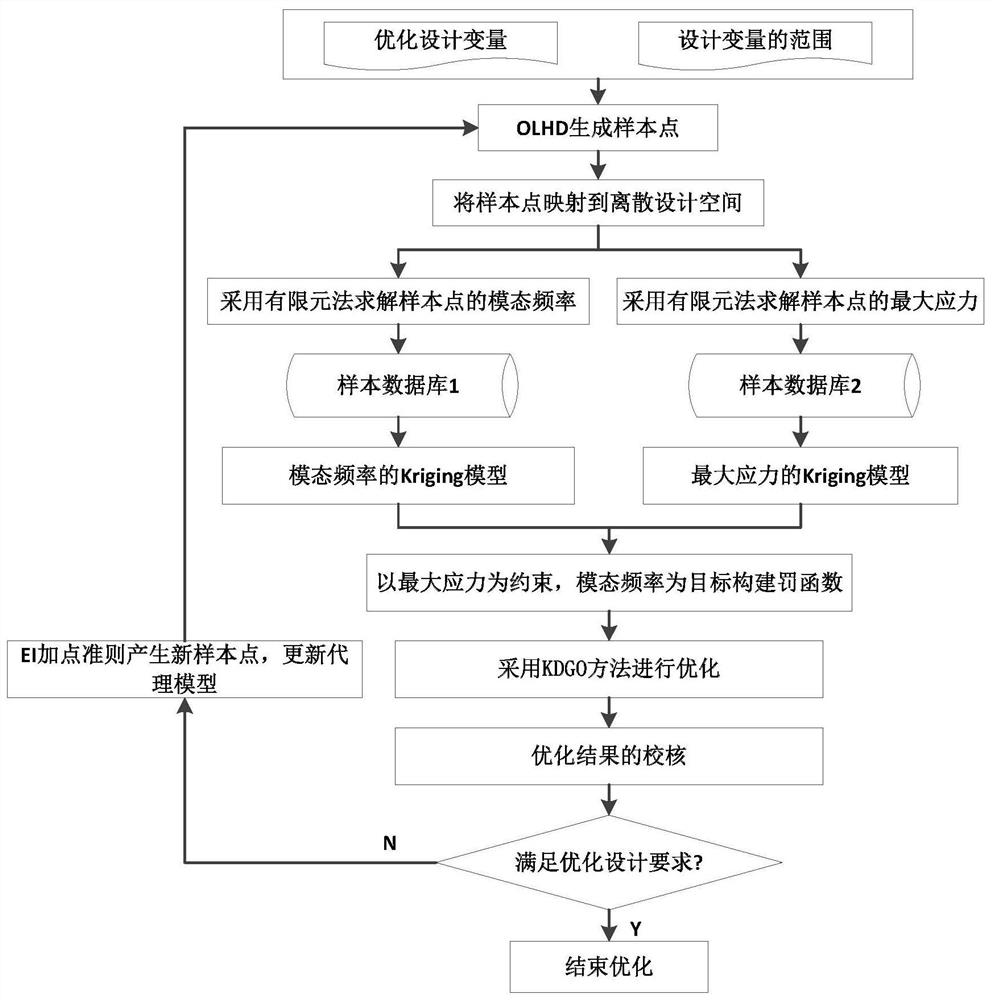

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0033] Using KDGO algorithm to optimize the design of AUV composite propeller layup is a new optimization design method, and its design variable is the angle sequence of composite propeller layup.

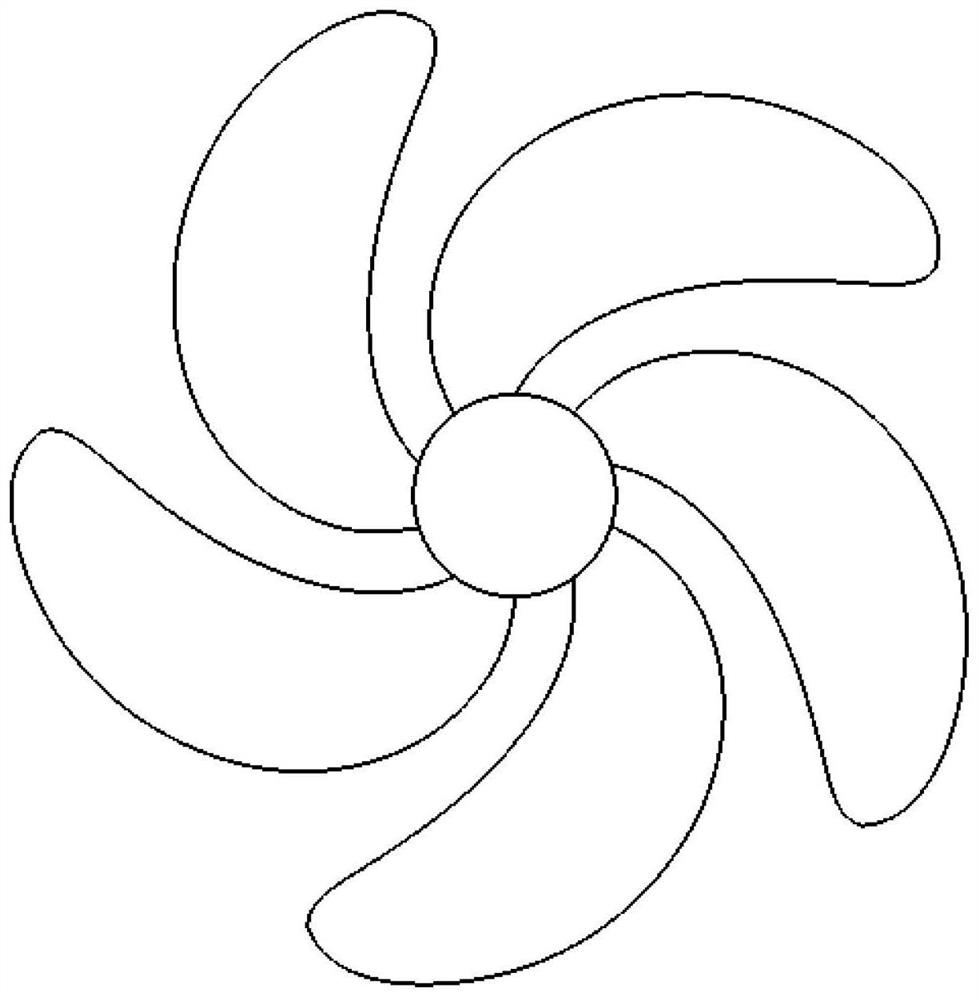

[0034] The example is based on the DTMB4383 propeller, and its geometric parameters are: the number of blades is 5, the hub diameter ratio is 0.2, the disk surface ratio is 0.725, the blade section line shape is NACA a=0.8, the blade section thickness distribution is NACA 66 (modified), and the design advance coefficient is 0.889.

[0035] Specific steps are as follows:

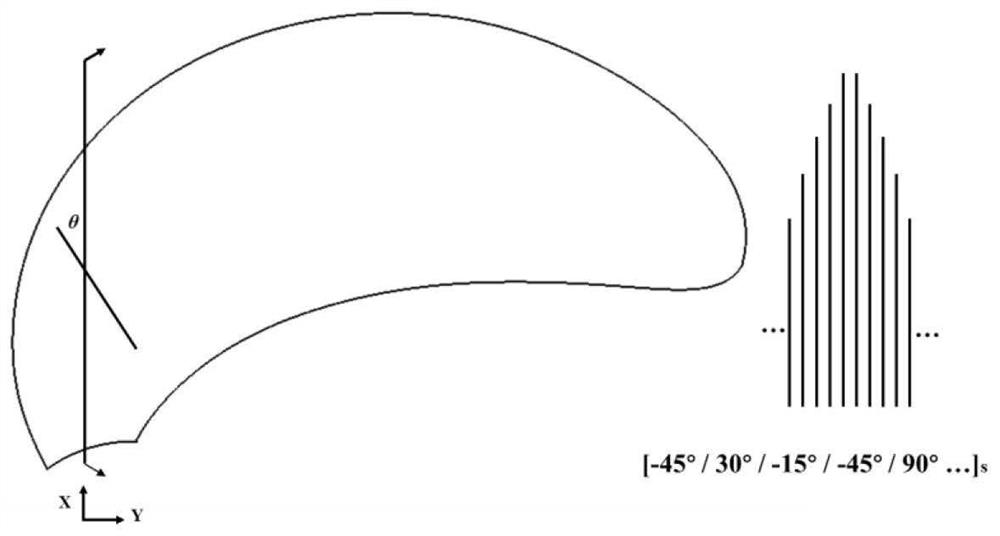

[0036] Step 1: Select Epoxy Carbon UD (395GPa) Prepreg composite material as the layup material, and the layup thickness is 0.2mm. Since the DTMB4383 propeller has a large side slope angle and the geometry of the blade is relatively complex, the middle surface of the propeller is adopted. Starting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com