Sugar gel 3D printing soft material and preparation method thereof

A 3D printing and soft material technology, applied in confectionery, confectionary industry, and oil-containing food ingredients, etc., can solve the problems that restrict the inheritance and development of Chinese sugar painting, poor processability, high cost, etc., and achieve high printing accuracy and molding The effect of good stability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

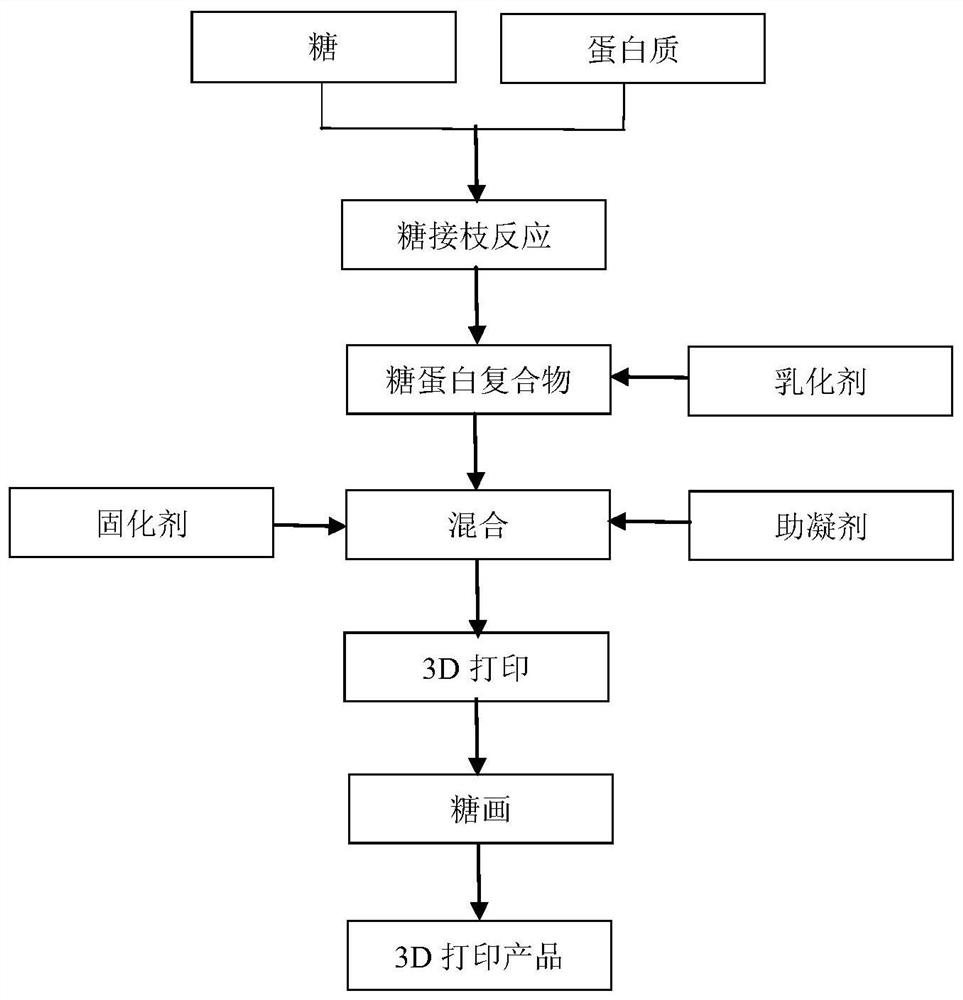

[0033] A preparation method for sugar gel 3D printing soft material, comprising the steps of:

[0034] 1) Preparation of glycoprotein complex: sugar grafting reaction of protein and sugar by ultrasound-assisted method;

[0035] In order to effectively strengthen the functional properties of proteins, improve the rheological properties of sugar gel soft materials, and improve the grafting efficiency of sugar and protein, the sugar and protein were ultrasonically treated by ultrasonic-assisted method, and the glycoprotein after ultrasonic treatment was subsequently processed. It has good stability when printing.

[0036] 2) Preparation of emulsifier: dissolving polyglycerol fatty acid ester in water, heating and stirring to dissolve, forming emulsifier for later use;

[0037] 3) Preparation of curing agent: dissolving calcium gluconate in water to form a curing agent for subsequent use;

[0038] 4) Preparation of coagulant aid: mix carrageenan and cocoa butter in proportion re...

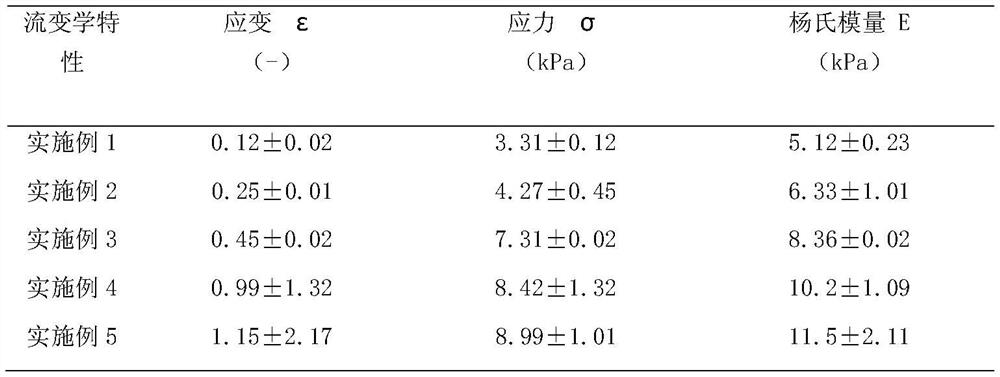

Embodiment 1

[0050] Mix protein and sugar at a mass ratio of 1:1, dissolve in PBS buffer solution with pH 7.0, stir magnetically at room temperature for 2 hours, preheat to 80°C, place the mixture in an ultrasonic device, ultrasonic power 260W, protein concentration is 10mg / mL, ultrasonic time is 15min, after the reaction is completed, it is cooled to room temperature rapidly. Dissolve polyglyceryl fatty acid ester in water, the ratio of polyglyceryl fatty acid ester to water is 1:4, the heating temperature is 70°C, and the heating time is 5 minutes to form an emulsifier for later use; slowly add calcium gluconate powder into water, gluconic acid The ratio of calcium to water is 1:1, the water temperature is 100°C, and the time is 2 minutes, and magnetic stirring is performed to form a curing agent. Slowly add an appropriate amount of carrageenan powder into dewatered water, swell at room temperature for 60 minutes, and perform magnetic stirring at 90°C until the carrageenan powder is comp...

Embodiment 2

[0052] Mix protein and sugar at a mass ratio of 1:2, dissolve in PBS buffer at pH 7.0, stir magnetically at room temperature for 2 hours, preheat to 80°C, place the mixture in an ultrasonic device, ultrasonic power 280W, protein concentration 12mg / mL ultrasonic time is 20min, after the reaction is completed, it is cooled to room temperature rapidly. Dissolve polyglyceryl fatty acid ester in water, the ratio of polyglyceryl fatty acid ester to water is 1:5, the heating temperature is 80°C, and the heating time is 7 minutes to form an emulsifier for later use; slowly add calcium gluconate powder into water, gluconic acid The ratio of calcium to water is 1:2, the water temperature is 110°C, and the time is 3 minutes, and magnetic stirring is performed to form a curing agent. Slowly add an appropriate amount of carrageenan powder into dewatered water, swell at room temperature for 80 minutes, and perform magnetic stirring at 95°C until the carrageenan powder is completely dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com