Silica gel investment casting modulation wax and preparation method thereof

A technology of investment casting and silica gel, applied in casting and molding equipment and other directions, can solve the problems of low production efficiency of artworks, insufficient artworks, poor stability, etc., and achieve the effects of low grayscale, high strength and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

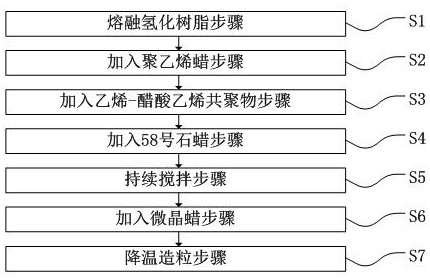

[0030] Based on the silicone investment casting modulation wax mentioned above, such as figure 1 As shown, the present invention also provides a method for preparing wax prepared by silica gel investment casting, which includes the following steps S1-S7, wherein step S5 can be omitted, and when the long-term production is expected or the follow-up process is delayed, the continuous stirring step S5 can be used to achieve continuous production work.

[0031] S1. The step of melting the hydrogenated resin, adding 1 / 2 of the hydrogenated resin to the reactor, heating and stirring fully, and then adding 1 / 2 of the remaining hydrogenated resin to continue heating and fully stirring to obtain molten hydrogenated resin. resin.

[0032] S2, the step of adding polyethylene wax, adding polyethylene wax into the reaction kettle, heating and fully stirring, so that the polyethylene wax is completely melted and mixed evenly.

[0033] S3, the step of adding ethylene-vinyl acetate copolyme...

Embodiment 1

[0048] A silica gel investment casting prepared wax, which comprises the following raw materials in parts by mass: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of montan wax, 34-36 parts of hydrogenated resin, ethylene-acetic acid Ethylene copolymer 3.5-4.5 parts, No. 58 paraffin wax 12-14 parts.

[0049] The preparation method of the above-mentioned silica gel investment casting modulated wax comprises the following steps:

[0050] (1) Divide the hydrogenated resin into two parts, heat one part at 120°C, stir continuously until it melts, then add another hydrogenated resin, continue heating, stir continuously until it melts, and obtain molten hydrogenated resin A;

[0051] (2) Continue heating the molten hydrogenated resin A obtained in step (1) at 100-120°C for 1-2 hours, add montan wax, and keep stirring until completely melted to obtain mixture B;

[0052] (3) Continue heating the mixture B obtained in step (2) at 110-120°C for 1-2 hours, add ethylene-vinyl acetate ...

Embodiment 2

[0058] A silica gel investment casting preparation wax, which comprises the following raw materials in parts by mass: 44 parts of microcrystalline wax, 2.5 parts of montan wax, 34 parts of hydrogenated resin, 3.5 parts of ethylene-vinyl acetate copolymer, and 12 parts of No. 58 paraffin wax.

[0059] The preparation method of the above-mentioned silica gel investment casting modulated wax comprises the following steps:

[0060] (1) Divide the hydrogenated resin into two parts, heat one part at 120°C, stir continuously until it melts, then add another hydrogenated resin, continue heating, stir continuously until it melts, and obtain molten hydrogenated resin A;

[0061] (2) Continue heating the molten hydrogenated resin A obtained in step (1) at 100°C for 1 hour, add montan wax, and keep stirring until completely melted to obtain mixture B;

[0062] (3) Continue heating the mixture B obtained in step (2) at 110°C for 1 hour, add ethylene-vinyl acetate copolymer, and keep stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com