Rubber and plastic product cutting device

A cutting device, a technology for rubber and plastic products, applied in metal processing and other directions, can solve problems such as difficult to cut large-scale materials, and achieve the effects of increasing bearing capacity, improving efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

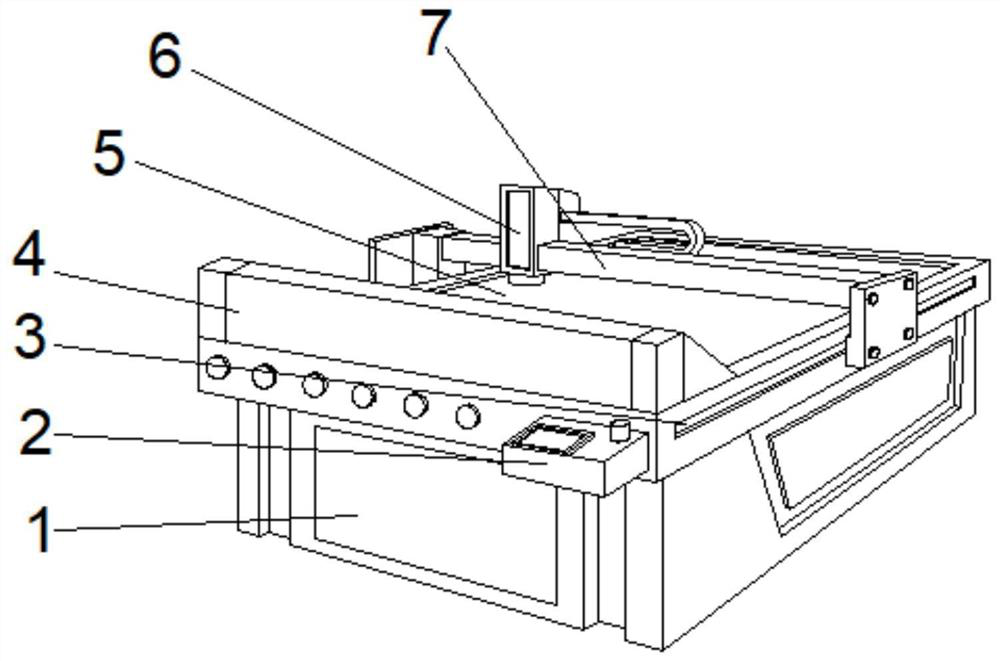

[0035] like Figure 1-2, a technical solution proposed by the present invention: a cutting device for rubber and plastic products, including a base 1, an operating table 5 is fixedly connected to the top of the base 1, a console 2 is fixedly connected to the right side of the front of the operating table 5, and the operating table 5 There is a chute 3 in the middle of the outer walls on both sides of the chute 3, and a moving frame 7 is arranged on the inner walls of both sides of the chute 3. The top of the moving frame 7 is located above the operating table 5 and the left side is provided with a cutting device 6. The front top of the operating table 5 The guard 4 is fixedly connected.

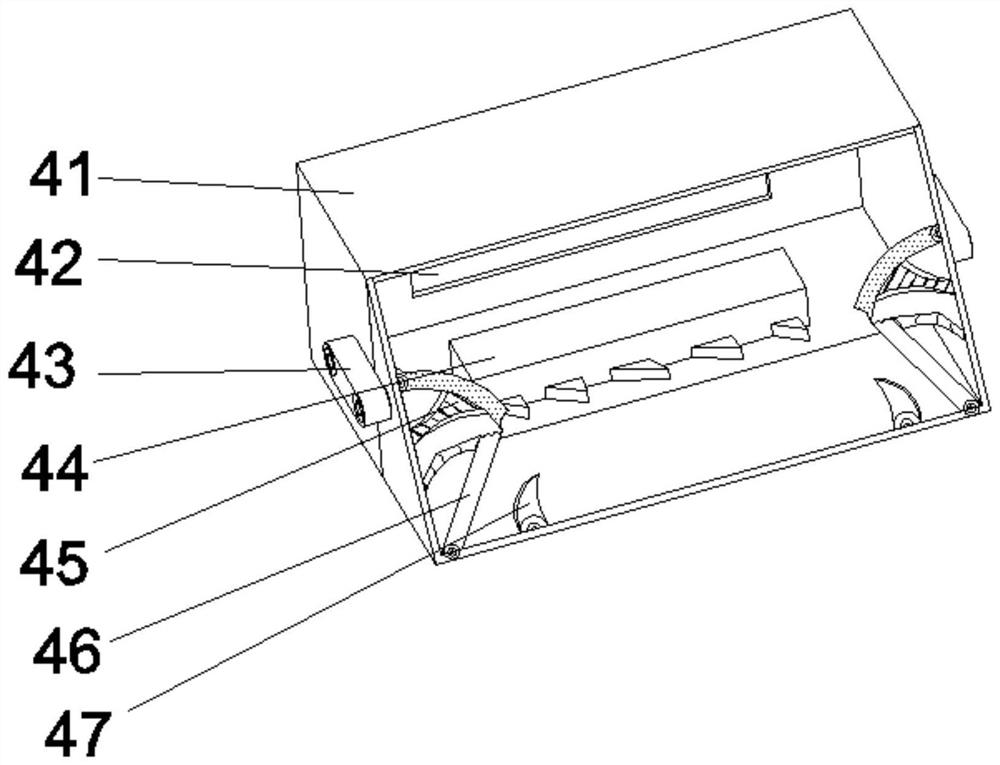

[0036] Wherein, the protection device 4 includes an outer frame 41, the middle part of the outer wall on both sides of the outer frame 41 is fixedly connected with a fixing member 43, the middle part of the back of the outer frame 41 is provided with an outlet 42, and the bottom of the inner ...

Embodiment 2

[0040] like Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the protective mechanism 44 includes a housing 441, the front bottom of the housing 441 is fixedly connected with a contact block 445, and the middle part of the inner wall on both sides of the housing 441 is provided with Outward expansion board 442, the front of outward expansion board 442 is fixedly connected with push rod 444, and the front of outward expansion board 441 is positioned at the both sides of push rod 444 and is provided with booster frame 443.

[0041] During use, place material on the console 5, press the start key on the console 2, the drive frame 7 drives the cutting device 6 to cut on the console 3 through the buffer 3, and pushes the pressing plate 46 by the push block 45 to make it The scraps after cutting are compacted, which is convenient for recycling and cleaning. The protective mechanism 44 further improves the efficiency of cleaning...

Embodiment 3

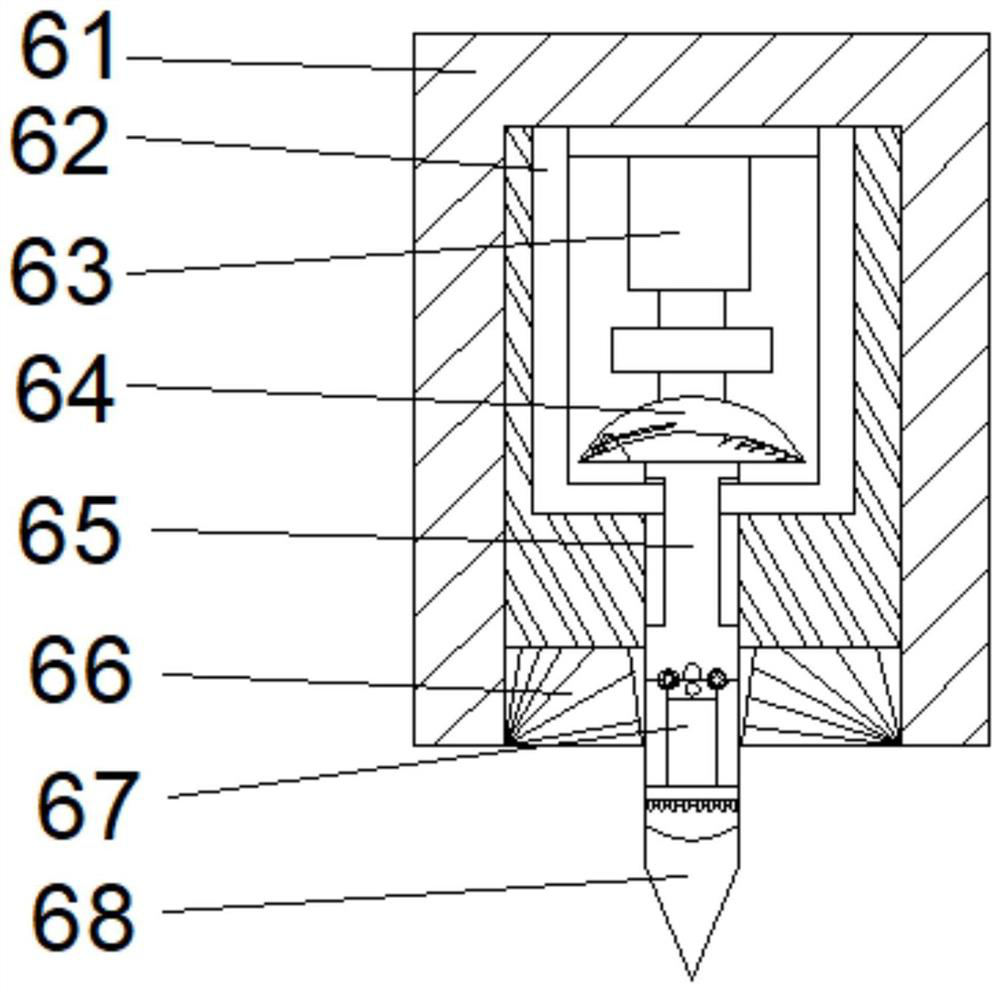

[0043] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the fixing mechanism 67 includes a force receiving block 671, and the tops of both sides of the force receiving block 671 are provided with outward swing blocks 672, and the outward swing blocks The front middle part of 672 is fixedly connected with connecting frame 673, and the middle part of connecting frame 673 is fixedly connected with elastic frame 674, and the left side of elastic frame 674 is provided with receiving plate 675, and the bottom of elastic frame 675 is fixedly connected with bottom plate 677, and the bottom The bottom of the set plate 677 is fixedly connected with an outer swing rod 678 , and the bottom of the outer swing rod 678 is fixedly connected with a linkage mechanism 676 .

[0044] Wherein, the linkage mechanism 676 includes a linkage frame 6761, the bottom of the linkage frame 6761 is fixedly connected with an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com