Intelligent multi-specification building board machining equipment

A technology for building boards and processing equipment, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of large foam bricks, waste of resources, and reduced efficiency, so as to speed up efficiency, reduce leftover materials, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

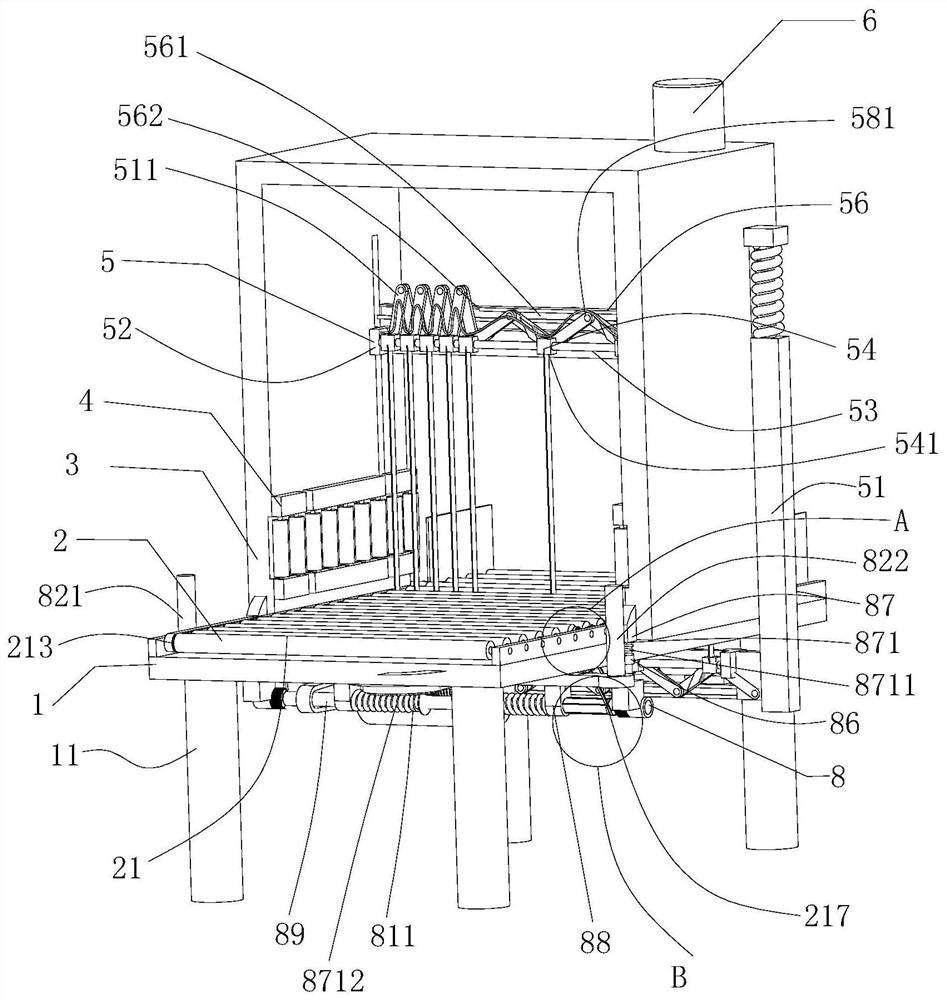

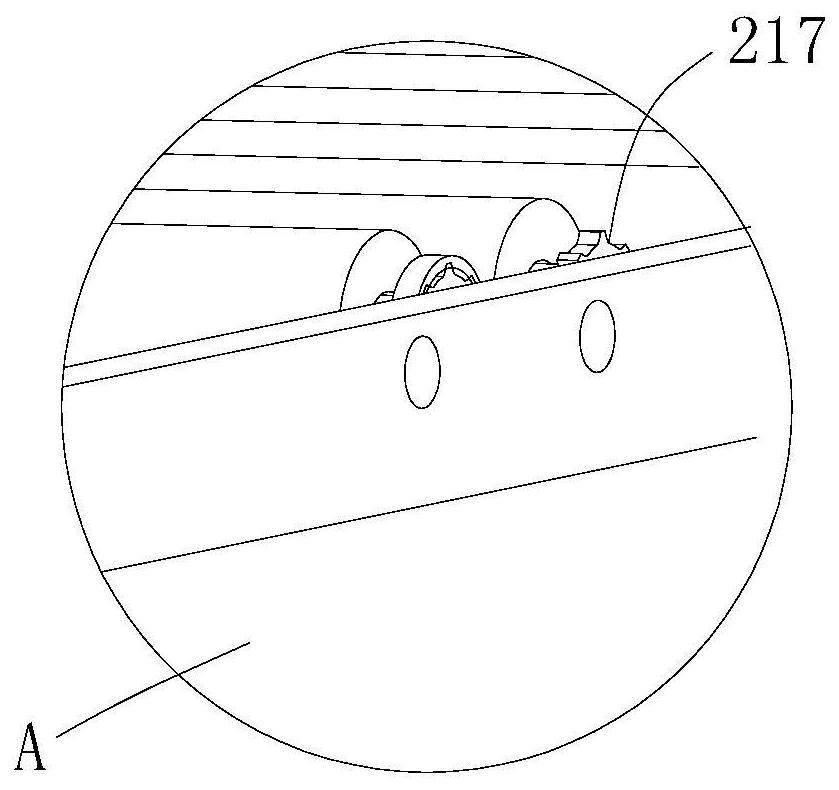

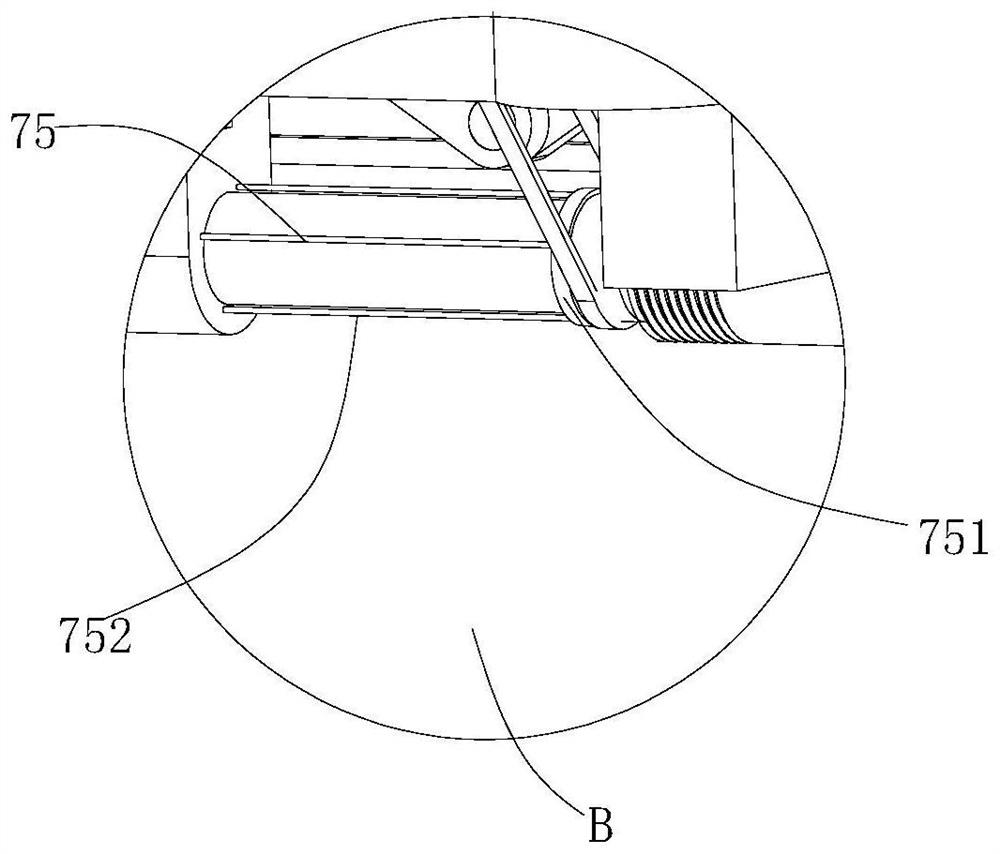

[0024] Such as Figure 1-9As shown, an intelligent multi-standard building board processing equipment, base 1, support feet 11, conveying structure 2, protection box 3, guide plate 4, knife holder 5, cooling device 6, driving device 7 and auxiliary guiding mechanism 8 The supporting feet 11 are located on the lower surface of the base; the conveying structure 2 is installed on the base 1; the protection box 3 is fixedly installed on the base 1; the guide plate 4 is fixedly installed on the protection The inner wall of the box 3; the tool holder 5 is slidably connected to the protective box 3; the cooling device 6 is arranged above the protective box 3; the driving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com