Nickel-titanium alloy wire rope and production process thereof

A nickel-titanium alloy and production process technology, which is applied in the direction of textiles, papermaking, textile cables, etc., can solve the problems of difficult anchorage at the end, brittle failure of SMA rods, self-resetting characteristics, hysteresis performance, and reduced energy consumption. Achieve superior mechanical and fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

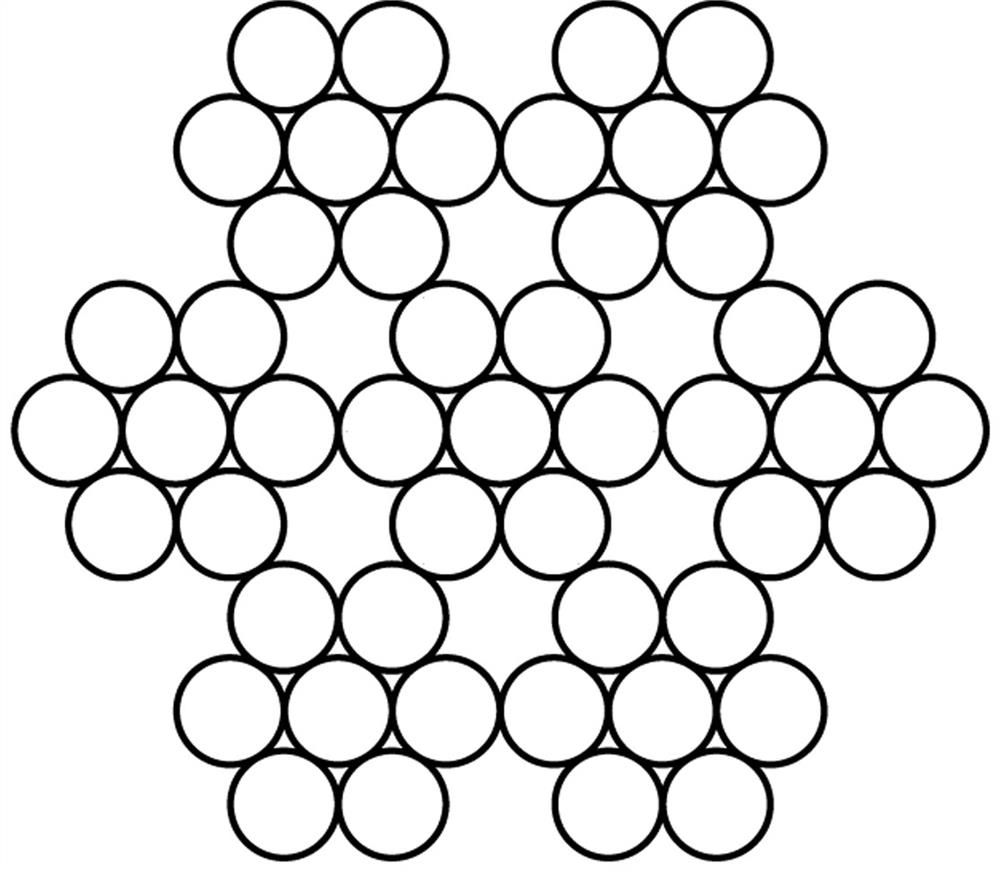

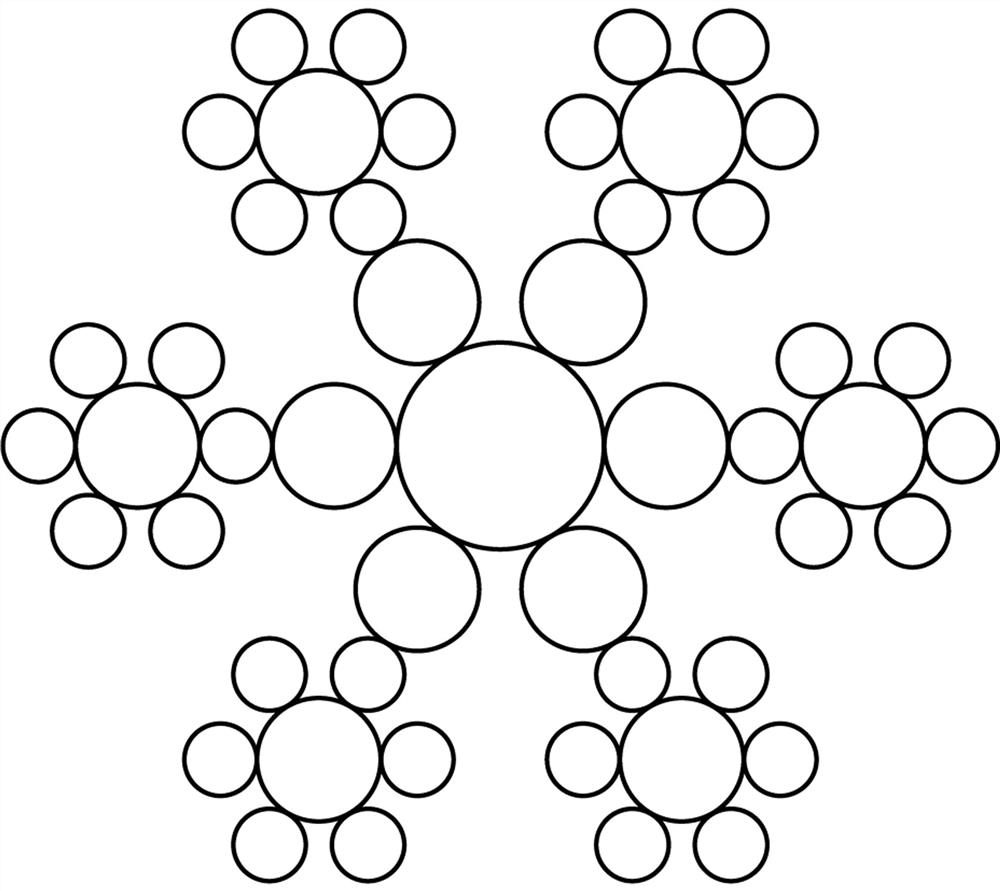

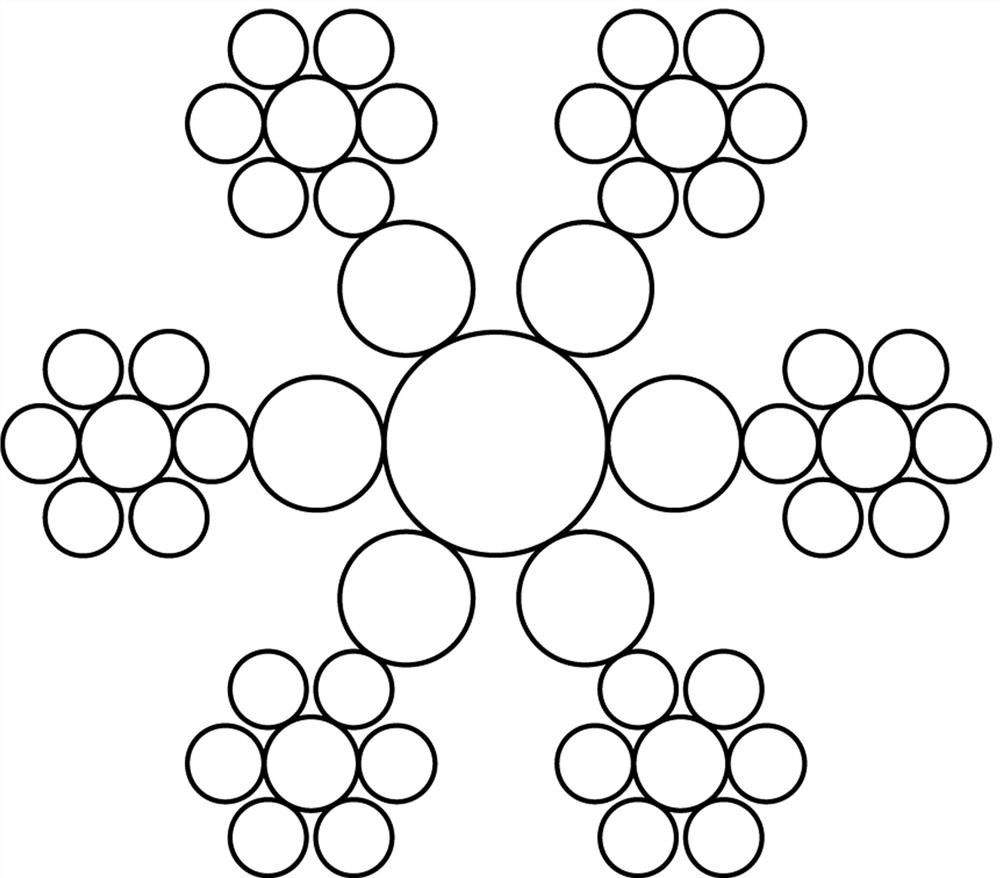

[0031] Such as figure 2 and image 3 As shown, a nickel-titanium alloy wire rope includes strands that are twisted together with the twist direction of the wire rope and the lay length of the wire rope, the strands include SMA strands that are twisted together, and the strands include 1 strand Core strands and 6 peripheral strands, the diameter of the core strands is greater than the diameter of the peripheral strands; the peripheral strands are wound around the core strands and twisted to form a bunch of SMA silk ropes;

[0032] The SMA wire strands include 1 core SMA wire and 6 peripheral SMA wires, the diameter of the core SMA wire is greater than the diameter of the peripheral SMA wire, and the peripheral SMA wire is twisted around the core SMA wire. share.

[0033] Such as Figure 4 As shown, due to the torsion structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com