Connection of prefabricated concrete-filled steel tubular column and sandwich concrete composition board and construction process

A technology of steel tube concrete columns and composite slabs, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low lateral stiffness, poor shear resistance, unbalanced bending moment, etc., and achieve high lateral stiffness and high bearing capacity , Good effect of transmitting internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

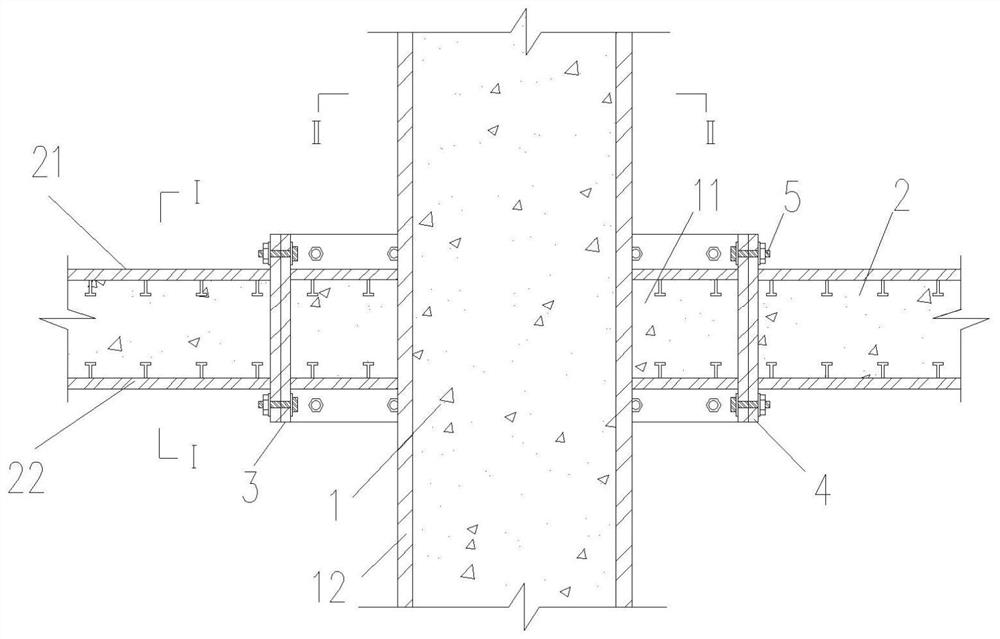

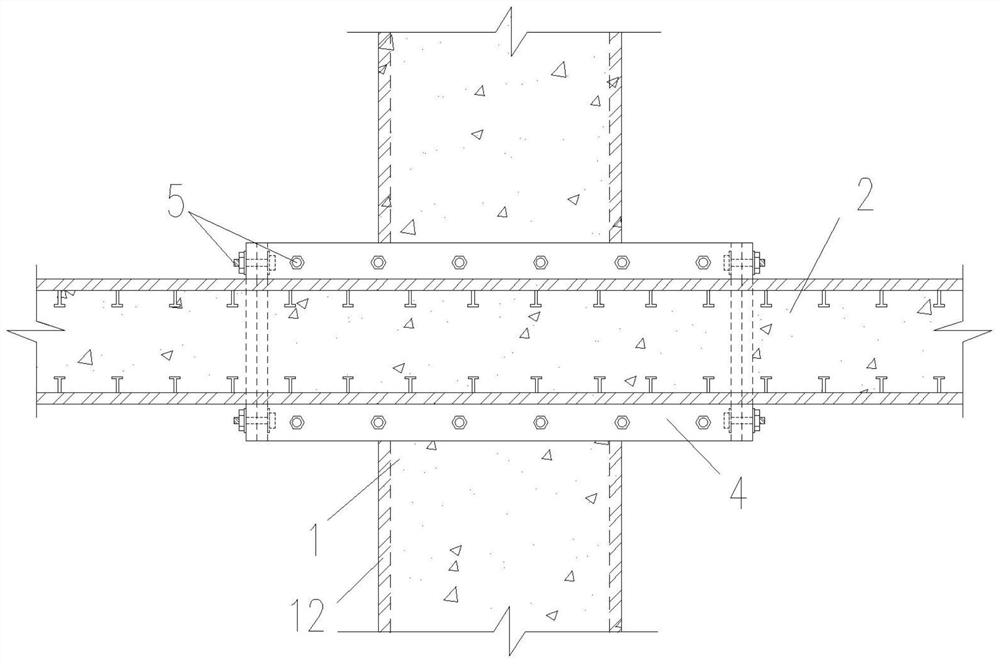

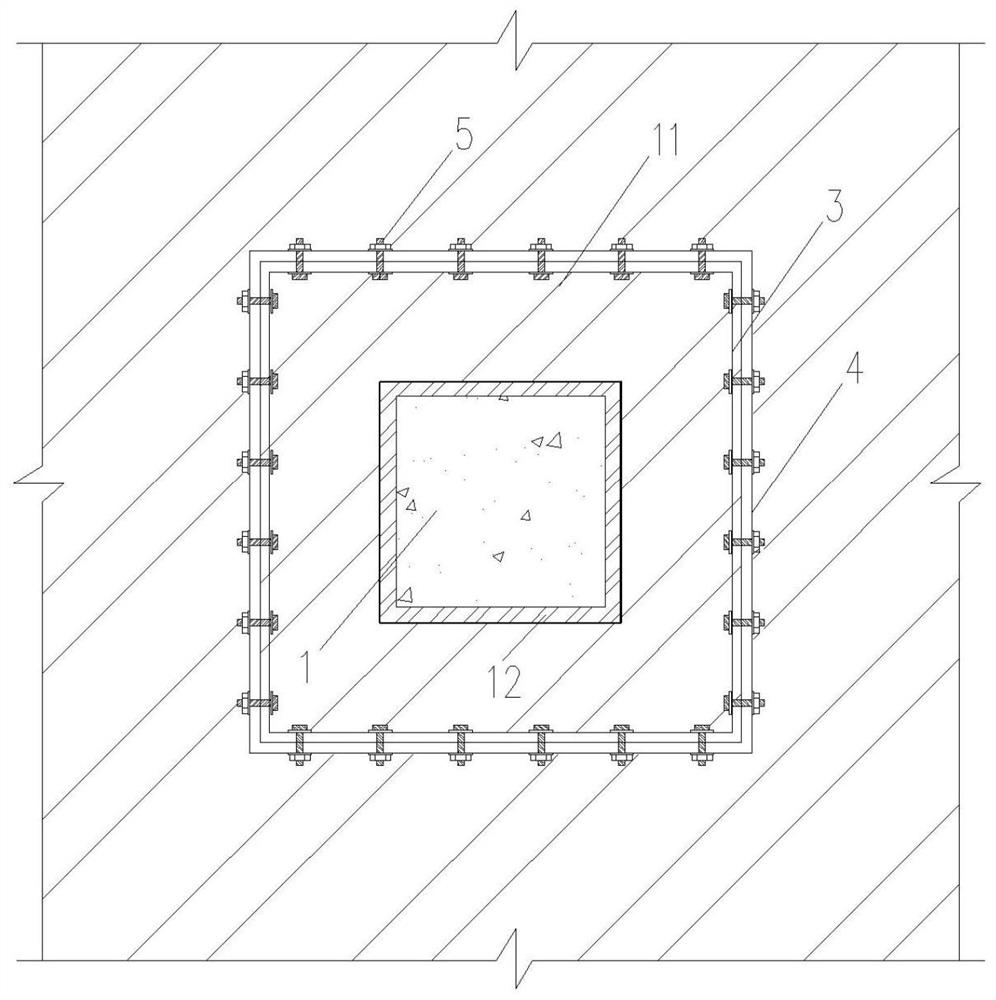

[0041] Embodiment 1: In the embodiment of the first aspect of the present invention, such as Figure 1 to Figure 8 As shown, the present invention provides a connection between a prefabricated steel tube concrete column 1 and a sandwich concrete composite panel, including a steel tube concrete column 1, a steel plate sandwich concrete composite panel 2 and a connecting assembly, and the steel tube concrete column 1 includes a steel tube 12 and an overhang The composite plate 11 has pouring concrete inside the steel pipe 12, and the overhanging composite plate 11 includes the steel plate of the outreaching composite plate 11, and a first connecting hole is arranged in the middle of the steel plate of the outreaching composite plate 11, and the steel pipe 12 passes through the first connecting hole, and is connected with the outer Stretched combined plate steel plate 111 is welded, and concrete is poured on the inside of the steel pipe 12 and the outer stretched plate combined st...

Embodiment 2

[0043] Embodiment 2: as Figure 1 to Figure 8 As shown, the connection assembly includes a first flange 3, a second flange 4 and a plurality of first bolts 5, the first flange 3 is annular, and the first flange 3 extends around The edge of the combined plate 11 is arranged and welded with the outer edge of the overhanging combined plate 11. The first flange 3 is provided with a plurality of third connection holes 31 in the upper direction, the second flange 4 is annular, and the second flange The disk 4 is arranged around the edge of the second connection hole of the steel plate sandwich concrete composite panel 2, and is welded to the edge of the second connection hole. The second flange 4 is provided with a plurality of fourth connection holes 41 in the upper direction, and the third connection hole 31 The position matches the position of the fourth connecting hole 41, and a plurality of first bolts 5 pass through the fourth connecting hole 41 and the third connecting hole 3...

Embodiment 3

[0045] Embodiment 3: as Figure 1 to Figure 4 As shown, the first flange 3 and the second flange 4 have the same shape.

[0046] In this embodiment, the first flange 3 and the second flange 4 have the same shape, so that the first flange 3 and the second flange 4 are more compatible, and then the steel pipe concrete column 1 and the steel plate sandwich concrete The combination board 2 is closely connected.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap