Tunnel connection channel rapid construction method based on telescopic steel pipe piece

A communication channel and construction method technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of high cost of steel pipe sheets, waste of materials, and inability to reuse steel pipe sheets, so as to reduce project cost, reduce disturbance, avoid The effect of surrounding rock instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present disclosure. Unless defined otherwise, all technical and scientific terms used in this disclosure have the same meaning as commonly understood by one of ordinary skill in the art to which this disclosure belongs.

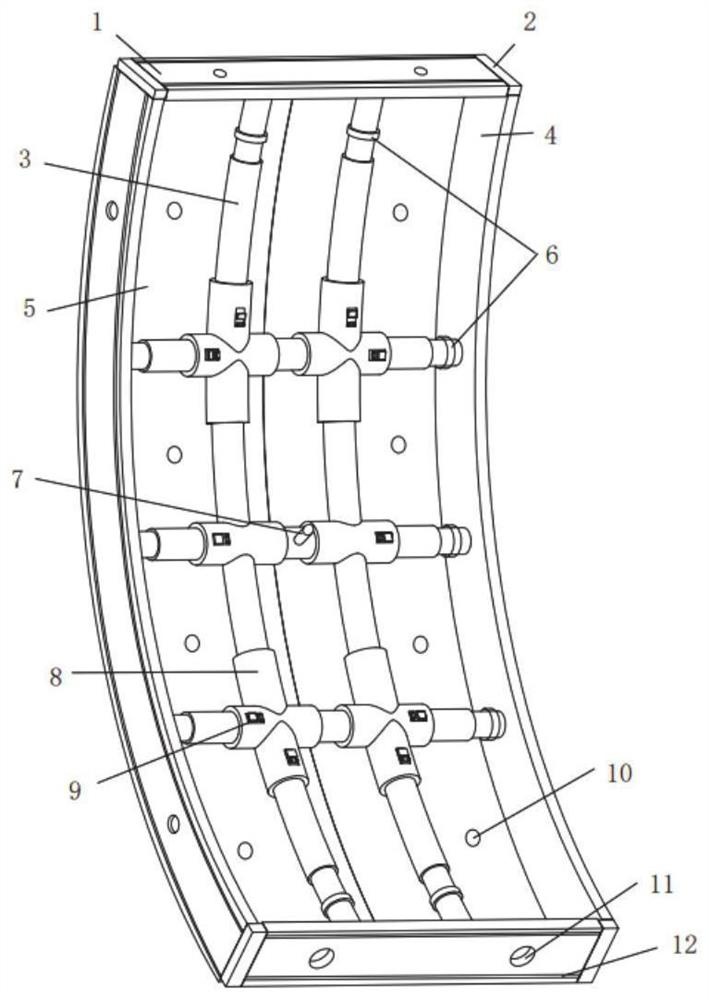

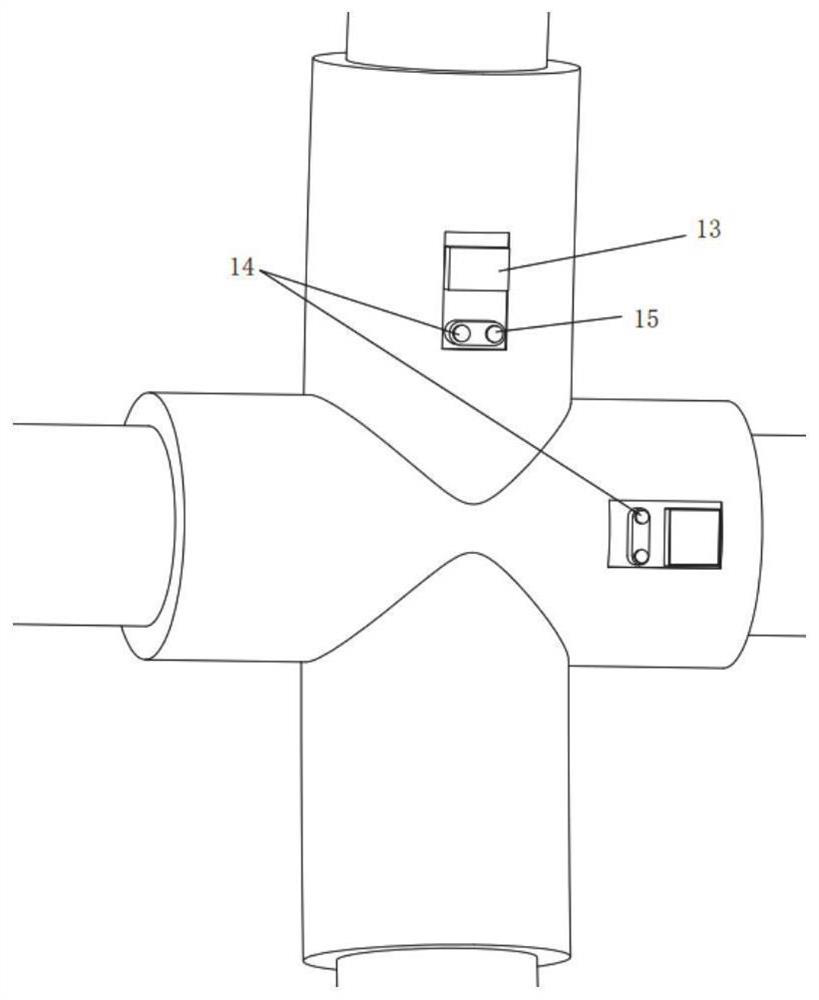

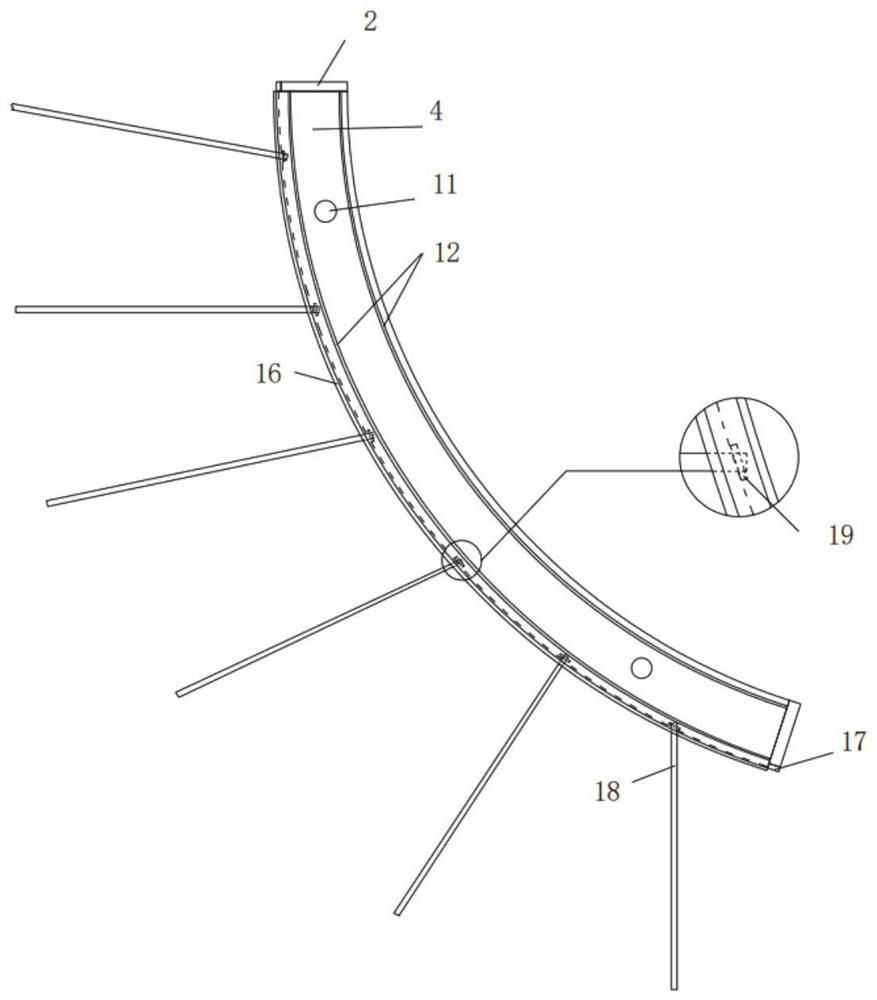

[0036] Such as figure 1 As shown, the implementation of the present disclosure provides a telescopic steel pipe sheet, which is mainly composed of a bearing plate, a hydraulic system 8 , a jack 3 , a hydraulic system 8 , and a lifting rod 7 .

[0037] The carrying plate includes a bottom carrying plate 5 with an arc-shaped surface, the bottom carrying plate is in the shape of a strip, the bottom carrying plate can be stretched in the width direction, and the arc is fixed in the width direction of the bottom carrying plate shaped bearing plate 4, the arc-shaped bearing plate 4 is perpendicular to the bottom bearing plate 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com