Combustion bed of Rijke pulse combustion device for gas fuel

A technology of pulsating combustion and gas fuel, which is applied in the direction of pulsating combustion, combustion chamber, combustion method, etc., can solve the problems of uneven distribution of gas fuel, inability to stimulate pulsating combustion, and unstable pulsating combustion, so as to improve the uniformity of gas distribution, Guaranteed service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

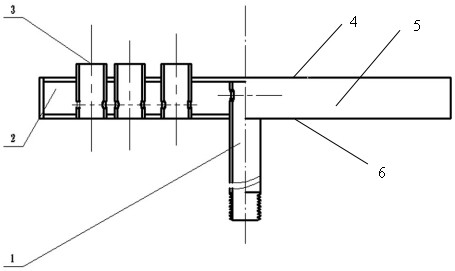

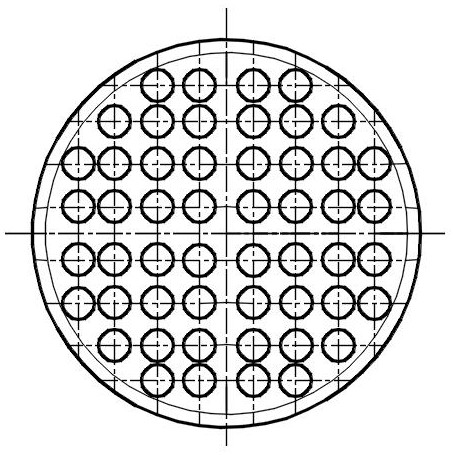

[0029] Such as figure 1 As shown, the combustion bed of the Rick-type pulsation combustion device used for gas fuel in the present invention mainly includes an intake pipe 1, a distribution chamber 2 and a combustion thin tube 3, and the combustion bed is placed at 1 / 4~1 of the bottom of the pulsation burner. / 3L.

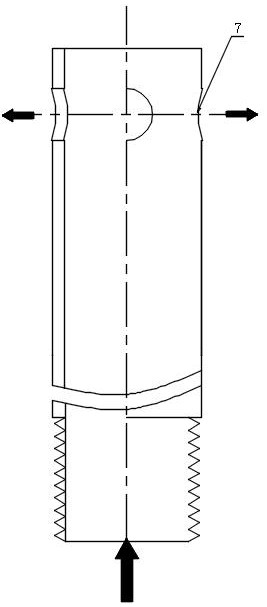

[0030] Such as image 3 As shown, the intake pipe is a straight pipe structure, the length is determined by the structure of the burner, the bottom end is a G3 / 4' pipe threaded port, which is used to fix the gas intake, and the top end is the gas outlet distribution port, which withstands the upper distribution plate; on the side of the gas distribution port The wall is uniformly provided with 4 gas outlet holes 7 with equal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com