Hardness detection device for all-glass vacuum blank tube

A detection device and an all-glass technology are applied in the direction of measuring devices, testing material hardness, strength characteristics, etc., and can solve problems such as waste disposal of unsuitable pipe materials and hazards to the safety of testing personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

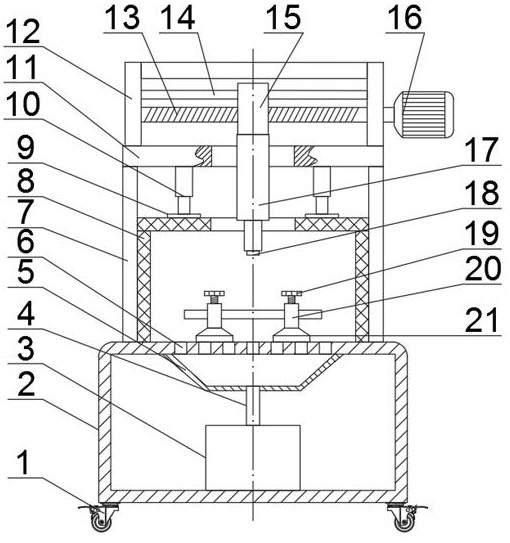

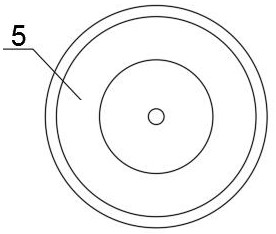

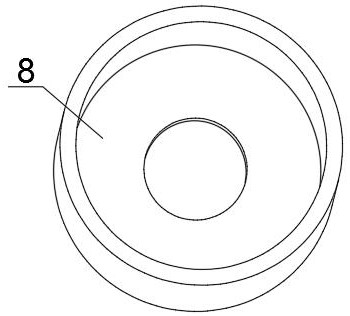

[0025] see Figure 1-3 , an all-glass vacuum blank tube hardness testing device, comprising a box body 2, a support plate 7 is fixedly connected to both sides of the upper part of the box body 2, a top plate 11 is fixedly connected to the top of the support plate 7, and a mounting frame 12 is installed on the top of the top plate 11 , the right side of the mounting frame 12 is fixedly connected with a driving motor 16, the driving motor 16 is a servo motor, and the left side of the driving motor 16 is fixedly connected with a screw mandrel 13, the screw mandrel 13 is rotationally connected with the mounting frame 12, and the screw mandrel 13 is threaded in the middle There is a moving block 15, the upper part of the moving block 15 is slidably connected with a guide shaft 14, the lower part of the moving block 15 is fixedly connected with an electric telescopic rod 17, the lower part of the electric telescopic rod 17 is equipped with a pressure sensor 18, and the lower part of ...

Embodiment 2

[0027] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the lower part of the box body 2 is fixedly connected with a traveling wheel 1, and the traveling wheel 1 is a universal wheel with a brake. The wheels are convenient for moving and carrying the device, saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com