A test device and test method

A test device and socket technology, which is applied in the direction of measuring device, measuring device casing, single semiconductor device testing, etc., can solve problems such as unstable contact between the object to be measured and the probe, damage to the object to be measured and the probe, and achieve sensitivity Guaranteed, wear-resistant, spill-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

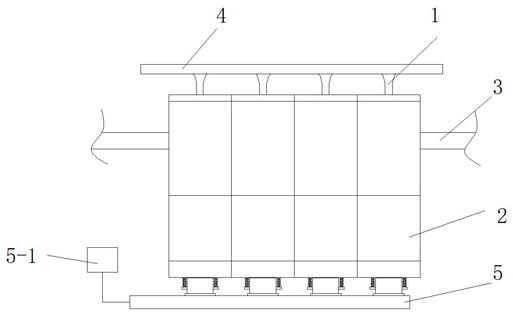

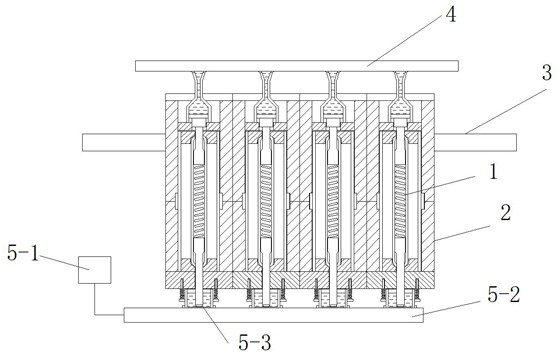

[0045] Such as Figure 1-8 As shown, a probe testing device in this embodiment includes a probe 1 , a socket 2 , a support frame 3 , and a test member 5 .

[0046] The probe 1 is arranged in the socket 2, the socket 2 is fixed between the object 4 to be measured and the test member 5 through the support frame 3, the lower end surface of the object 4 to be measured is electrically connected to the upper end of the probe 1 installed in the socket 2, The lower end of the probe 1 is electrically connected with the test member 5 through the socket 2 .

[0047] The socket 2 can be detachably installed on the support frame 3, and the position of the socket 2 can be adjusted by controlling the support frame 3 through the driver. At the same time, the socket can be fixed, and the object 4 to be measured is set on a device that can be adjusted and fixed. To satisfy the fixing and moving of the object 4 to be measured.

[0048] When the object to be measured is moved by the instrument,...

Embodiment 2

[0063] A socket disclosed in this embodiment includes: an upper unit 2-1, a spacer 2-2, a first cover 2-3, a lower unit 2-4, a second cover 2-5, and a connector 2- 6.

[0064] Both the upper unit 2-1 and the lower unit 2-4 are square tubes with cuboid cavities inside to fully adapt to the shape of the columnar tube 1-1. The columnar tube 1-1 is square.

[0065] The upper unit 2-1 is provided with a spacer 2-2 inside, and the top of the upper unit 2-1 is provided with a first cover plate 2-3, and the opening end of the upper unit 2-1 is correspondingly connected with one end of the lower unit 2-4 . The other end of the lower unit 2-4 is provided with a second cover plate 2-5, and the lower end of the second cover plate 2-5 is provided with a connecting piece 2-6.

[0066] The upper unit 2-1 and the lower unit 2-4 have corresponding grooves on the inner wall of the corresponding connection opening, and the cylindrical pipe 1-1 is arranged on the upper unit 2-1 and the lower un...

Embodiment 3

[0075] A test method, comprising the following steps;

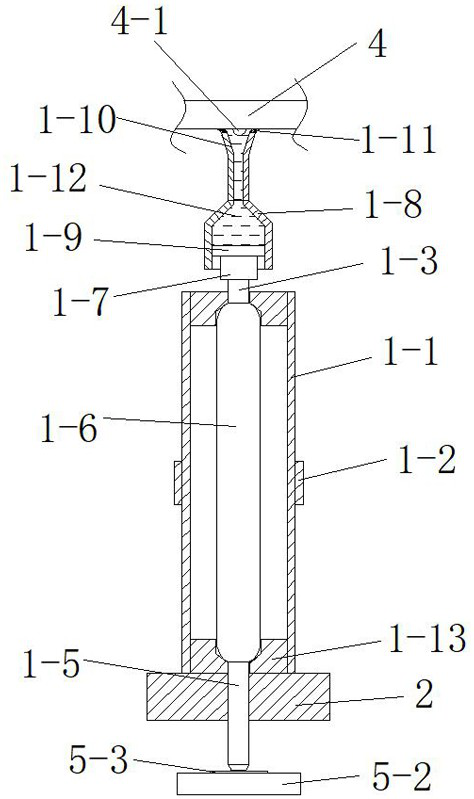

[0076] Step a, the point to be measured, selecting the electrical contact 4-1 to be measured on the object 4 to be measured for marking;

[0077] Step b, forming a closed circuit, the installed socket, by fine-tuning the support frame 3 so that the funnel-shaped tube 1-10 is aligned with the electrical contact 4-1 to be tested, and at the same time make the sealing ring 1-11 and the lower part of the object 4 to be tested The surface is fully attached, and the wiring board 5-2 is pushed upward by the driver, so that the lower end of the second column end 1-5 is completely against the welding pad 5-3, and reaches the upper end of the liquid holding tube 2-6-1 Abut against the lower end surface of the second cover plate 2-5, so that the lower end of the liquid holding pipe 2-6-1 and the upper end surface of the welding pad 5-3 form a closed space for liquid injection to form a preliminary closed circuit;

[0078] Step c, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com