Waveguide optical fiber alignment coupling transmission structure and production process

A technology for optical fiber alignment and transmission structure, which is applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of inability to carry out high-efficiency mass production, complicated process methods, and low production efficiency, so as to facilitate maintenance and repair , good connection reliability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

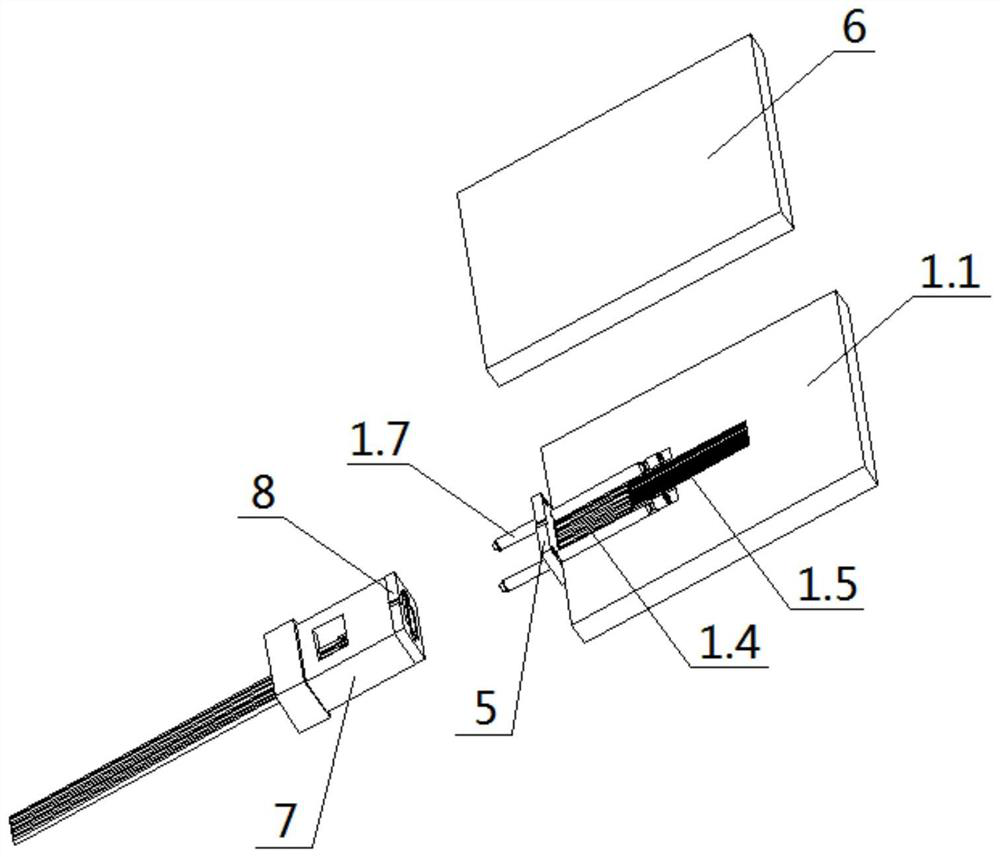

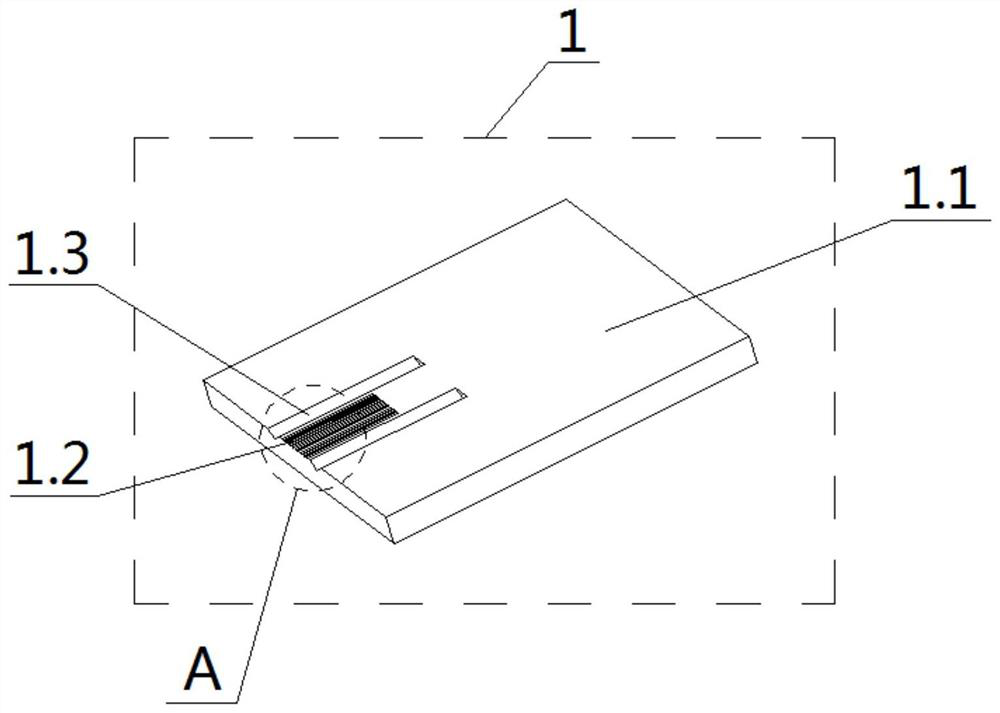

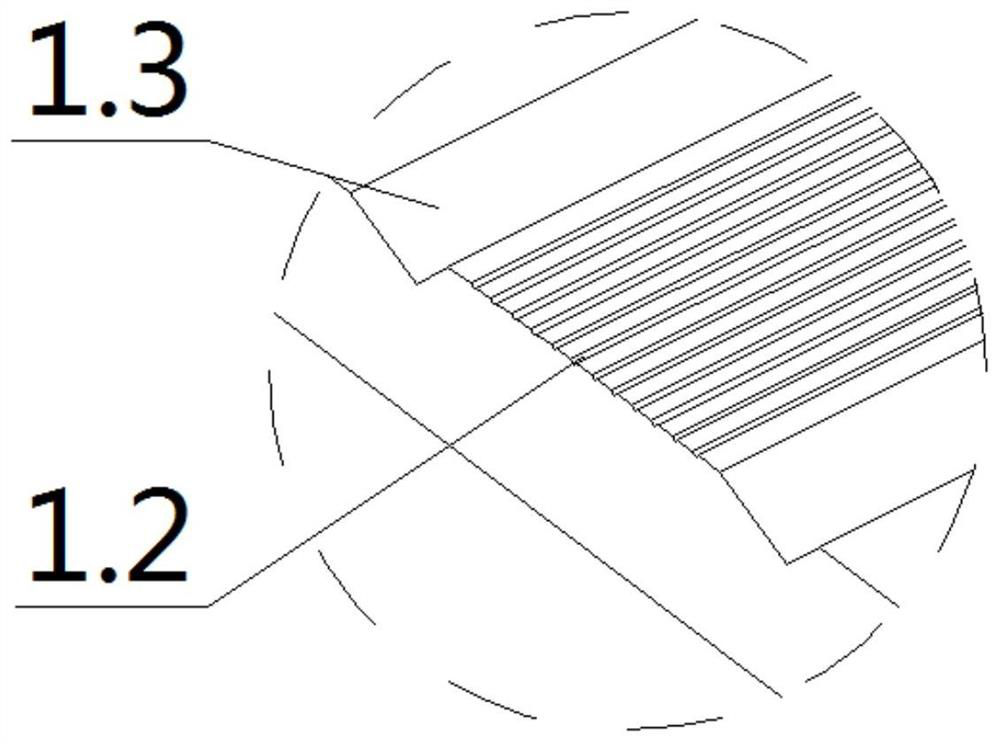

[0030] A waveguide alignment coupling transmission structure through an optical fiber, including an optical waveguide plate 1; the optical waveguide plate 1 includes an optical waveguide substrate 1.1, a hollow fiber 1.4, a waveguide 1.5, and a guide pin 1.7; the upper surface of the optical waveguide plate 1 is close to An array of pre-embedded optical fiber V-shaped grooves 1.2 is arranged on the edge of the board, and guide pin V-shaped grooves 1.3 are arranged on both sides of the embedded optical fiber V-shaped groove 1.2; one end of the hollow fiber 1.4 is a solid fiber segment 1.4.1, and the other end is a hollow The optical fiber section 1.4.2 has a circular cavity in the middle of the hollow optical fiber section 1.4.2; the hollow optical fiber 1.4 is fixed in the pre-embedded optical fiber V-shaped groove 1.2 with the solid optical fiber section 1.4.1 facing outward; the guide pin 1.7 Fixedly arranged in the guide pin V-shaped groove 1.3; the waveguide 1.5 is connecte...

Embodiment 2

[0032] A waveguide alignment coupling transmission structure through an optical fiber, including an optical waveguide plate 1; the optical waveguide plate 1 includes an optical waveguide substrate 1.1, a hollow fiber 1.4, a waveguide 1.5, and a guide pin 1.7; the upper surface of the optical waveguide plate 1 is close to An array of pre-embedded optical fiber V-shaped grooves 1.2 is arranged on the edge of the board, and guide pin V-shaped grooves 1.3 are arranged on both sides of the embedded optical fiber V-shaped groove 1.2; one end of the hollow fiber 1.4 is a solid fiber segment 1.4.1, and the other end is a hollow The optical fiber section 1.4.2 has a circular cavity in the middle of the hollow optical fiber section 1.4.2; the hollow optical fiber 1.4 is fixed in the pre-embedded optical fiber V-shaped groove 1.2 with the solid optical fiber section 1.4.1 facing outward; the guide pin 1.7 Fixedly arranged in the guide pin V-shaped groove 1.3; the waveguide 1.5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com