Method for monitoring maximum deformation in lifting process of large structure

A technology with maximum deformation and large structures, applied in structured data retrieval, special data processing applications, instruments, etc., can solve the problems of small allowable deformation, few application scenarios, large structure deformation, etc., to achieve simple operation, Wide adaptability and visible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

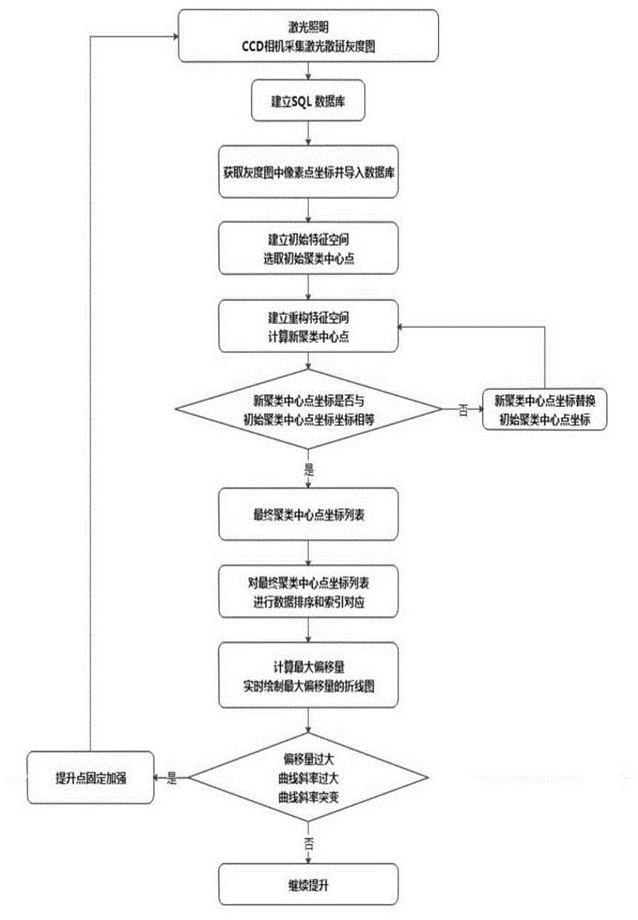

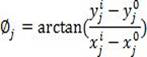

[0024] The working principle of the present invention is: 1. First irradiate the surface of the structure with laser light to form approximately circular speckles. At this time, the rows and columns of the speckles are parallel to each other, and the size of each speckle is similar and the distribution is uniform; 2. During the lifting process These speckles will change in position and shape, but since the deformation of large structures is a small deformation, the rows and columns of the speckle can still be regarded as approximately parallel during the lifting process; 3. In each speckle, select A small pixel is used as an approximate replacement of the speckle position; 4. Calculating the offset of these corresponding pixels can approximately replace the offset of these laser speckles, and monitor the deformation of the surface of the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com