A heat dissipation structure of a wireless charging coil and its manufacturing method

A technology of wireless charging and manufacturing methods, applied in coil manufacturing, inductance/transformer/magnet manufacturing, charging stations, etc., can solve the problems that the strength of silica gel cannot meet the requirements, etc., and achieve strong machinability, wide application range, and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be understood that these descriptions are exemplary only and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

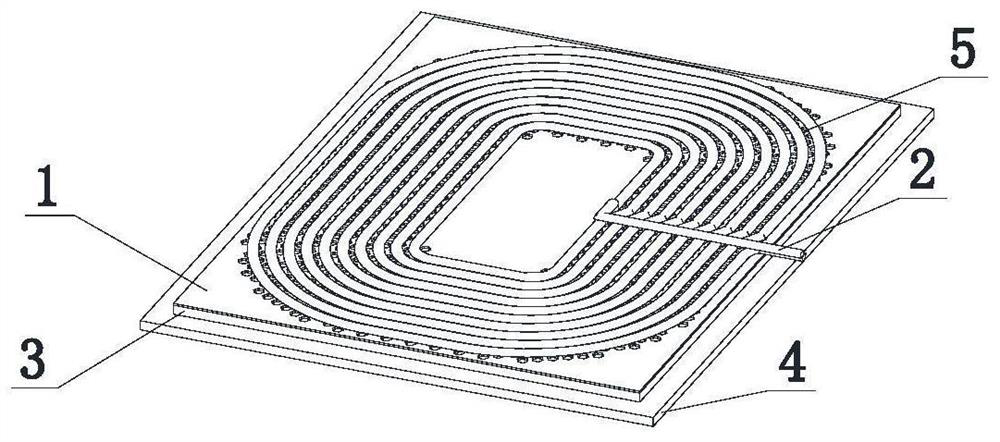

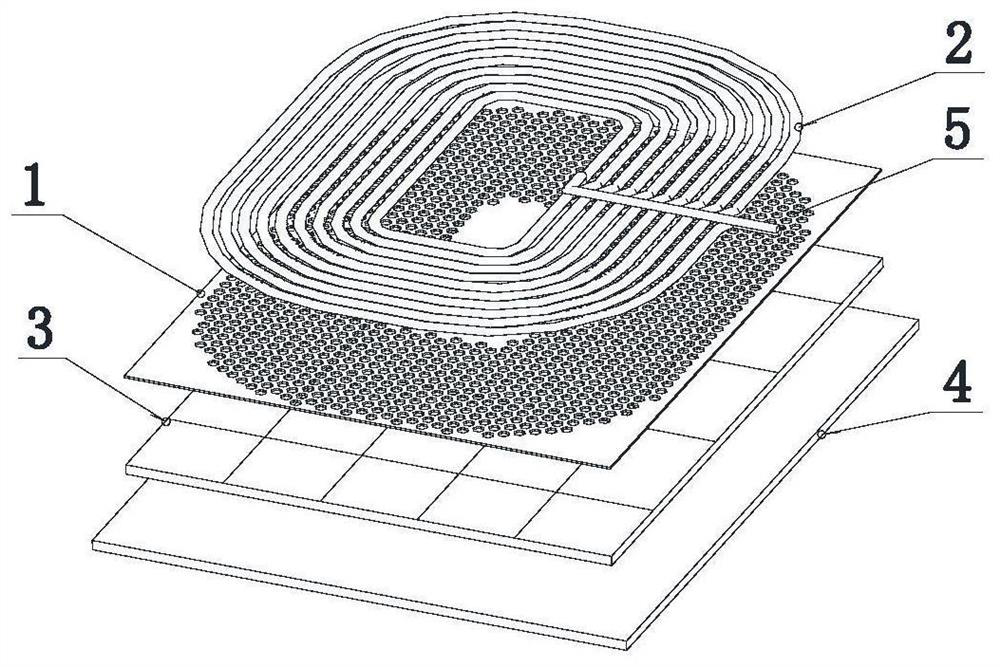

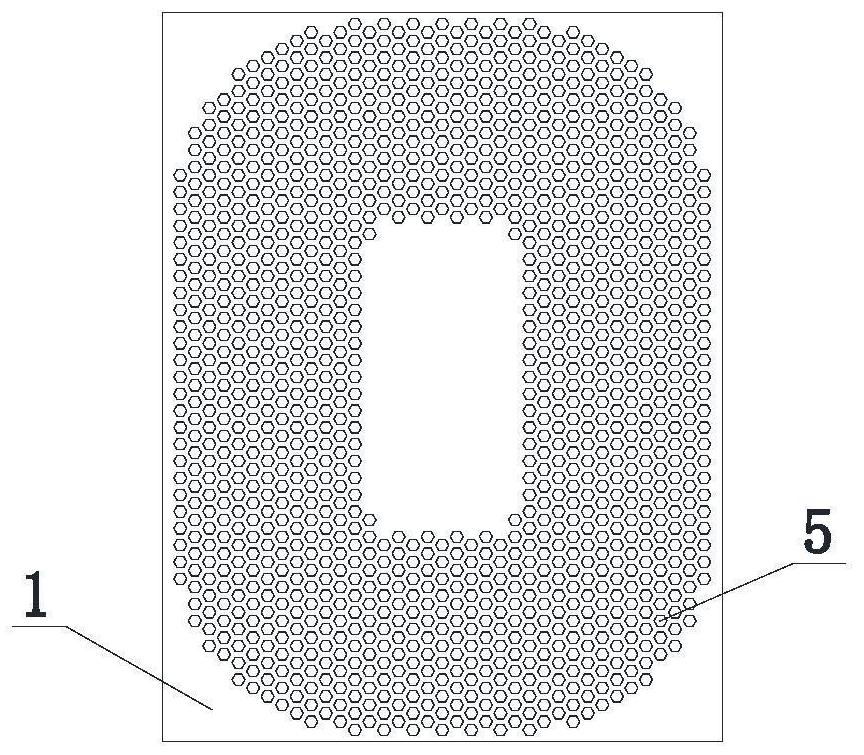

[0024] Provide a heat dissipation structure of a wireless charging coil, such as figure 1 , figure 2 As shown, it includes an insulating plate 1 and a filler 5 filled in the mesh of the insulating plate 1 .

[0025] An insulating plate is provided between the coil 2 that generates the magnetic field and the magnetic core 3 that enhances the magnetic field. The magnetic core 3 is fixed to the core-fixed aluminum plate case 4 . The heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com