Rolling brush with shearing function, dust collector floor brush head comprising rolling brush and dust collector

A vacuum cleaner and functional technology, applied in the direction of vacuum cleaners, brushes, suction nozzles, etc., can solve the problem that hair cannot be rotated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

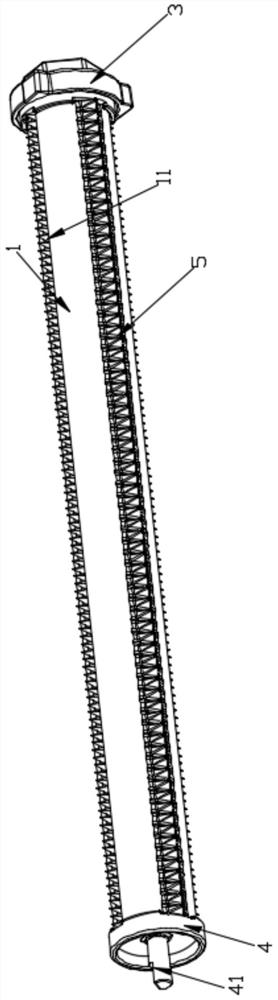

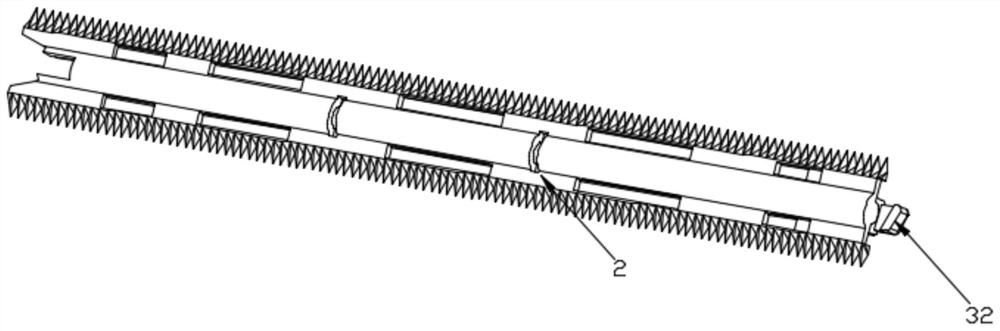

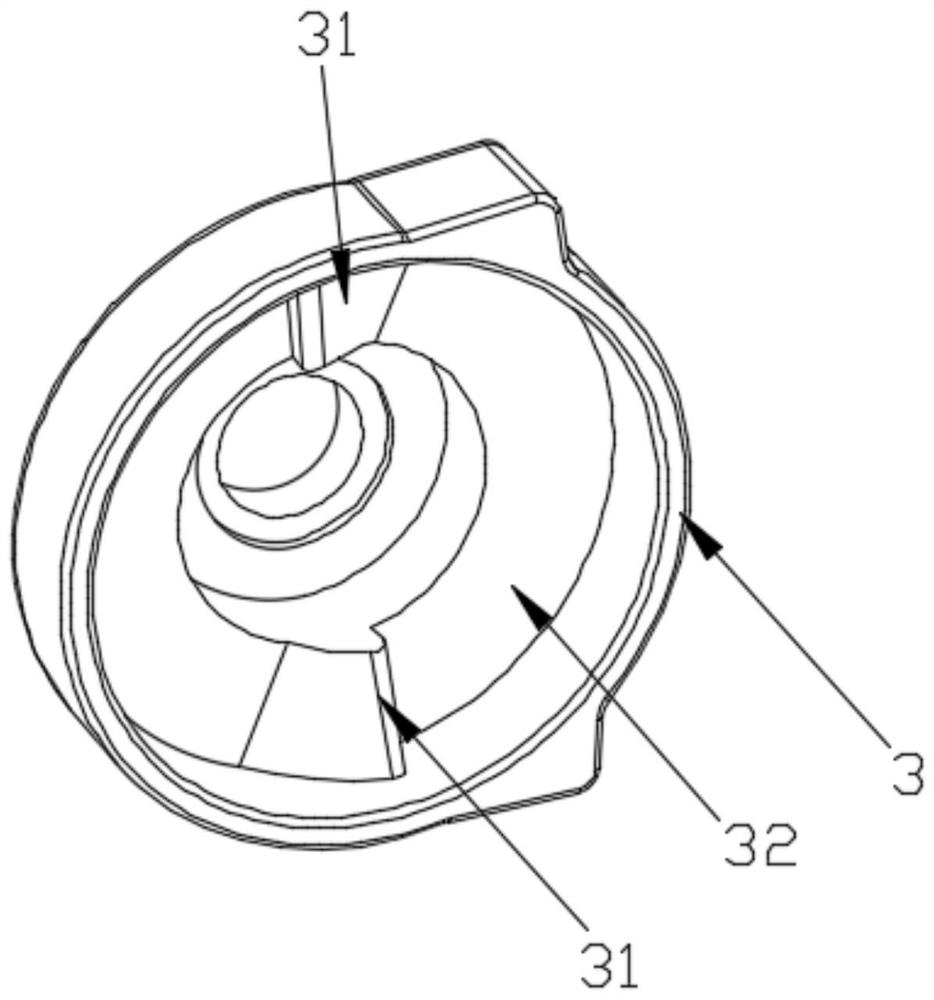

[0027]See attachedfigure 1 with2As shown, this embodiment provides a rolling brush with a shearing function, which includes an outer brush barrel 1 and a blade 2. The blade 2 has a saw-toothed blade. The blade extends from the blade adjusting groove 11, and the blade 2 can move along Move along the blade adjusting slot 11. Two blade adjusting grooves 11 are provided on the outer brush barrel 1 of this embodiment, and the phase difference between the two blade adjusting grooves 11 is 180 degrees. The main body of the blade 2 is located inside the outer brush barrel 1. The cross section of the blade 2 in this embodiment is semicircular, and the cutting edges are arranged on two opposite outer edges of each blade 2. There are two blades 2 in this embodiment, and they are arranged oppositely, and the cutting edges of the two blades 2 They are attached to each other and respectively extend from the blade adjusting groove 11.

[0028]The rolling brush of this embodiment also includes a pushi...

Embodiment 2

[0033]The difference between this embodiment and the first embodiment is that the mobile base 33 is a ring-shaped slope (see attachedFigure 5 As shown), when the moving head rotates and moves along the moving base 33, under the guidance of the slope of the moving base 33, the moving head drives the blade 2 to move along the surface of the moving base 33 and synchronize Move along the axial direction of the roller brush. See attachedImage 6 As shown, the moving head of this embodiment further includes a rotating wheel 34 that can abut against the moving base 33, and the rotating wheel 34 can ensure that the moving head moves smoothly along the surface of the moving base 33.

Embodiment 3

[0035]See attachedFigure 7As shown, this embodiment is a brush head of a vacuum cleaner, which includes the rolling brush with shearing function of Embodiment 1 or Embodiment 2, and also includes a second rolling brush 6 arranged in parallel with the rolling brush of Embodiment 1. And the floor brush housing 7, and the second rolling brush 6 is arranged close to the rolling brush of the first embodiment. A dust outlet 71 is provided in the middle of the rear end of the floor brush housing 7. The rolling brush with shearing function and the second rolling brush 6 are aligned with the dust outlet 71, and the rolling brush with shearing function is located near the dust outlet. The position of 71 and the height of its lower surface is higher than the height of the lower edge of the floor brush housing 7, therefore, the blade 2 will not damage the ground etc. during use. When in use, the second roller brush 6 is located near the front of the brush head of the vacuum cleaner, and the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com