Preparation method and application of functionalized graphene capable of improving performance of lubricating oil

A technology of lubricating oil and graphene, applied in the polymer and its application field, can solve the problems of precipitation, easy agglomeration of graphene, inability to stably disperse for a long time, etc., to reduce friction coefficient, small sheet diameter, improve lubrication and mechanical The effect of repairing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

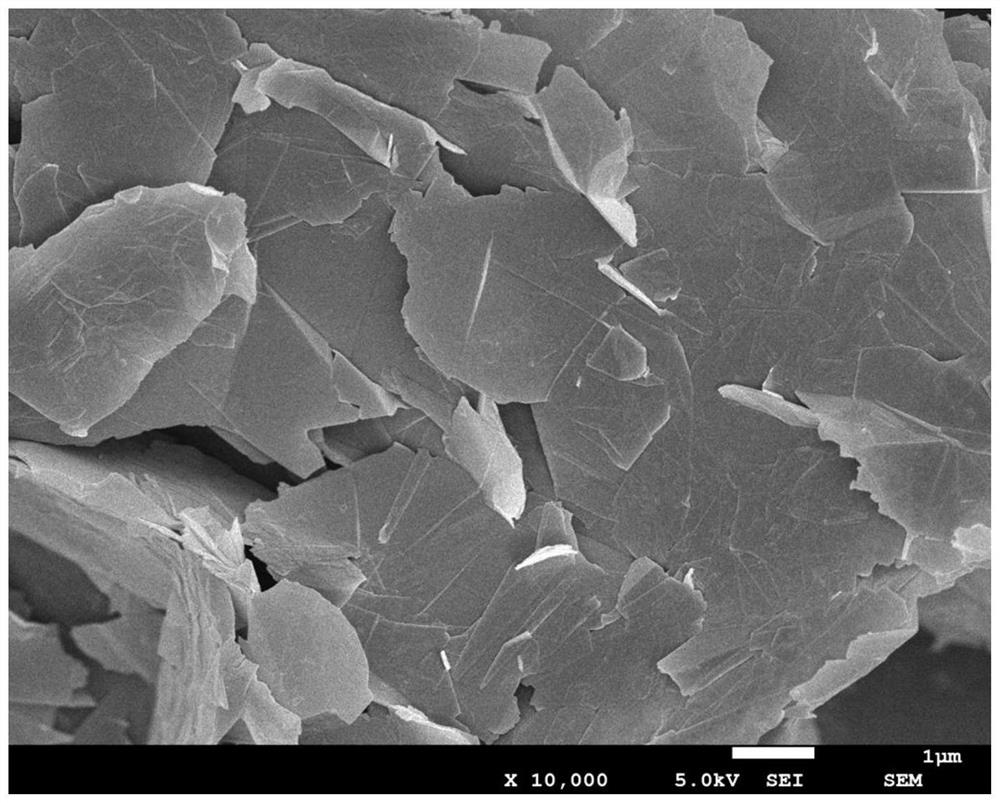

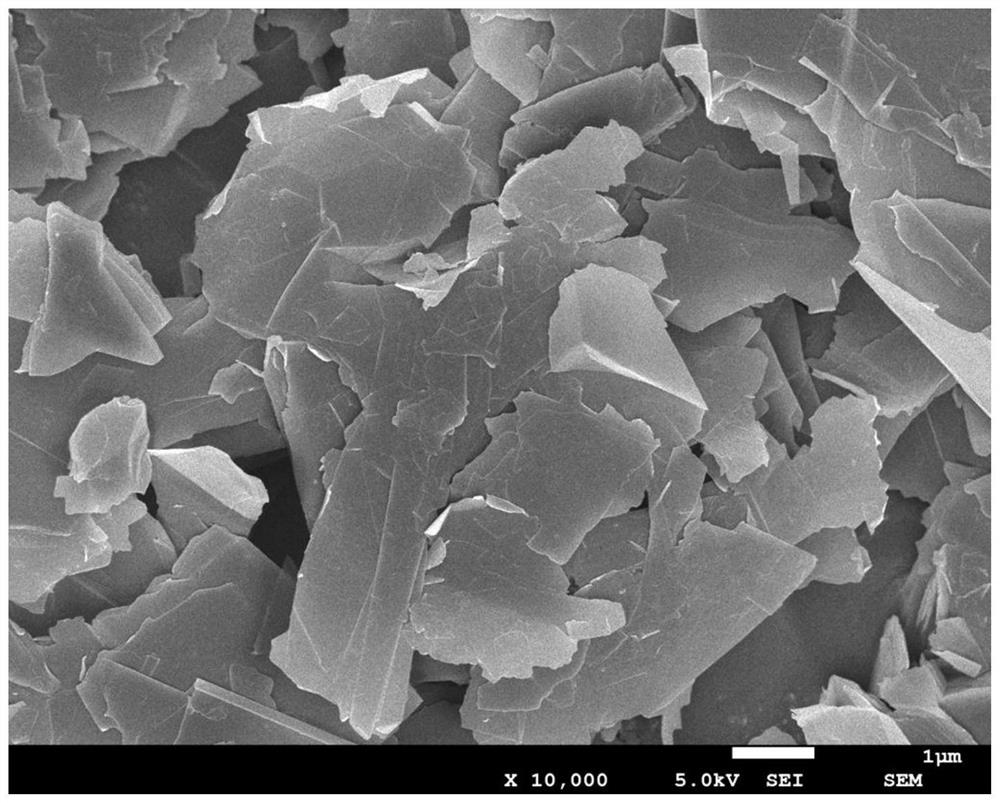

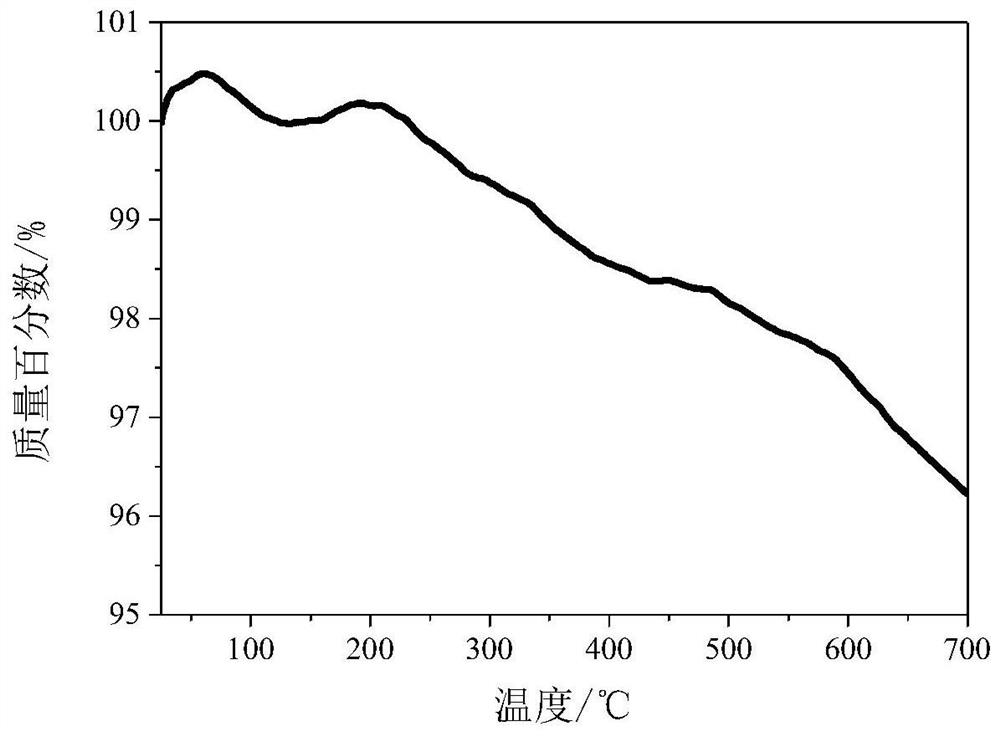

[0034] The preparation method of the functionalized graphene that can improve the performance of lubricating oil, the specific steps are as follows:

[0035] Step 1. Dissolution: Dissolve the modifier into the solvent and disperse it fully and evenly; among them, the modifier is silane coupling agent KH-550, silane coupling agent KH-560, silane coupling agent KH-570, silane coupling agent Coupling agent KH-580, silane coupling agent KH-590, silane coupling agent A-172, silane coupling agent Si-69, oleic acid, diphenyldimethoxysilane, dimethylmethoxysilane and Any one or a mixture of two or more of octyltrimethoxysilanes may be used. The solvent is any one or a mixture of two or more of acetone, ethanol, methanol, isopropanol, benzene, toluene, chloroform, ether, carbon tetrachloride and carbon disulfide, and the mass ratio of the modifier to the volume of the solvent is 1:20. According to the needs of the experiment, the ratio of modifier mass to solvent volume can be select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com