Automatic spraying dust removal device along with wind power in building foundation pit

A technology of dust removal device and foundation pit, which is applied in the direction of dust removal, combined device, and use of liquid separation agent, etc., which can solve the problems of high dust content, poor working environment, and inability to reduce dust, and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

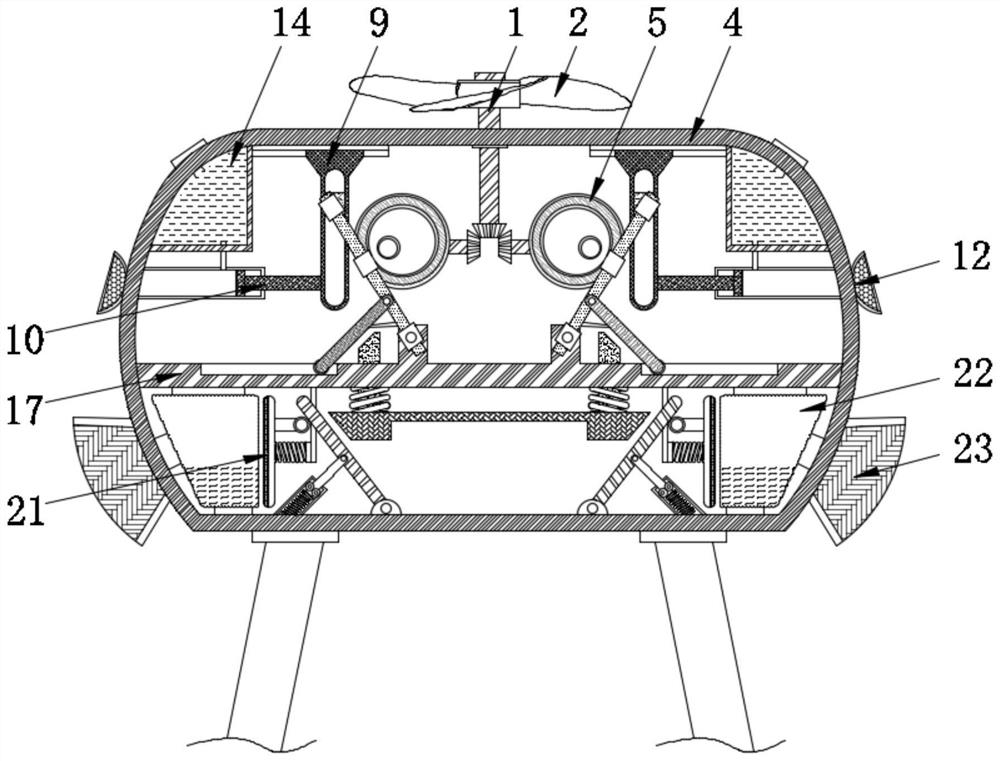

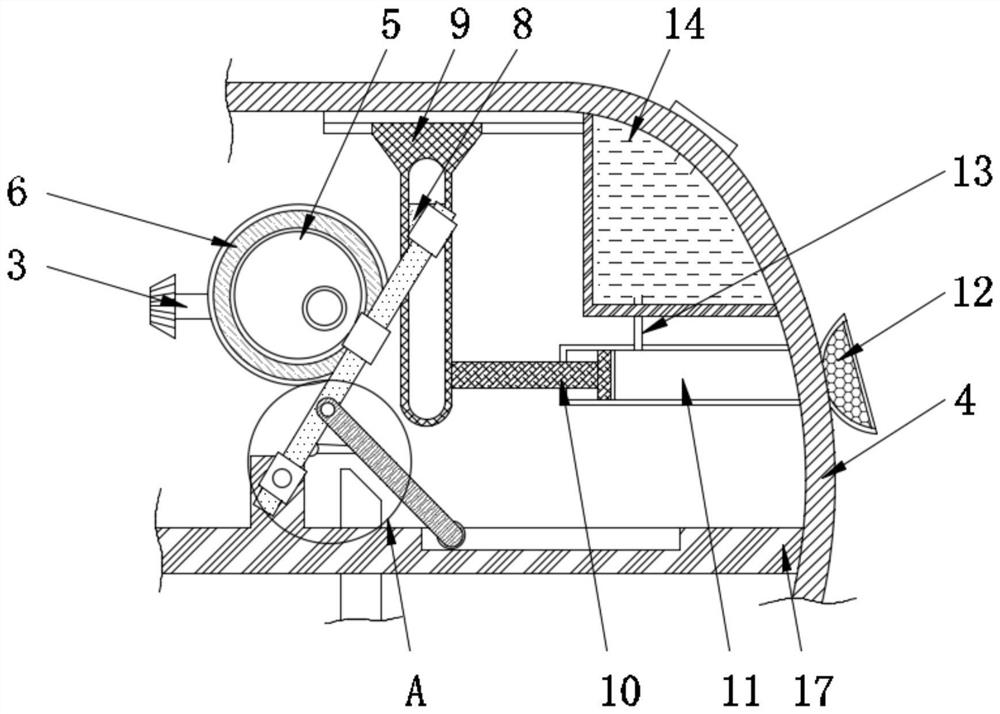

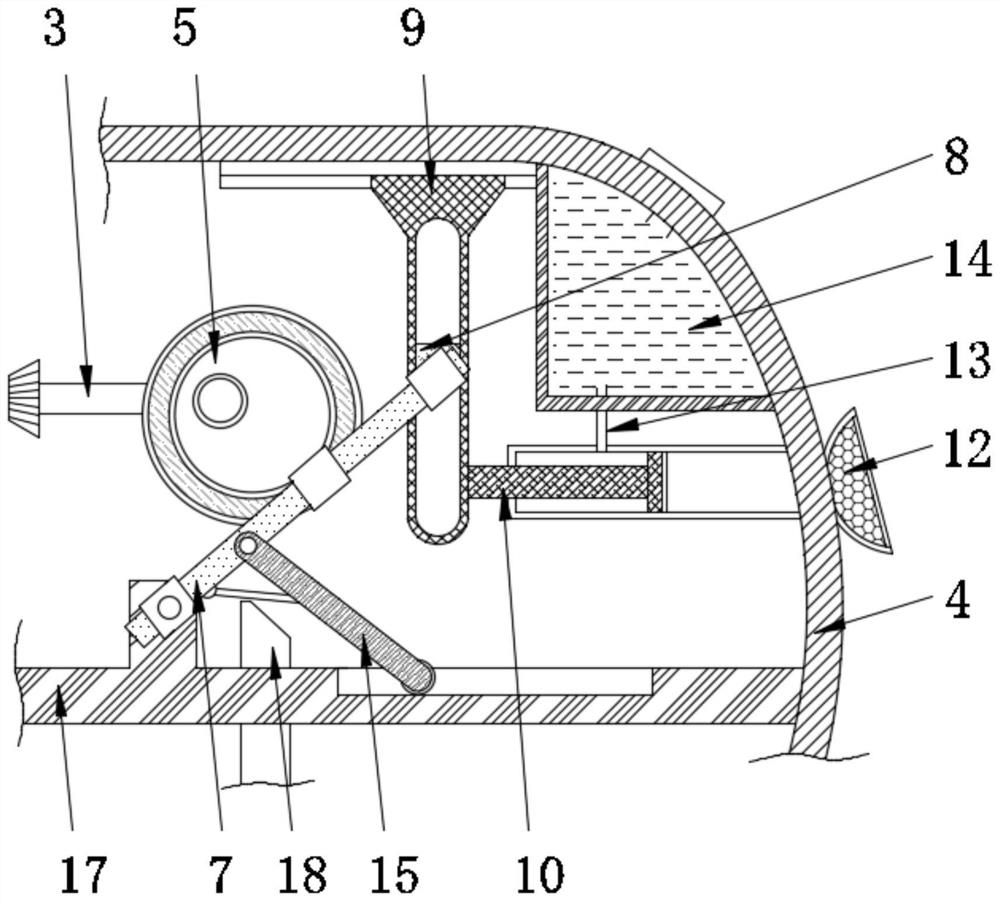

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The invention provides a wind-driven automatic spray dust removal device in a building foundation pit, as attached figure 1 to attach Figure 5 Shown: including the rotating shaft 1, the outer surface of the rotating shaft 1 is fixedly equipped with a fan blade frame 2, the fan blade frame 2 runs through the upper surface of the processing chamber 4, and the bottom end of the fan blade frame 2 is meshed with a bevel gear rod 3, and the bevel gear The end of the rod 3 meshes and rotates with a disk 5, and the bottom end of the blade frame 2 and the rear surface of the disk 5 are provided with bevel gears, which are driven by the rotating shaft 1 to rotate, and the meshing rotation between the bevel gears The purpose of driving the rotation of the disk 5 is that the bevel gear rod 3 is arranged symmetrically on the left and right sides with the center of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com