Automatic solar silicon wafer cutting machine

A technology for solar silicon wafers and cutting machines, used in laser welding equipment, climate sustainability, manufacturing tools, etc., can solve the problems of affecting cutting accuracy, large vibration amplitude, and low cutting quality, and improve practicability and reliability. , improve practicality and practicality, improve the effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

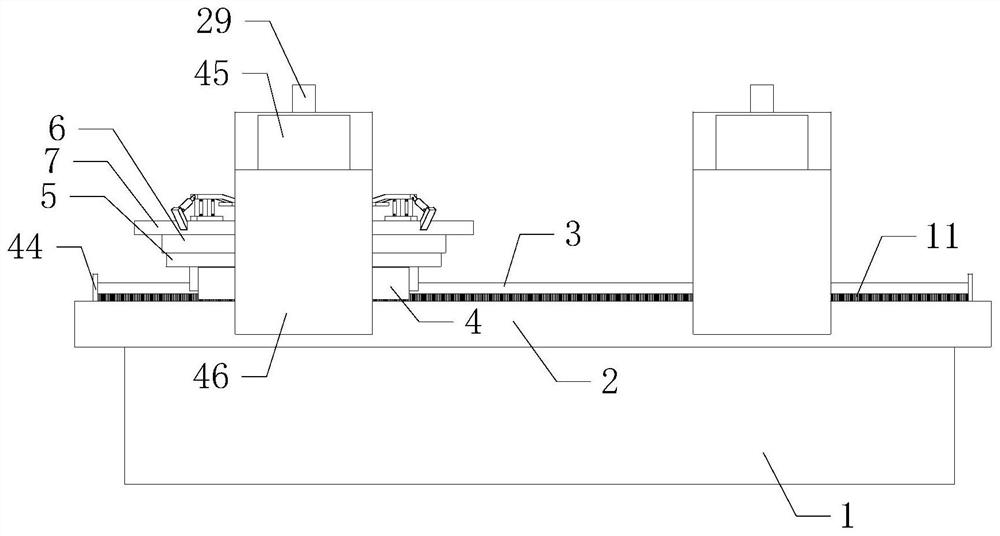

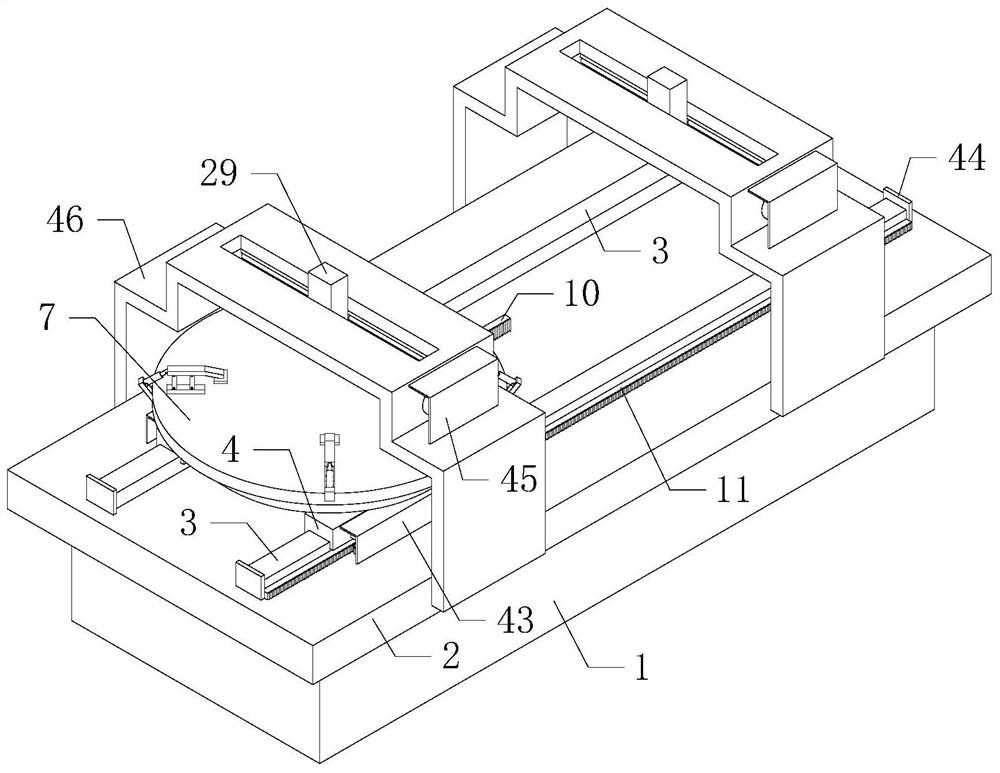

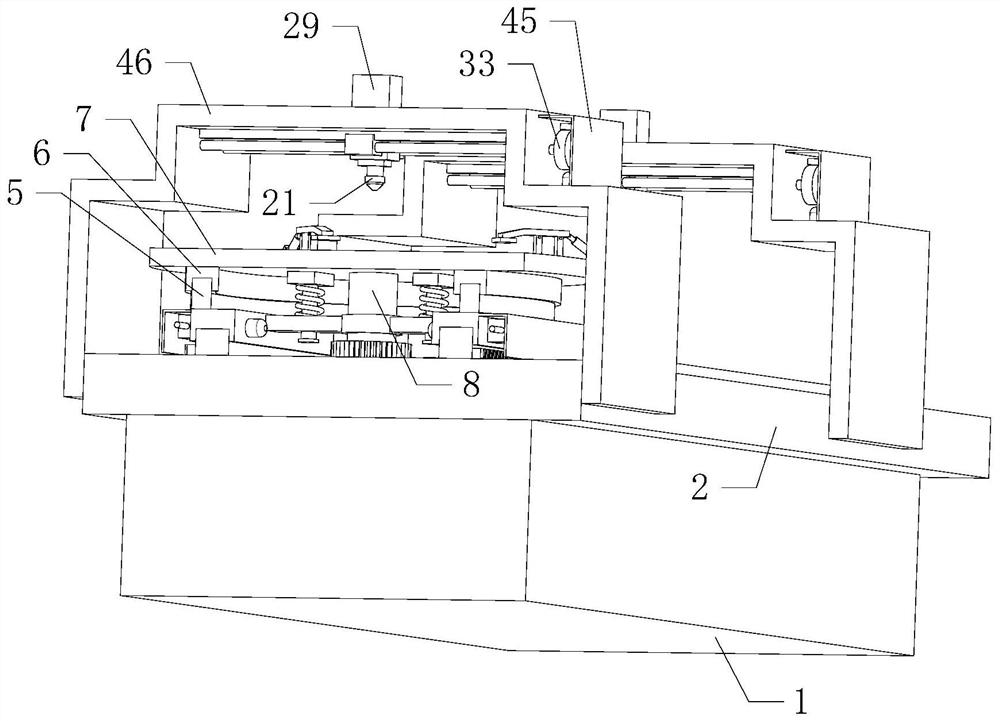

[0024] Such as Figure 1 to Figure 9 As shown, the solar silicon wafer automatic cutting machine of the present invention, when it is working, the working mode of the power device is to open the first motor 20, and the first motor 20 can drive the double output shaft speed reducer 19 to run, and the double output shaft speed reducer 19 Drive two groups of second bevel gears 16 to rotate through two groups of second rotating shafts 17, multiple groups of second fixing frames 18 can support two groups of second rotating shafts 17, two groups of second bevel gears 16 are connected with two groups of first bevel gears respectively Gears 15 mesh, two groups of second bevel gea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap