Spindle unit

A spindle and outer peripheral surface technology, applied in the field of spindle units, can solve problems such as reduced productivity and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

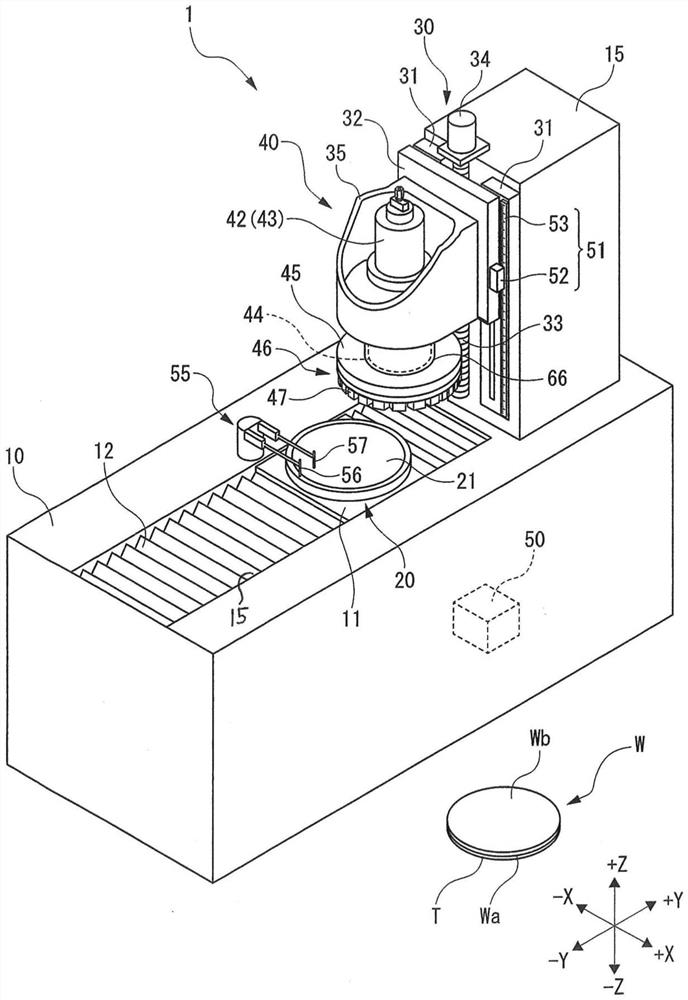

[0022] figure 1 The shown grinding apparatus 1 is an apparatus for performing grinding processing on a wafer W as a workpiece. figure 1 The wafer W shown is, for example, a circular semiconductor wafer. A plurality of devices (not shown) are formed on the front surface Wa of the wafer W. As shown in FIG. Wa on the front figure 1 The center faces downward and is protected by affixing a protective tape T. The back surface Wb of the wafer W is a surface to be processed which is subjected to grinding.

[0023] The grinding apparatus 1 has a base 10 extending in the Y-axis direction, and a column 15 erected on the +Y direction side of the base 10 . A rectangular opening 15 extending in the Y-axis direction is formed on the upper surface of the base 10 . This opening 15 is covered by a moving plate 11 and a corrugated waterproof cover 12 .

[0024] A chuck table 20 is disposed so as to penetrate through the moving plate 11 . The chuck table 20 is a disk-shaped table for holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com