Flame-retardant thermoplastic elastic crash pad and preparation method thereof

A thermoplastic elastic and anti-vibration pad technology, which is applied in the field of anti-vibration materials, can solve the problems of poor elastic properties of TPI and cannot meet the requirements of wide use, etc., and achieve the effect of small compression set, excellent shock absorption effect and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

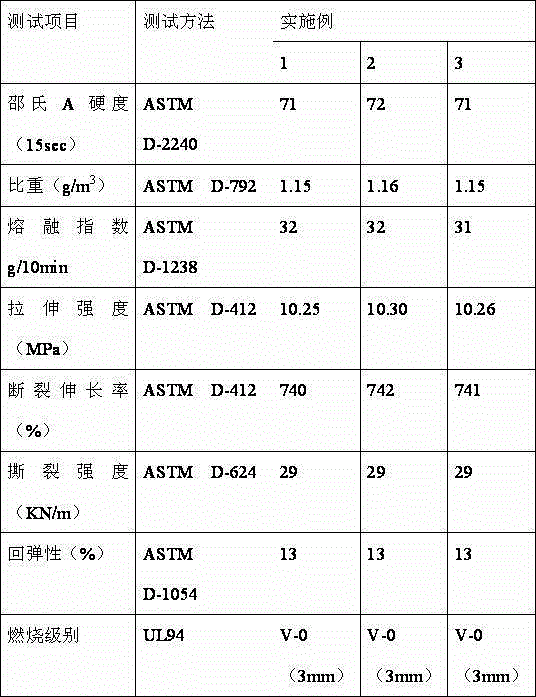

Examples

Embodiment 1

[0023] A flame-retardant thermoplastic elastic shockproof pad is characterized in that the components of the raw materials are composed as follows in parts by weight:

[0024] 45 parts of hydrogenated styrene butadiene copolymer L606, 20 parts of polyisoprene resin, 30 parts of SIS resin, 6 parts of EPDM rubber-maleic anhydride graft, 3 parts of naphthenic rubber oil , 7 parts of flame retardant compounded with 30wt% dipentaerythritol alkane aluminum hypophosphite / polymelamine uric acid compound, 5 parts of mineral fillers composed of talcum powder and mica powder according to the weight ratio of 3:4, three ( 0.3 parts of 2,4-di-tert-butylphenyl) phosphite, and 0.6 parts of silicone powder.

Embodiment 2

[0026] A flame-retardant thermoplastic elastic shockproof pad is characterized in that the components of the raw materials are composed as follows in parts by weight:

[0027] 50 parts of hydrogenated styrene butadiene copolymer L606, 22 parts of polyisoprene resin, 35 parts of SIS resin, 7 parts of EPDM rubber-maleic anhydride graft, 4 parts of naphthenic rubber oil , 8 parts of flame retardant compounded with 35wt% dipentaerythritol alkane-based aluminum hypophosphite / polymelamine uric acid salt, 7 parts of mineral fillers composed of talcum powder and mica powder according to the weight ratio of 3:4, three ( 0.4 parts of 2,4-di-tert-butylphenyl) phosphite, and 0.7 parts of silicone powder.

Embodiment 3

[0029] A flame-retardant thermoplastic elastic shockproof pad is characterized in that the components of the raw materials are composed as follows in parts by weight:

[0030] 55 parts of hydrogenated styrene butadiene copolymer L606, 25 parts of polyisoprene resin, 40 parts of SIS resin, 8 parts of EPDM rubber-maleic anhydride graft, 5 parts of naphthenic rubber oil , 9 parts of flame retardant compounded with 40wt% dipentaerythritol alkane-based aluminum hypophosphite / polymelamine uric acid salt, 8 parts of mineral fillers composed of talcum powder and mica powder according to the weight ratio of 3:4, three ( 0.5 parts of 2,4-di-tert-butylphenyl) phosphite, and 0.8 parts of silicone powder.

[0031] The raw material of embodiment 1-3 is prepared according to the following preparation method

[0032] A preparation method of a flame-retardant thermoplastic elastic shockproof pad is characterized in that it specifically comprises the following steps:

[0033] (1) Carrier inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com