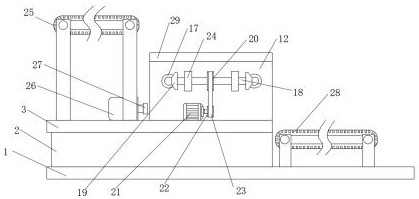

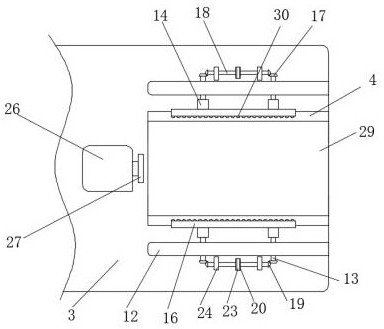

Automatic board feeding device for wooden artificial board production

A wood-based panel and automatic technology, applied in the field of panel processing, can solve the problems of increasing the working intensity of the staff, failing to meet market demand, reducing the efficiency of wood panel processing, etc., to achieve the effects of improving conveying efficiency, preventing damage, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

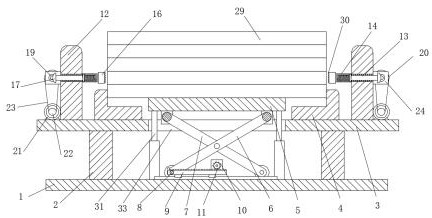

[0031] This embodiment is improved on the basis of Embodiment 1: the lifting assembly includes a driving motor 10 fixedly connected to the top of the base plate 1, the output shaft of the driving motor 10 is fixedly connected to a gear 11, and the bottom sides of the lifting plate 5 are respectively connected in rotation with The first U-shaped plate 6 and the second U-shaped plate 7, the first U-shaped plate 6 and the second U-shaped plate 7 are rotatably connected at the center of one side close to each other, and the first U-shaped plate 6 is rotatably connected at the side close to each other There is the same connecting rod 8, the outer wall of the connecting rod 8 is fixed with a rack 9, the bottom of the rack 9 is slidably connected to the top of the bottom plate 1, the rack 9 and the gear 11 are meshed, and a rectangular groove is arranged in the workbench 3 33. The clamping assembly includes two fixed plates 12 fixed on the top of the workbench 3, one side of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com