Aerated concrete block autoclave group

A kind of technology of aerated concrete and autoclave, which is applied in the direction of ceramic molding machine and manufacturing tools, which can solve the problems of not very tight locking, large steam leakage, and steam waste, so as to enhance the sealing performance and reduce the steam leakage , to avoid the effect of wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present application discloses an autoclave set of aerated concrete block, adopting the following technical scheme:

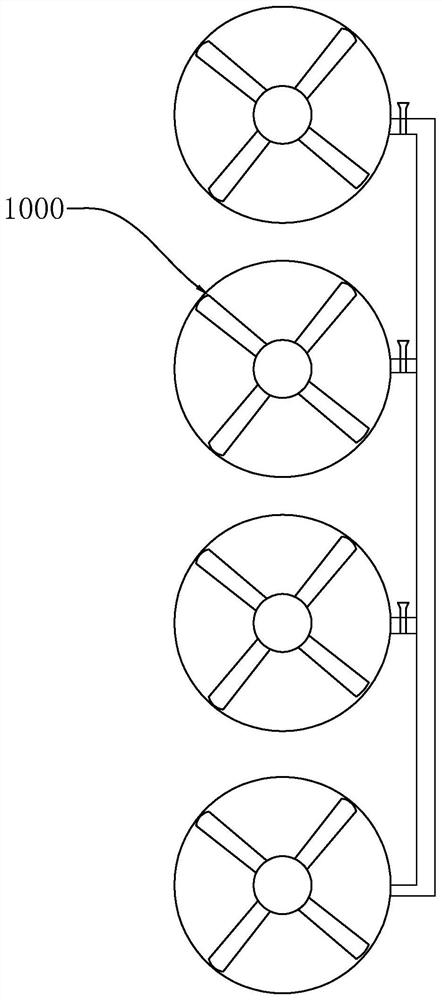

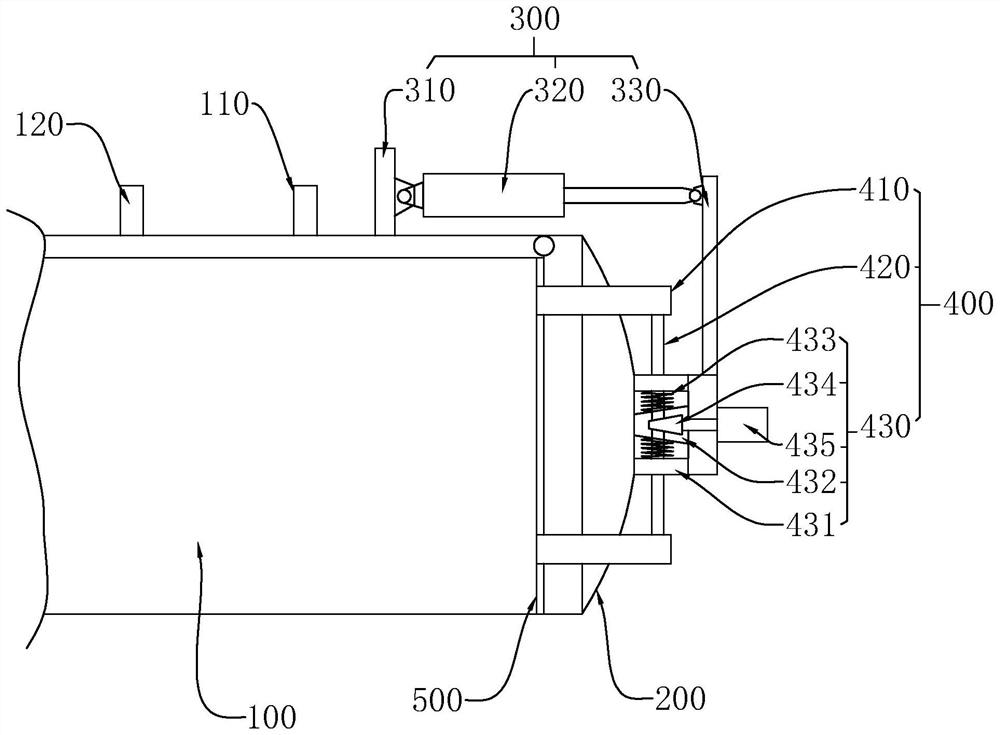

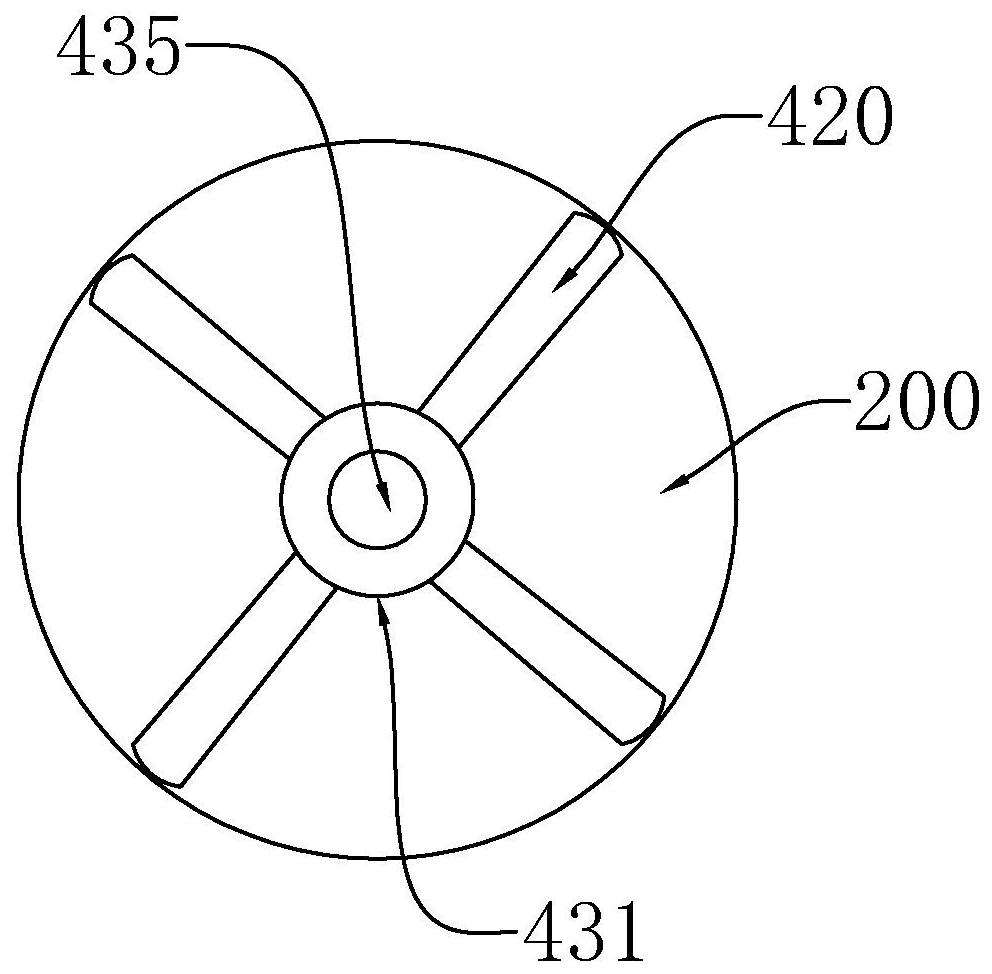

[0036] A kind of aerated concrete block autoclave group, refer to figure 1 and figure 2 , including a plurality of autoclaves 1000, the autoclave 1000 that is first autoclaved and the subsequent multiple autoclaves 1000 communicate with the subsequent multiple autoclaves 1000 through pipelines and valves; Carry out steam supply, for example, the first autoclave 1000 can supply steam to the second, the third, the fourth autoclave 1000 when the pressure is released, and the second autoclave 1000 can supply steam to the third and the fourth autoclave 1000 Steam supply to avoid waste of steam. Each autoclave 1000 includes a kettle body 100 and a kettle cover 200 hinged at the opening end of the kettle body 100, wherein the bottom of the kettle body 100 is provided with a track, which enables the transport trolley to walk on the track, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com