Electric coaxial multi-rotor helicopter based on contra-rotating double-rotor motor

A dual-rotor motor and dual-rotor technology, used in rotorcraft, motor vehicles, and transmissions that drive multiple propellers, etc., can solve the problems of no change, mutual interference between rotors, poor endurance, etc. , easy control, the effect of large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

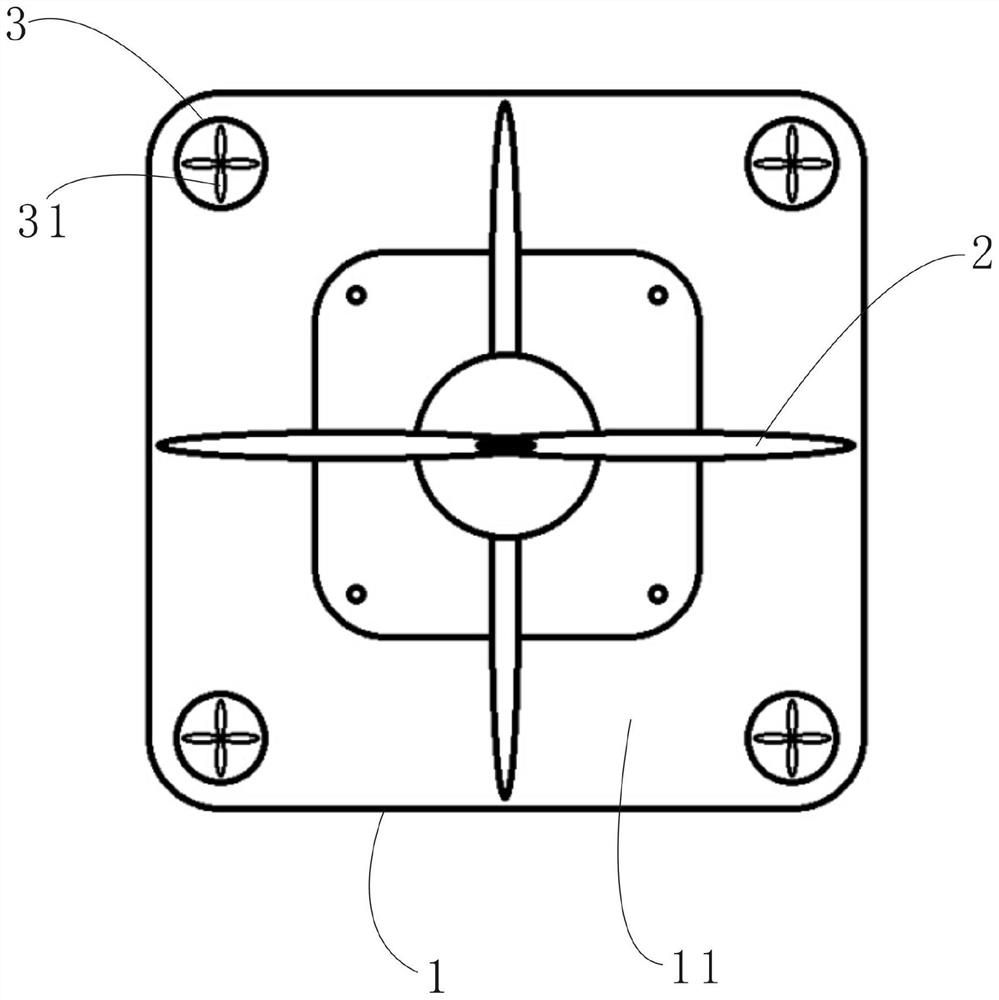

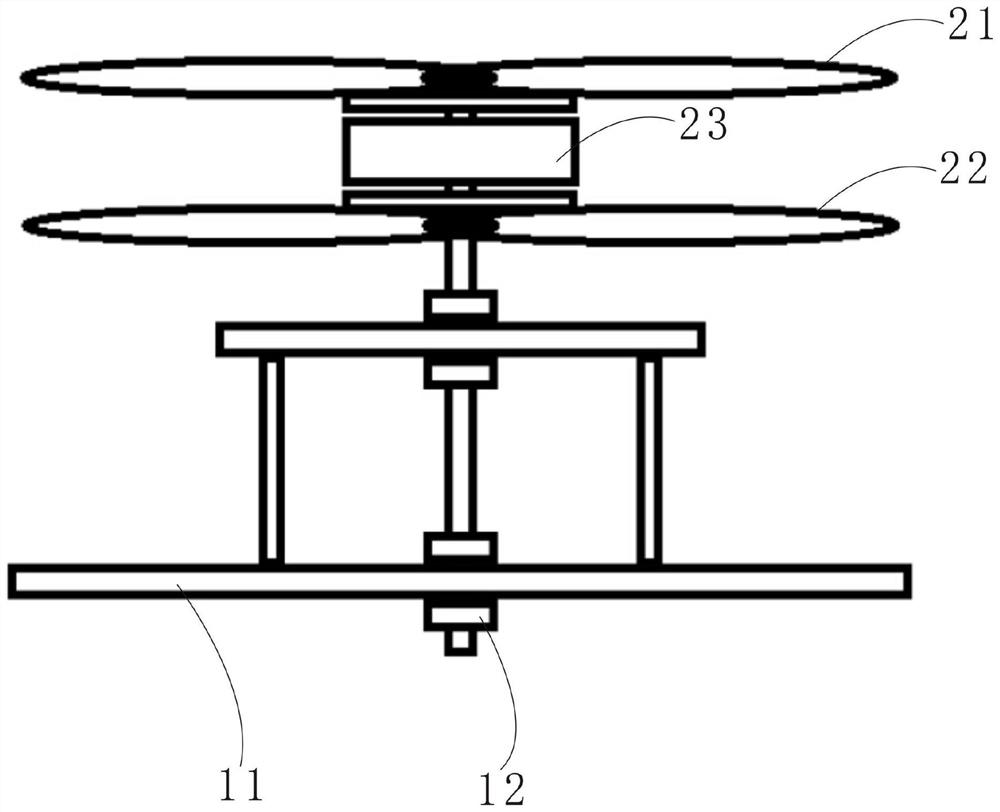

[0052] The following is based on Figure 1-2 Describe in detail an electric coaxial multi-rotor helicopter based on counter-rotating dual-rotor motors according to an embodiment of the present invention.

[0053] Such as Figure 1-2 As shown, the embodiment of the present invention discloses an electric coaxial multi-rotor helicopter based on a counter-rotating dual-rotor motor, which specifically includes:

[0054] fuselage 1;

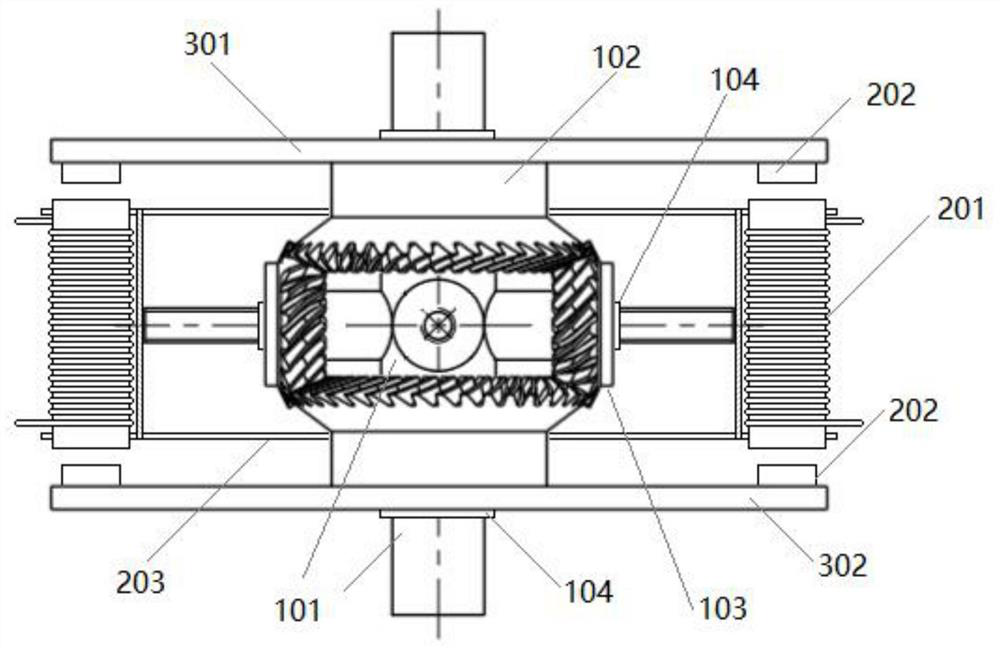

[0055] The main rotor system 2, the main rotor system 2 is located at the upper center position of the fuselage 1 and is fixed with the fuselage 1 by a fastener 12, the main rotor system 2 includes a coaxial upper rotor 21 and a lower rotor 22, placed on the upper rotor 21 and the lower rotor 22 are used to make the upper rotor 21 and the lower rotor 22 realize the counter-rotating dual-rotor motors that rotate at the same speed in the opposite direction; the main rotor system 2 is used to provide the main flight power for the helicopter;

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com