Gas filling device

A kind of equipment and gas technology, applied in the field of gas filling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

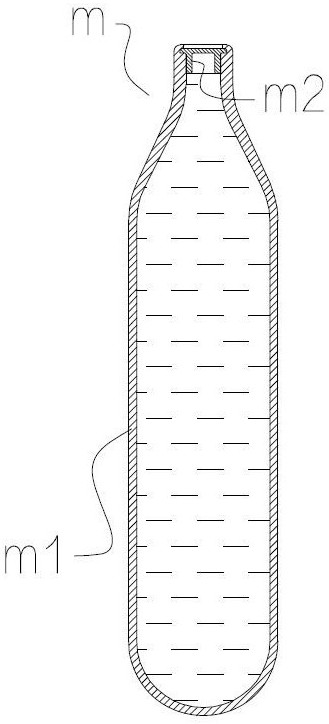

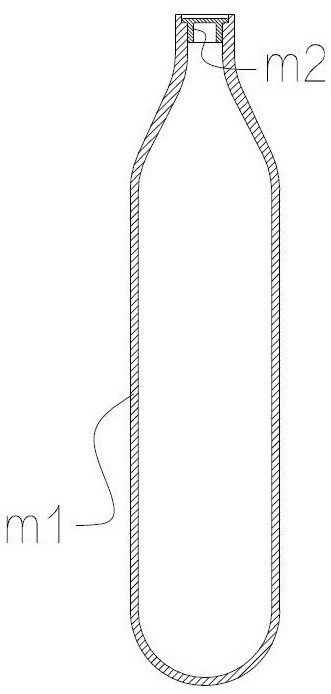

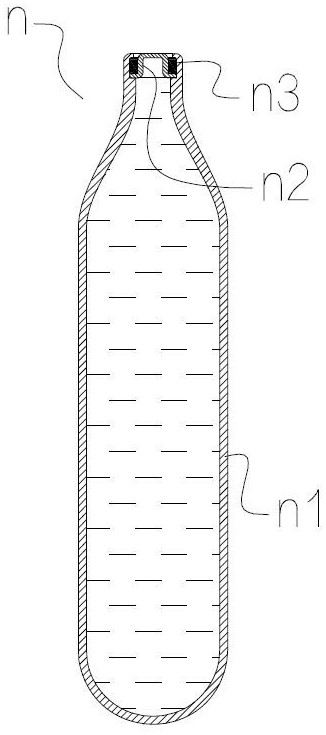

[0056] In this example, the production image 3 The filling equipment for the gas bomb n shown in is described as an example. Such as Figure 5 , Figure 6 and Figure 7 As shown, a gas filling device includes a frame 1 and a turntable mechanism 2 fixed on the frame 1 . The turntable mechanism 2 includes a cam divider 22 with a motor 21, the output end of the cam divider 22 can rotate and stop intermittently, the output end of the cam divider 22 is arranged vertically, and the output end of the cam divider 22 is fixed with Disc-shaped carrier plate 23 . The center line of the carrier plate 23 is arranged coaxially with the rotation axis of the carrier plate 23 , the carrier plate 23 has a horizontally arranged surface, and the rotation direction of the carrier plate 23 in this embodiment is clockwise. The filling equipment of this embodiment also includes twelve station actuators arranged around the rotation axis of the carrier plate 23, and these twelve station actuators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com